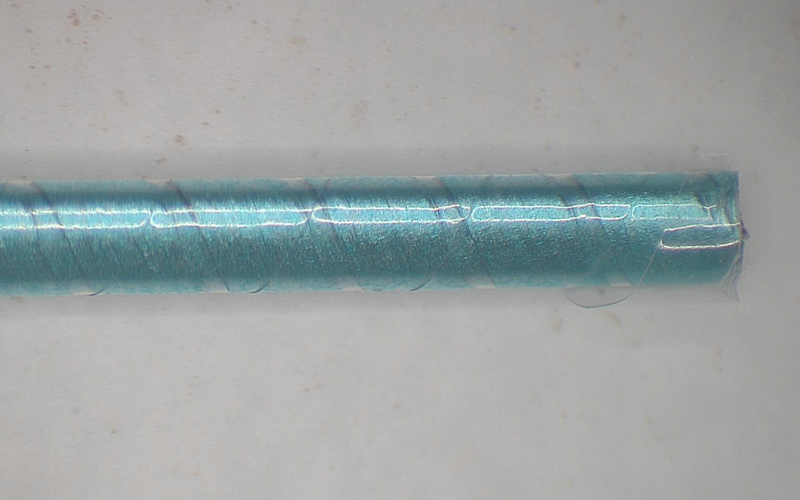

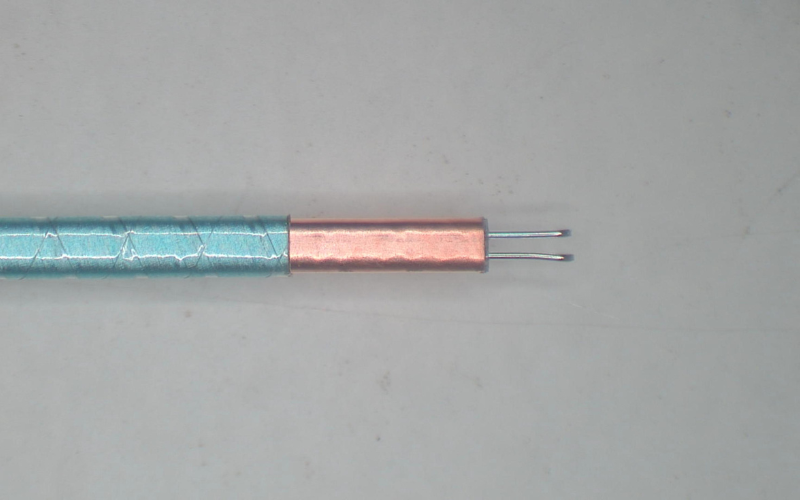

44 AWG Thermocouple with Copper Conductor

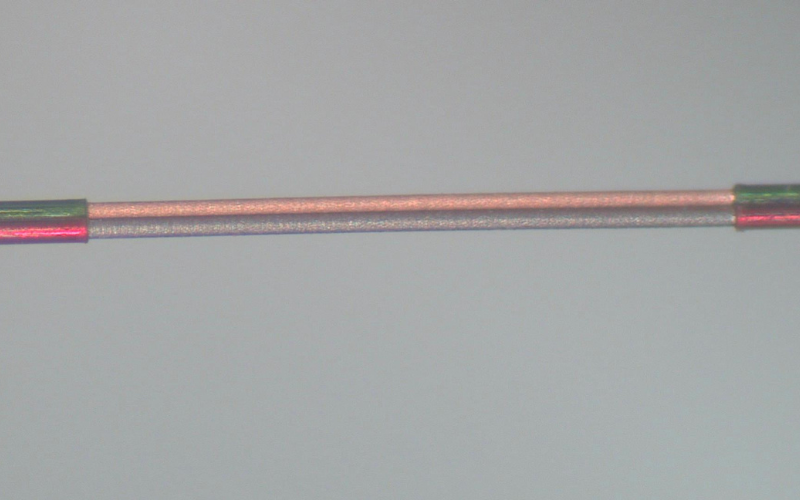

32 AWG Shielded Parallel Pair with Mylar and Foil Insulation

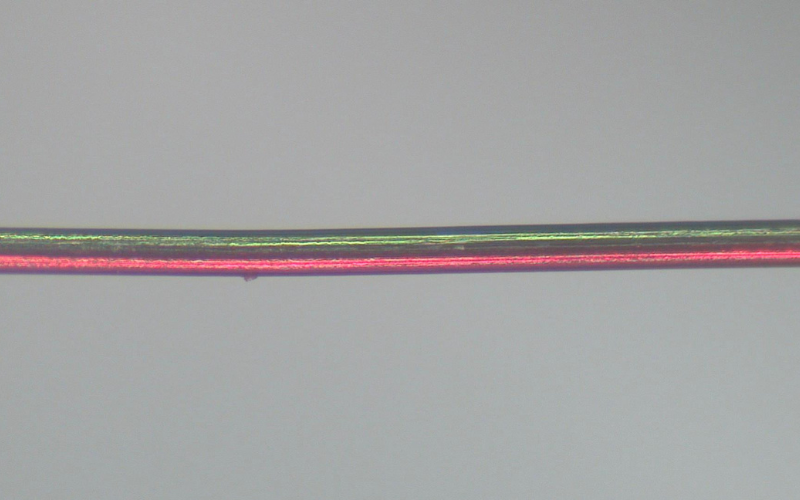

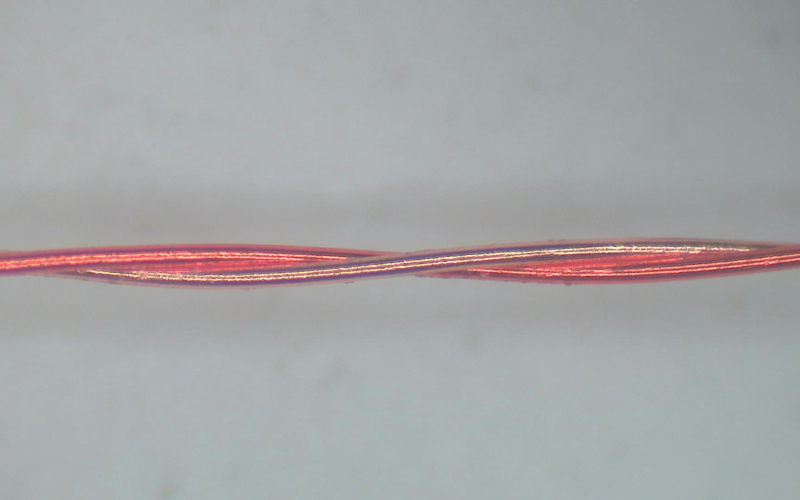

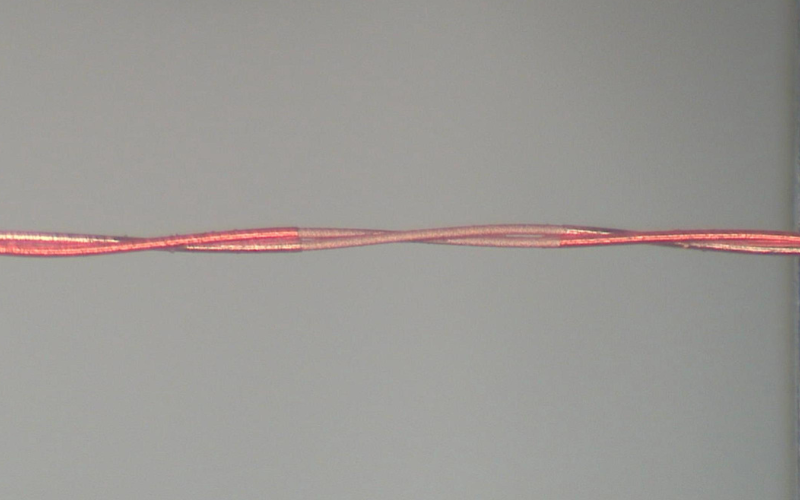

Twisted Enamel

Suitable Materials

Suitable Wire Types

Optional Extras

Every unit can be configured for your wire, your process, and your workspace

No risk of nicks, residue, or inconsistencies

Class 1 laser safety enclosures and intuitive controls mean peace of mind and productivity

Class 1 laser safety enclosures and intuitive controls mean peace of mind and productivity

Processing Length

Up to 70 mm (2.7″)**

Processing Area

Up to 70 mm (2.7″)**

Max. Wire

Diameter

<0.2 mm (0.007″)

Dimensions

(HxWxD)

1470 x 800 x 1180 mm

Weight

220 kg

Designed based on invaluable customer feedback, this machine not only surpasses its predecessors but also achieves faster processing speeds, redefining what precision and efficiency truly mean in wire stripping technology.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.