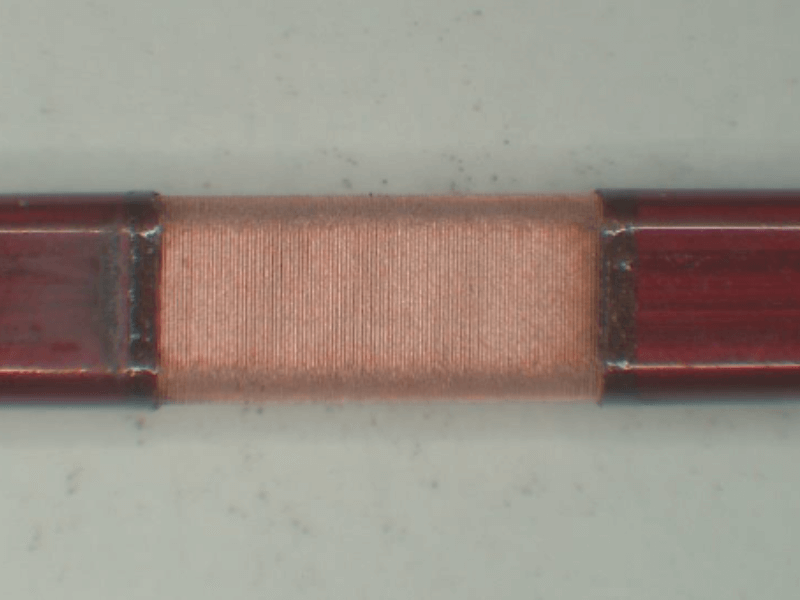

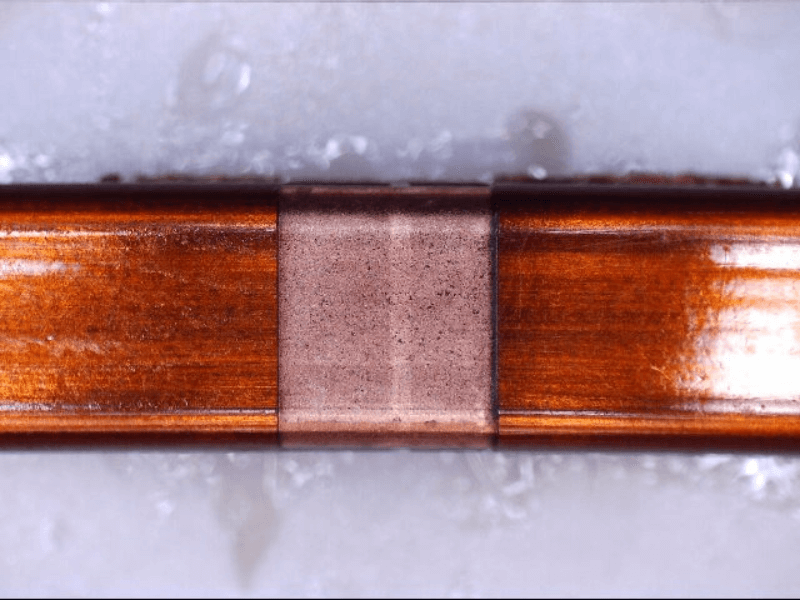

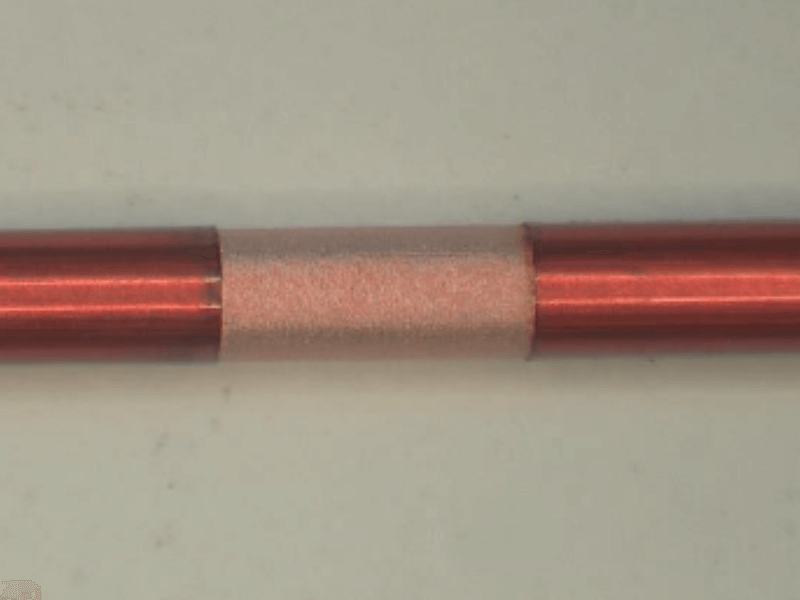

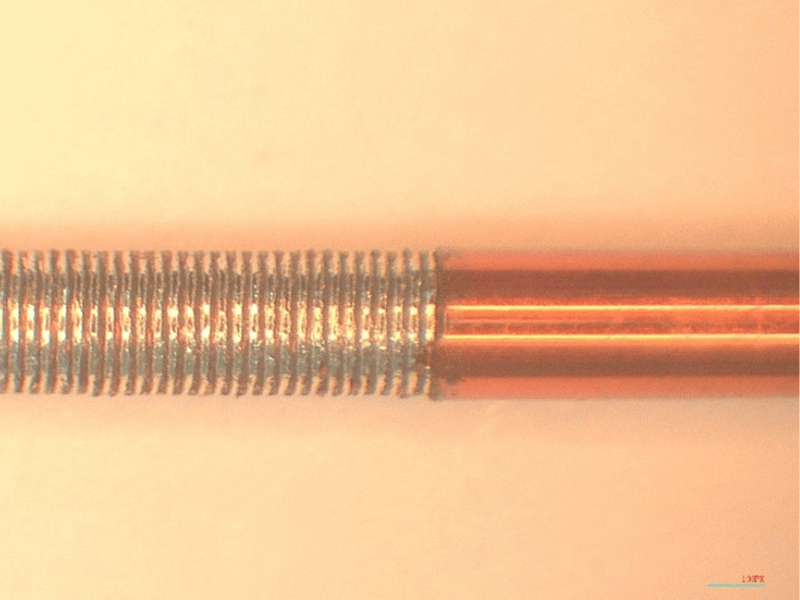

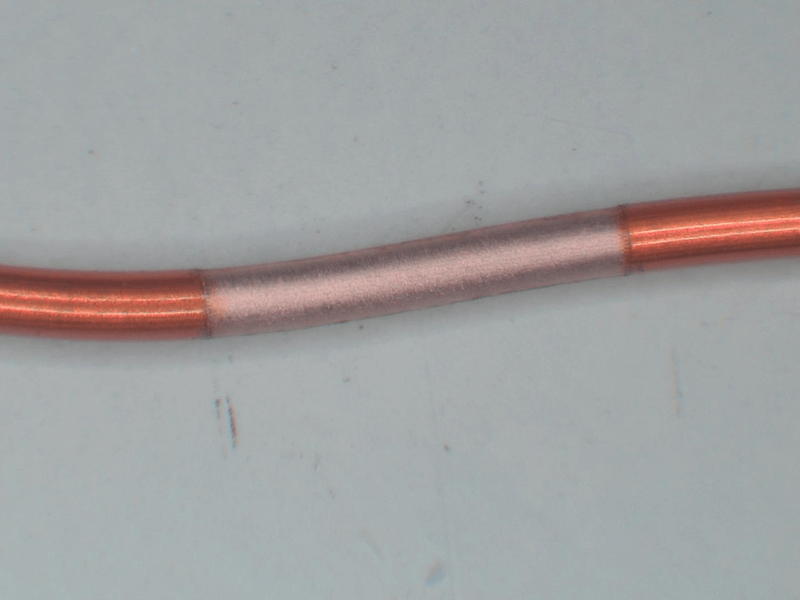

Enameled wire with a rectangular cross section, super conducting electro-magnet, requiring precision and minimal to no damage.

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the inner conductors:

The laser’s attributes allow for precise insulation ablation without affecting metal or leaving residue.

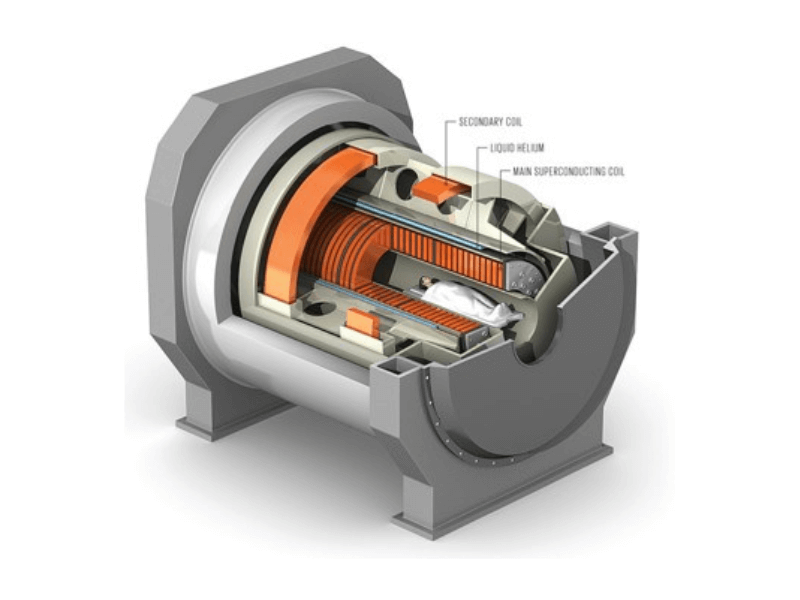

A customer in the Medical field approached us with a requirement for processing large amounts of large gauge enamel wire that would be used in MRI.

The previous process used to remove the enamel was time-consuming and carried inherent EHS and quality risks.

The Laser Wire Solutions machine allowed automation of the enamel removal process, resulting in speeding it up significantly, eliminating the EHS concerns and significantly improving product quality.

Impressed by the expertise, the skills the business showed, and how quickly they managed to process the wire, the customer proceeded with multiple orders of a customized version of the Viking-4.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.