The Mercury-5 is designed to cross-cut and slit jackets and insulations of single conductor cables with an outer diameter between 6 mm and 20 mm. It has the ability to produce a slit length of 280 mm.

With no need for cable holding fixtures, a rapid cycle time, and an automatic cable centralizer, the Mercury-5 redefines efficiency and precision for large gauge cable stripping.

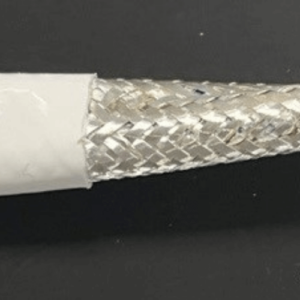

Multi-strand cable in silicon insulation with 9mm diameter

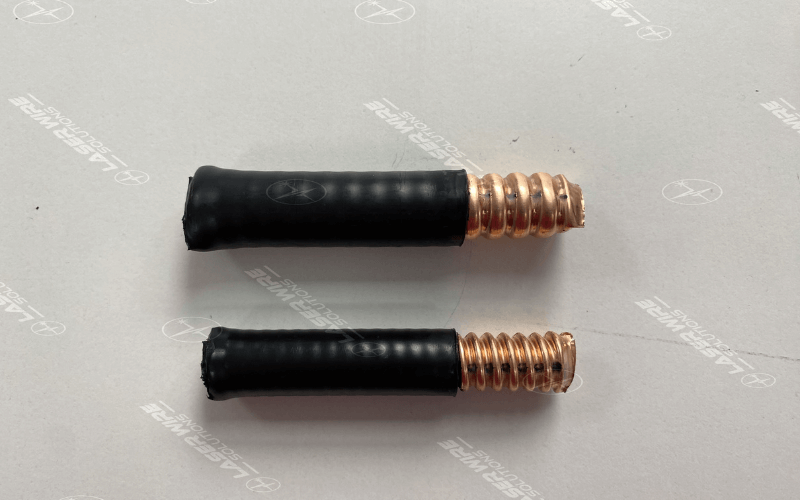

Coax cables, 13.5 and 15.8 mm in diameter

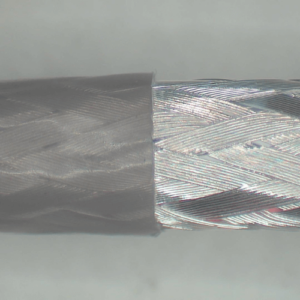

Four shielded twisted pairs, polyurethane insulation and copper conductor

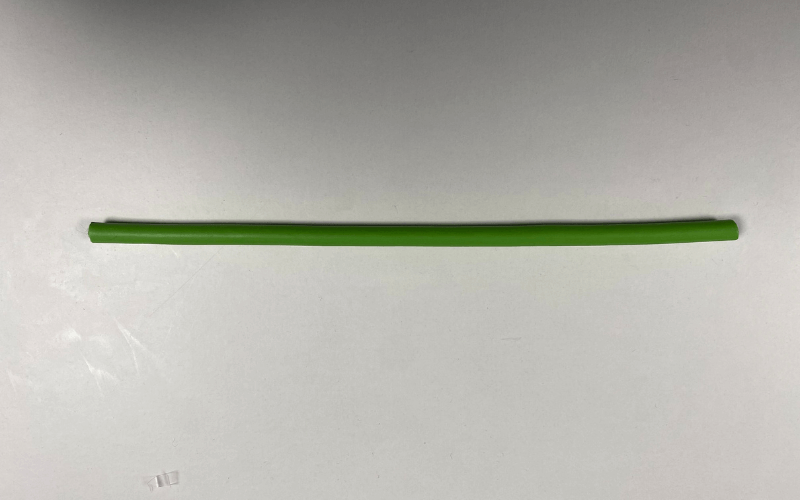

The Mercury-5 is a versatile large gauge cable processor that will make your production line smoother. The easy-to-use, recipe controlled system requires minimal training with your operators while ensuring consistent results in seconds. It can handle cables up to 6 mm diameter with ease so it is particularly suited to automotive applications such as orange coroplast cables.

Mechanical blade cable strippers often struggle with non-round cables or those with braid insulations, but laser wire strippers excel no matter the insulation type or shape of the cable. By utilizing the power of laser processing you’ll be able to achieve high quality results, without having to rely on operator capability or worn blades. It makes wire processing an easy task that can be easily completed in a matter of seconds.

Suitable Materials

Processing Capabilities

Optional Extras

More Information

FAQs

What strip patterns are possible with the Mercury-5?

The Mercury-5 is best suited to cross-cut strips via the hand insert, but slits and window cuts can also be produced on the Mercury-5.

What’s the maximum processing length?

The Mercury-5 is capable of processing lengths of up to 280 mm.

What’s the HMI?

The Mercury-5 utilizes a 4-inch color touchscreen display, the operator can start the wire stripping process via the HMI or a footswitch.

How do I order?

Complete the short form below or email sales@laserwiresolutions.com directly to discuss your requirements. We recommend sending a sample of your wire for us to process and check the suitability, we’ll then provide you with a report to ensure the results meet your requirements.

What support will I receive with this machine?

All our machines come with a 1-year warranty and you will have the option to purchase training for a small team of operators.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.