We partner closely with innovators in the medical device space, applying our wire and laser expertise to accelerate their automation journey, blending equipment and services in a flexible hybrid model.

We bring deep process expertise in the below applications to help medtech match the automation breakthroughs long realized in automotive manufacturing.

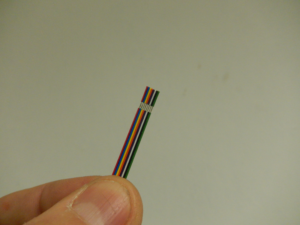

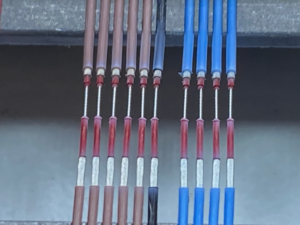

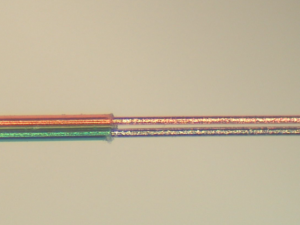

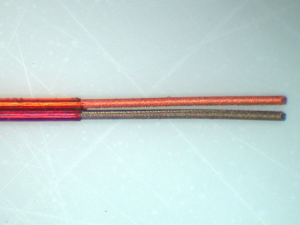

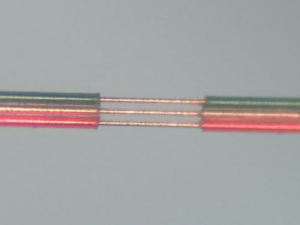

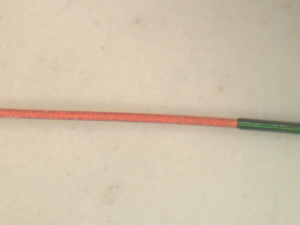

Unlike mechanical methods that rely on blades or abrasive wheels, or chemicals that introduce HSE risks, our laser wire stripping is entirely non-contact. This eliminates the risk of nicking or damaging ultra-fine conductors—vital for 36–50 AWG medical micro wires and cables where even a microscopic flaw can cause failure.

Our machines use controlled laser beams to deliver pinpoint accuracy down to the micron. You get repeatable, consistent results every time—even on insulation just a few microns thick. No mechanical wear, no tooling changes, and no calibration drift.

Laser stripping leaves no physical debris or contamination—ideal for cleanroom environments and Class II/III medical device production. This ensures regulatory compliance and eliminates risks associated with insulation flakes or particulates.

From R&D labs to high-volume production lines, our solutions scale with your needs: Benchtop machines for prototyping and small-batch runs, automated systems for fully integrated production cells. All while maintaining ultra-high precision at speed.

Our systems feature intuitive touchscreen controls and recipe management: Pre-programmed stripping patterns for common cable types, easy adjustment of laser power, spot size, and rotation, optional barcode scanning and traceability logging for FDA compliance

We support a wide range of insulation types and cable constructions: Polyimide, PTFE / FEP, Braided shields and micro-coax constructions

Request a free initial sample strip to test your wires or cables on our equipment—no obligation.

Our laser systems are designed with medical device manufacturing in mind, supporting both FDA and EU regulatory requirements.

Compliant with FDA CDRH standards (21 CFR 1040.10 & 1040.11)

Class 1 laser enclosures with safety interlocks and emergency stops

Built to meet CE directives: Machinery, EMC, and Low Voltage

Technical documentation available for audit support

Debris-free, sealed systems suitable for ISO Class 7/8 cleanrooms

Optional recipe tracking, barcode scanning, and validation support (IQ/OQ)

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, aerospace, defense and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2026 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.