Automotive

With vehicle electrification a vastly growing business, our laser wire strippers are the only effective means of stripping high voltage, large diameter cables with multiple insulation layers.

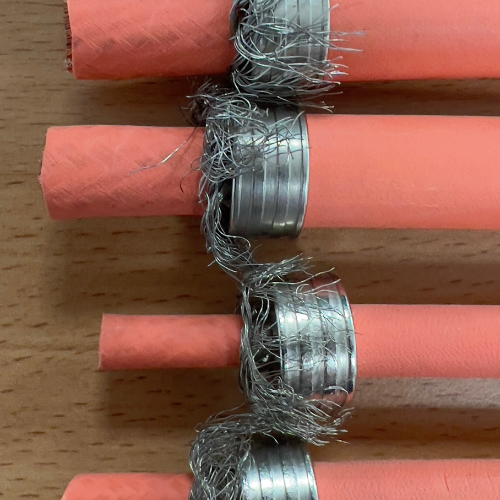

The increasing use of hairpin-designed magnet wires in motors and stators in the electrification of vehicles is creating a demand for more efficient removal of the insulation from such wires.

Our Solutions

With vehicle electrification a vastly growing business, our laser wire strippers are the only effective means of stripping high voltage, large diameter cables with multiple insulation layers. Hairpin designed magnet wires in motors and stators in the electrification of vehicles are creating a demand for more efficient removal of the enamel insulation from such wires.

Modern vehicle design is incorporating a large amount of data wiring as our requirements for information and connectivity increase. It is not uncommon to come across automotive applications where these more delicate data cables where conventional methods do not achieve the required high manufacturing volumes.

