Eliminate Human Skill from Your Wire Processing

With lasers, there's no need to rely on your operators skill to improve the quality and yield for your products.

Join the top medical OEMs around the world that have already converted their wire processing to lasers with us.

- Consistent results

- No nick, no scrape

- Free inital sample

Eliminate Human Skill from Your Wire Processing

With lasers, there's no need to rely on your operators skill to improve the quality and yield for your products.

Join the top medical OEMs around the world that have already converted their wire processing to lasers with us.

- Consistent results

- No nick, no scrape

- Free inital sample

Introducing Odyssey-8, the Compact Single Wire Laser Stripper designed to handle the most intricate tasks with unparalleled speed and precision. Are you ready to elevate your wire-stripping process?

With no need for wire holding fixtures, a cycle time of less than 3 seconds, and the ability to strip wires under 0.2 mm in diameter, the Odyssey-8 redefines efficiency and precision.

The wire stripping machine you could fit in your suitcase, the Odyssey-8 slots effortlessly into any existing production line.

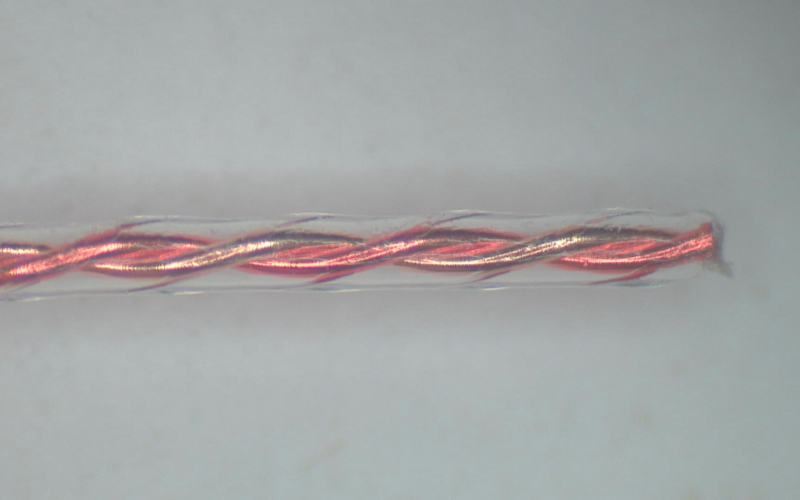

40 AWG twisted pair wire with an outer ETFE coating

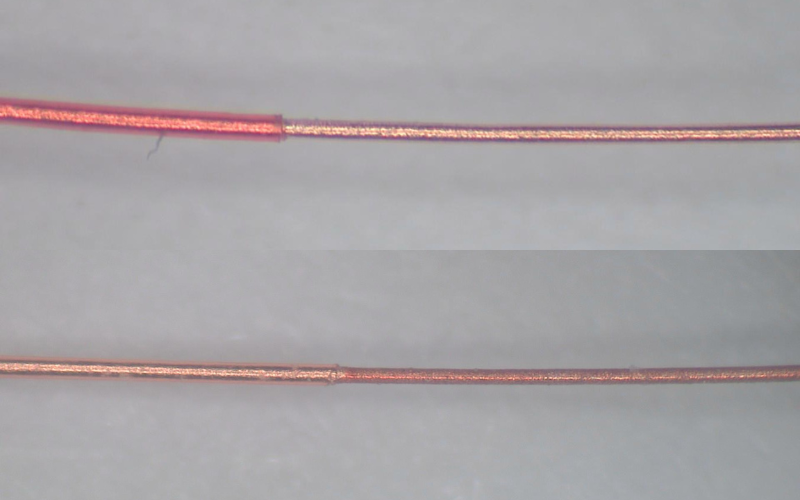

38 AWG twisted pair copper conductor with insulation layer

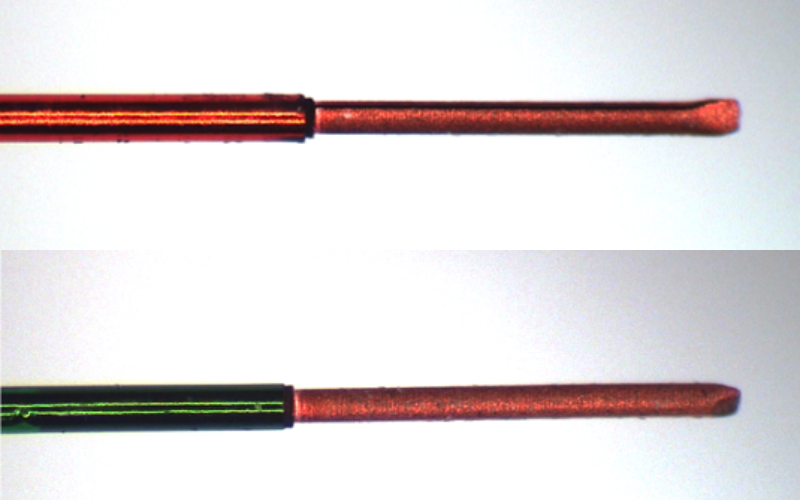

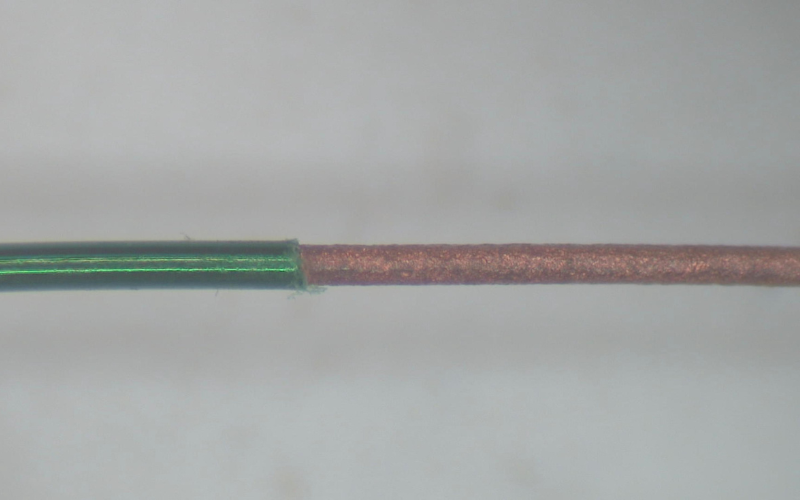

26 AWG magnet wire

Is the Odyssey-8 suitable for my application?

Whether you’re handling single, bifilar, or trifilar, the Odyssey-8 is the versatile wire processor that will make your production line smoother. The easy-to-use, recipe controlled system requires minimal training with your operators while ensuring consistent results in seconds. The machine can handle wires with a diameter of less than 0.2 mm (24 AWG) with a variety of materials with ease so it can be used for a wide range of applications.

No more heavy-duty machinery that takes up vital space in your factory. With a small footprint of 200 x 320 x 470 mm (LxWxH), the Odyssey-8 will slot straight into your production line on any bench wherever it is required. It comes with an integrated extractor, with a piece and laser hour counter to help guide servicing so you can keep your production line running.

By utilizing the power of laser processing you’ll be able to achieve high quality results, without having to rely on operator capability. It makes wire processing an easy task that can be easily completed in a matter of seconds.

While lasers can process most wire and cable materials, we recommend producing a small sample of wire for testing to ensure processing suitability.

Key Benefits of Laser Wire Processing

As simple and easy to use method that doesn't rely on operator competency