Aerospace & Defense

Large wire diameters and mature precision tools mean that sophisticated laser wire stripping tools are seldom needed. But there are some exceptions.

To make terminations to the conductors of a shielded multi-conductor cable, it’s necessary to remove a few inches of the cable jacket and peel back the shield, only possible using precision lasers.

Our Solutions

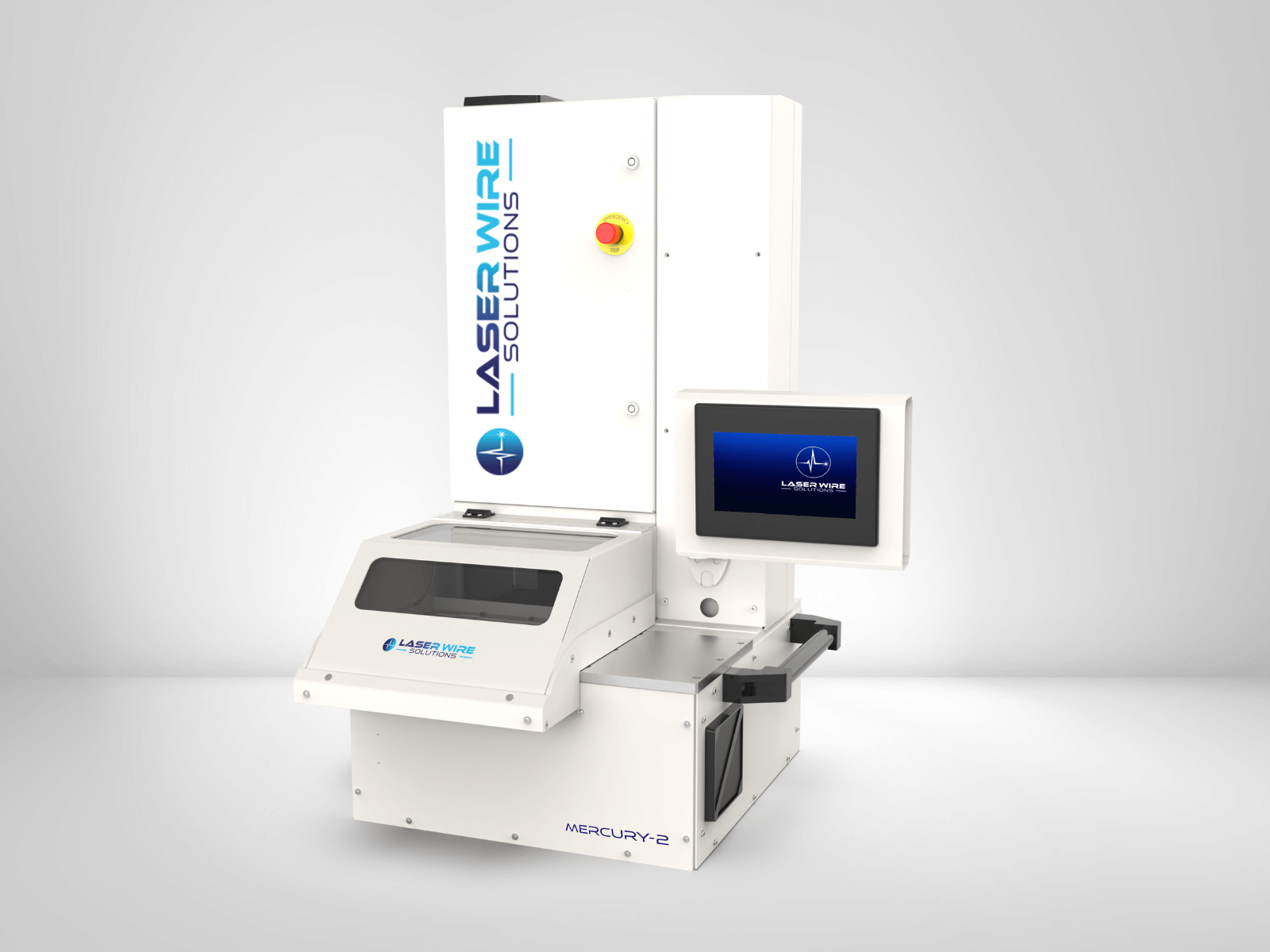

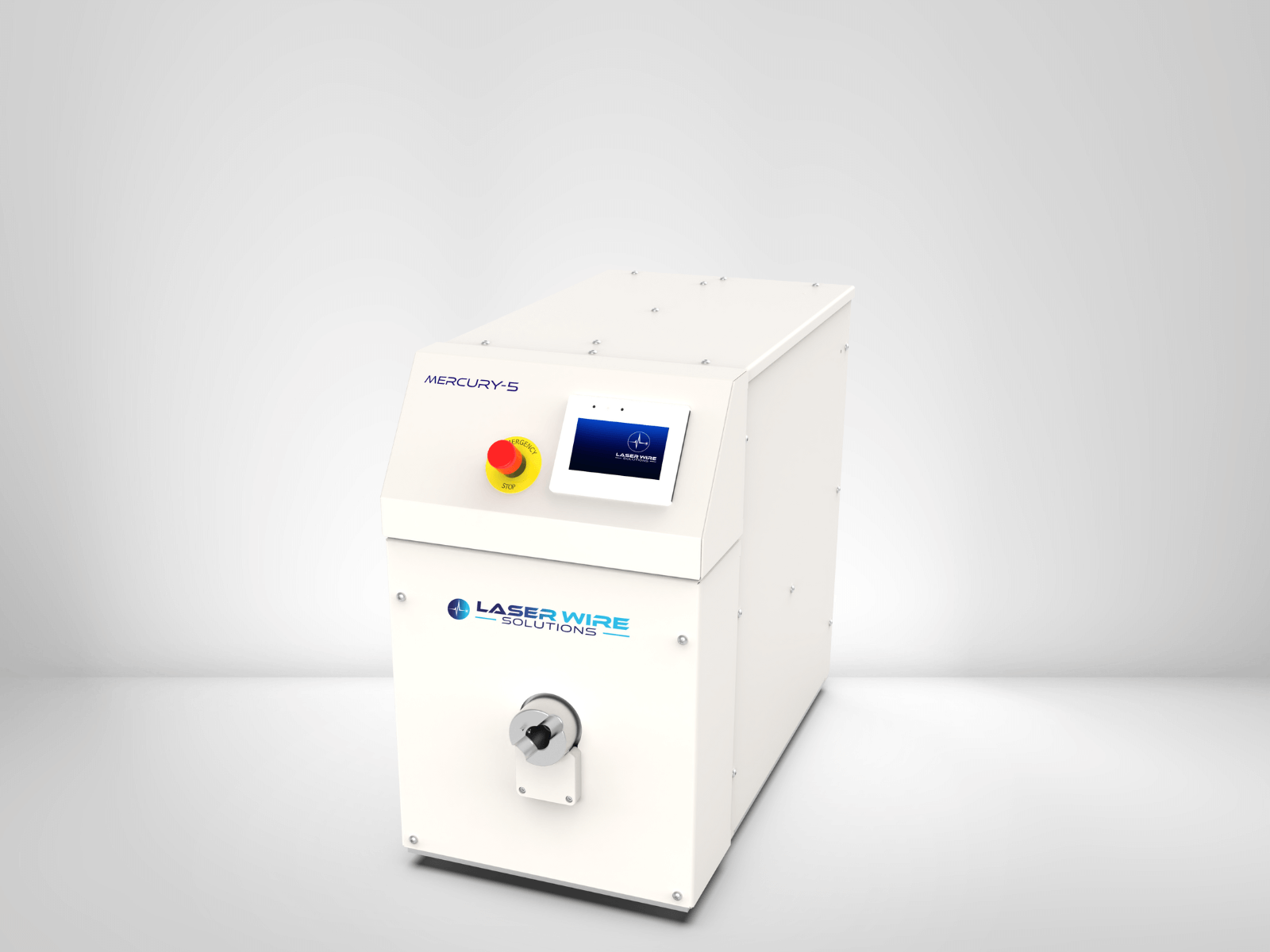

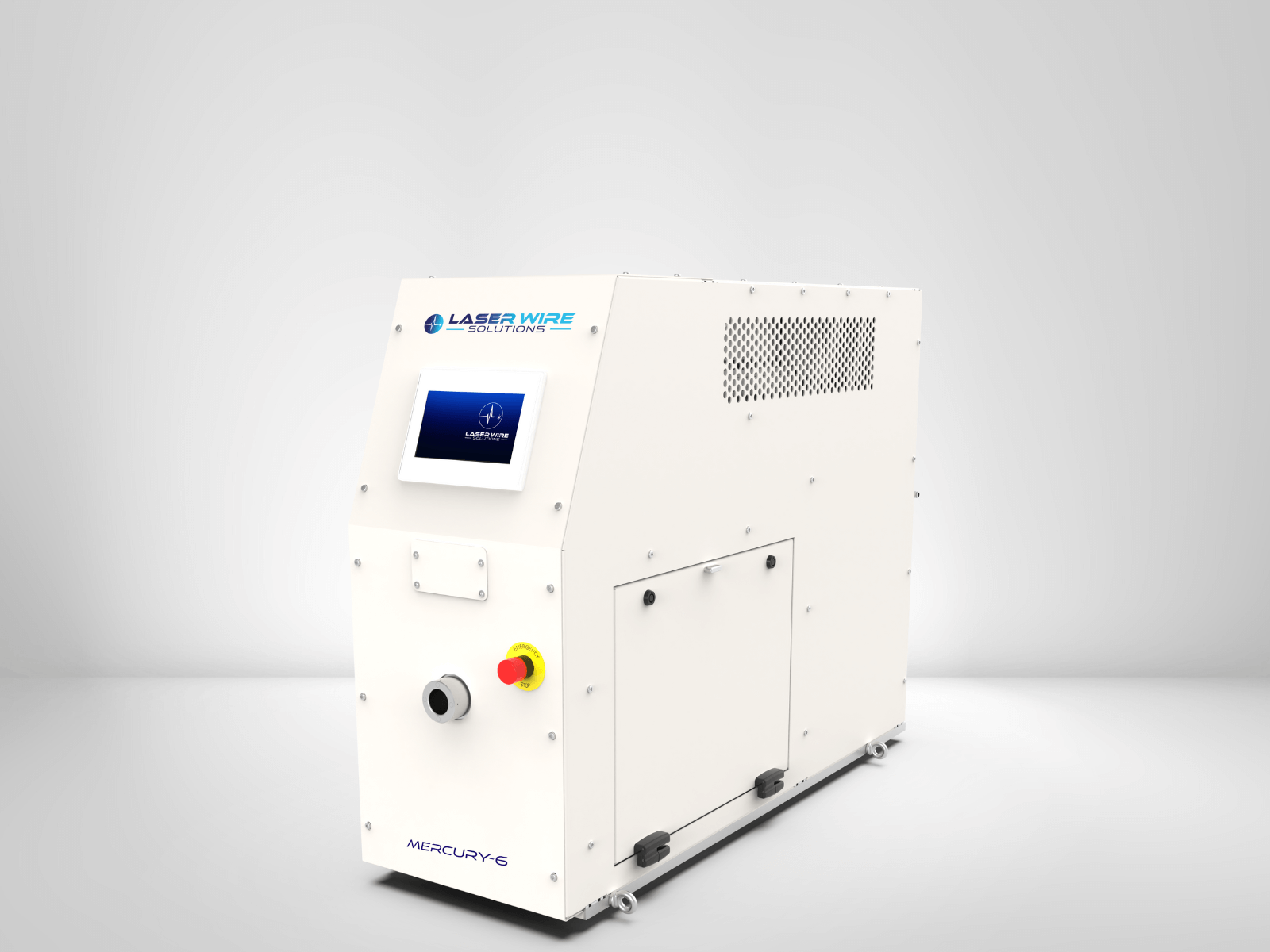

The Aerospace and Defense sectors have a wide range of wire constructions that are ideally suited to laser wire stripping.The common insulation types, such as PTFE, ETFE, XLETE and Kapton, are readily stripped by carbon dioxide laser technology, with Mercury-2 and Mercury-4 being the perfect solutions.

The vast majority of aerospace cabling is stripped today using high quality mechanical hand tools, or simple semi-automatic mechanical strippers. However, there are some key applications (below) where the benefits of laser wire stripping give a clear payback for the investment in the equipment.