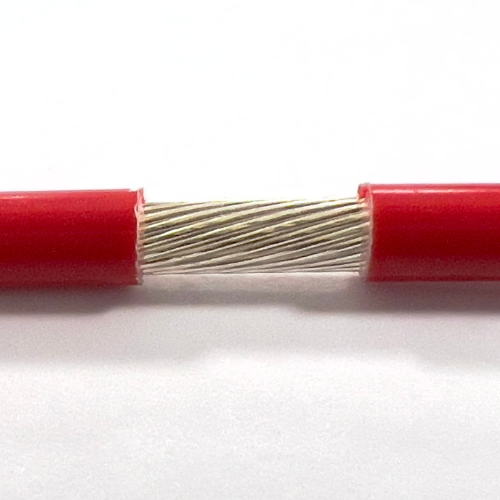

Electric Vehicle Cables

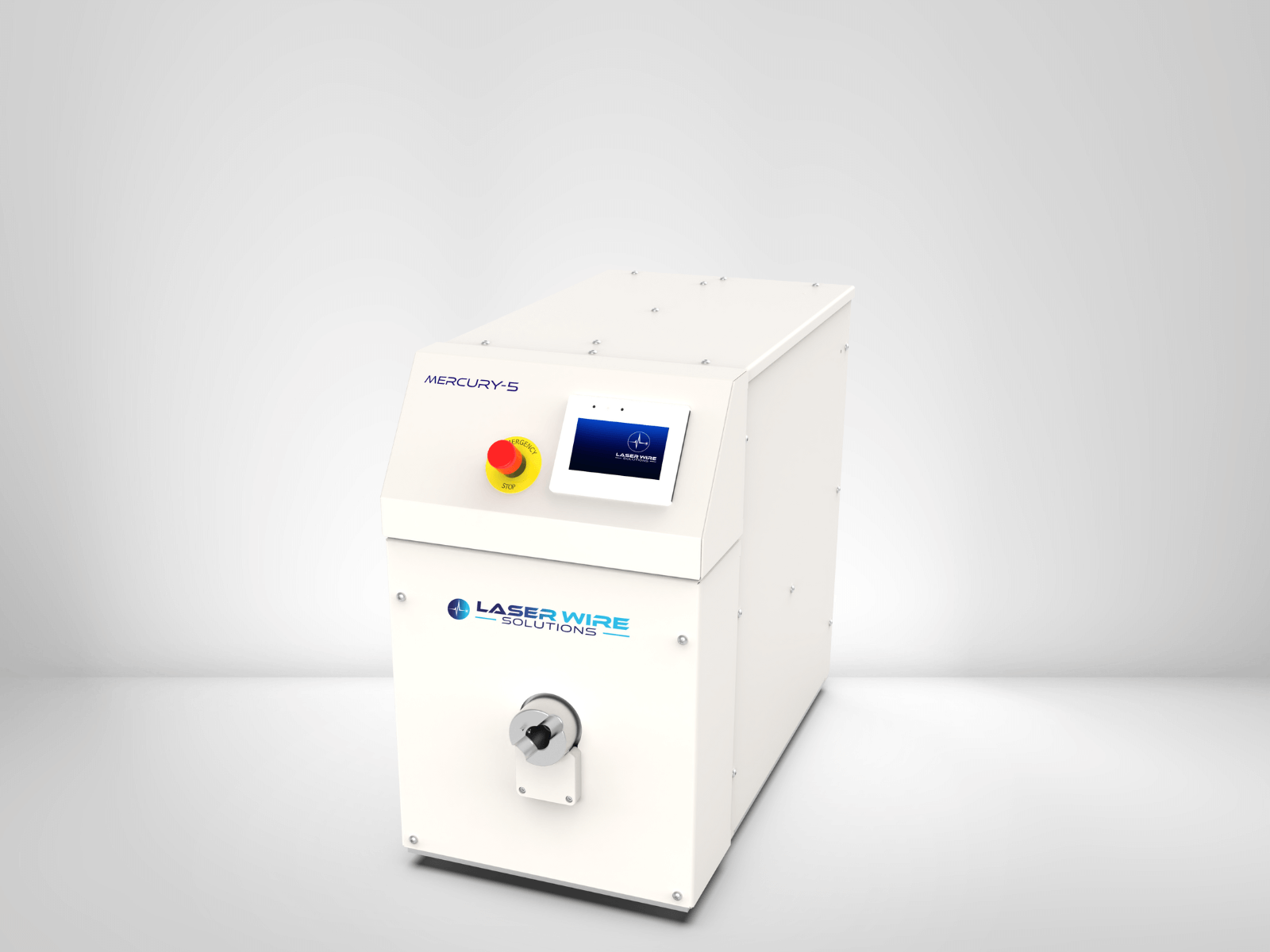

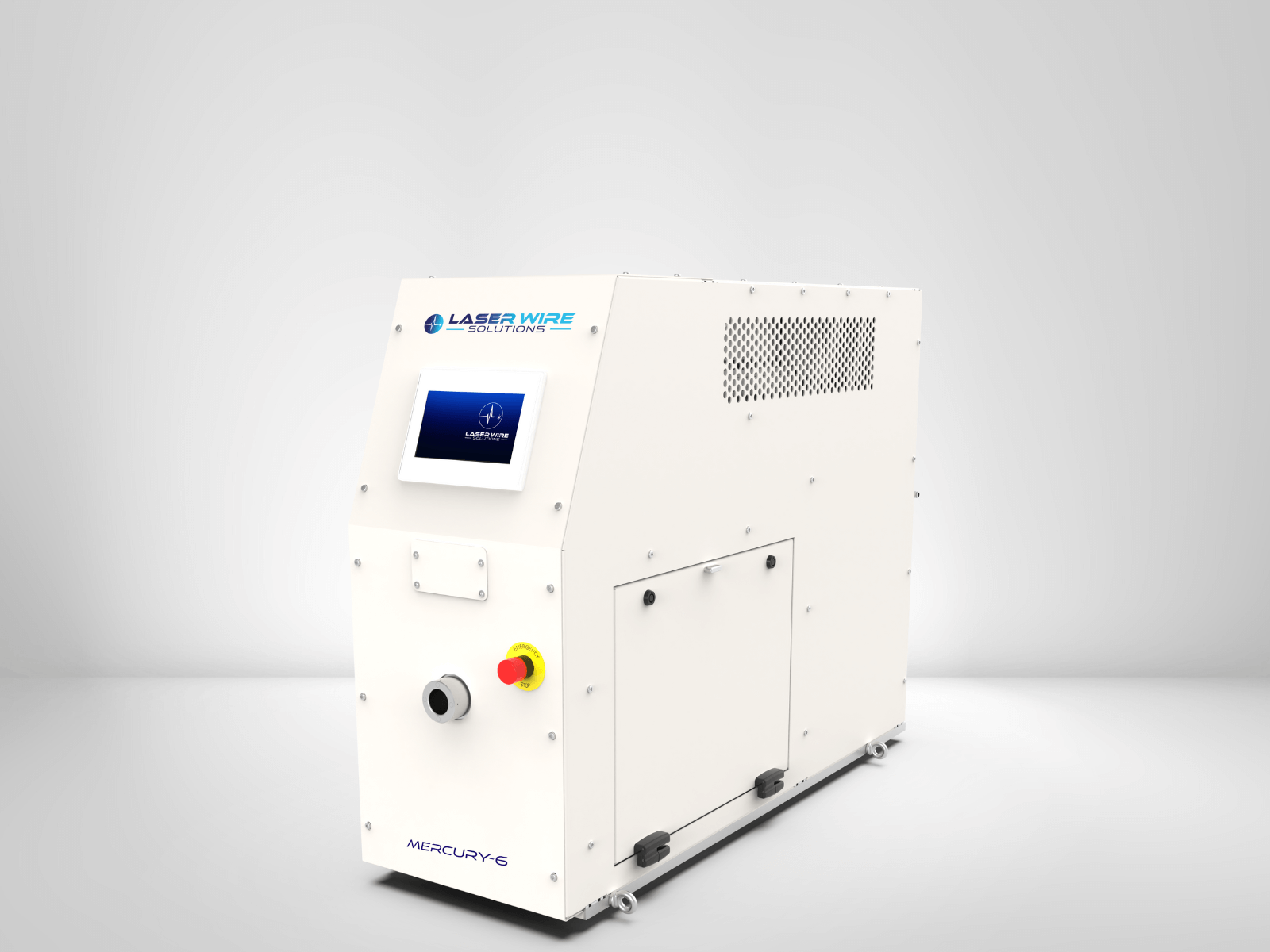

With vehicle electrification a vastly growing business, our laser wire strippers are the only effective means of stripping high voltage, large diameter cables with multiple insulation layers. With the design of our Mercury-5 and Mercury-6 laser machines, we have taken laser stripping to the next level. These are auto-focus machines that take the strain and scrappage cost out of stripping tough insulation from large diameter cables.

Flat Flexible Cable

Increasingly used due to its compact geometry. Auto wire stripping can be used for programmable window stripping or fold lines for fast change parts.

Data Cables

Modern car design is incorporating a large amount of data wiring as our requirements for information and connectivity increase. It is not uncommon to come across automotive applications where these more delicate data cables are having to be laser stripped as conventional mechanical tools are not achieving the required high yield.

Automated Processing

Due to the high volume, low cost nature of auto-wiring, most laser wire stripping applications benefit from automatic wire feeding by integrating seamlessly with other solutions through our in-line fixture options.