Contract Manufacturing

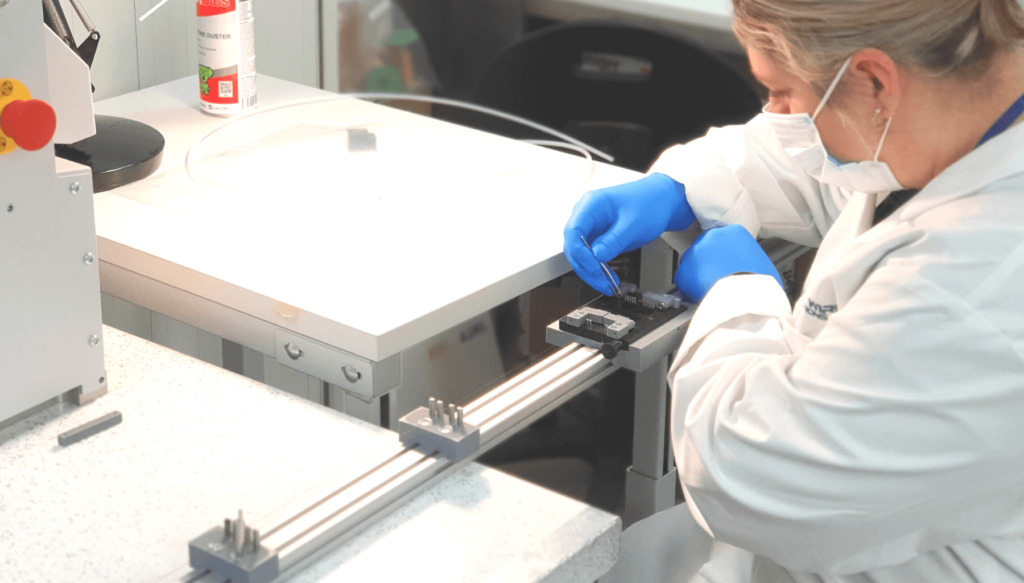

Laser Wire Solutions offers clients ISO 9001:2015 certified contract laser wire manufacturing services.

We use our expertise to offer a full production process, designed to meet your laser wire stripping requirements, and ensure that they are shipped and ready for use.

Why Choose Contract Manufacturing?

For some original equipment manufacturers (OEMs), investing in the capital equipment for stripping wires in-house isn’t possible and outsourcing to a third-party is more feasible.

By using our suite of automated manufacturing solutions, we can offer full production to meet our partners laser wire ablation requirements, shipped and ready to be used in various medical devices.

We are ready to support you.

Our Service, Your Advantage

We understand the importance of a strong production line and having the right capabilities to conduct the work to a high standard can make a real difference to the end product.

Find out how we are able to demonstrate our capability of providing you with high quality products.

iso certified

ISO 9001:2015

Our Contract Manufacturing service is ISO 9001 certified, meaning you will receive high quality standard products.

We have a robust quality control system in place, with high specification quality assurance tools to check each wire before it is shipped to our customers.

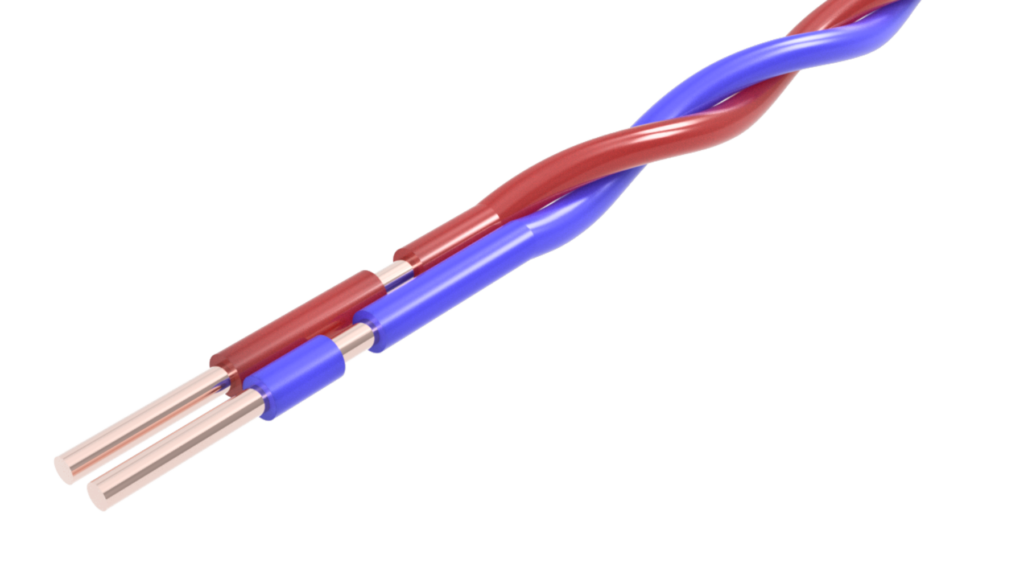

Wire & Cable Types

In our Contract Manufacturing business unit, we can handle a wide range of wire and cable types. The below is a selection of wires and cables we have experience stripping using laser technology:

- Single Core

- Twin Leads

- Twisted Pair

- Microwave Coaxial

- Ribbon Cable

- Flat Flexible Cables (FFC)

- Braided Multi-Conductor Cable

- Tape/Foil Wrapped Cable

- Micro-Coaxial

Insulation Materials

The type of insulation material used on the wire will affect the efficiency and effectiveness of the laser wire stripping process. Some common insulation materials that we have found are suitable for laser wire stripping include:

- Polyester

- Fiberglass

- PVC

- PTFE/Teflon

- Polyesterimide

- Tefzel

- Enamel Coated

- Polyethylene

- Polyimide/ Kapton