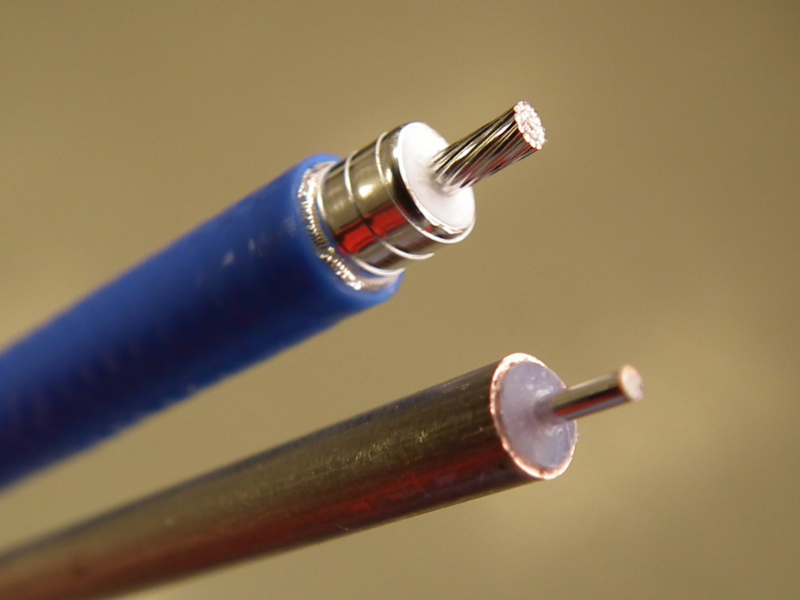

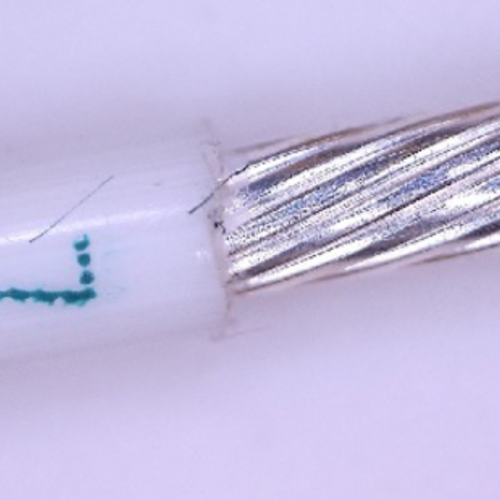

Twisted Shielded Multi-Conductors

Shielded cables typically need 1-3″ (25-75 mm) of jacket removed in order to peel back the shield to access the inner conductors. As these cables are not round, mechanical tools are unable to tackle the job of removing the insulation. Jacket materials are usually tight and cannot be slid off. Using a blade to cut around the cable is not sufficient – you would also have to use the blade to cut along the insulation to slit it. This raises a number of personnel safety issues as well as risks to damaging the cable itself.

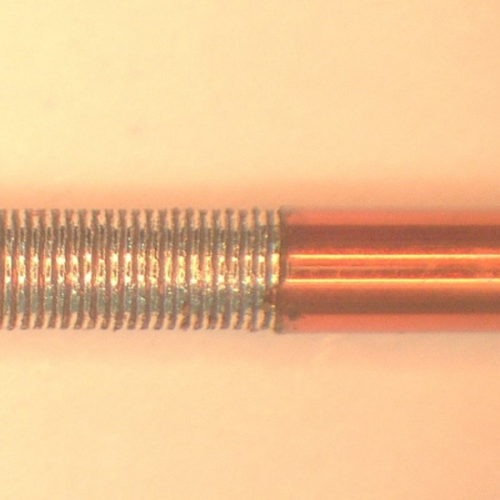

Tough Insulations

In critical areas of aircraft and defense vehicles it is necessary to use strengthened wire and cable constructions. This might be due to high temperature requirements, or to be able to handle severe weather and moisture. These constructions include Kapton – a polyimide film and fiber glass braids. Both are very tough and difficult to cut with mechanical blades. Fiber glass in particular is extremely difficult to cut without fraying and blunt blades very quickly. Examples of such wires are TKT constructions such as BMS13-58, Airbus CF wires and BMS 1360. Our Mercury laser wire stripper models are perfect for making nick-free perfect strips every time.

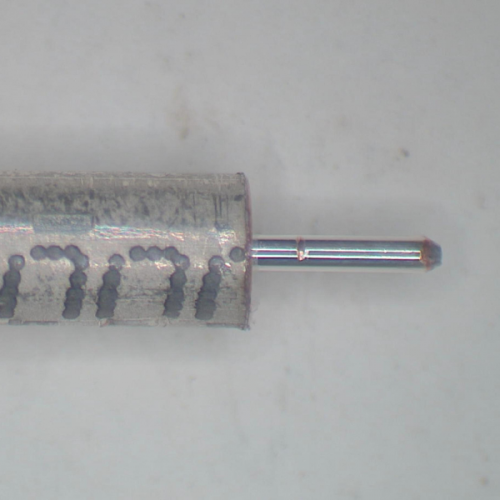

Microwave Cables

Microwave cabling is very common in defense vehicles. For the best possible performance it is critical that the conductor is not nicked during the stripping process. The Mercury systems are perfect for this application.