Experience the assurance of having a dedicated ally in advanced medical devices.

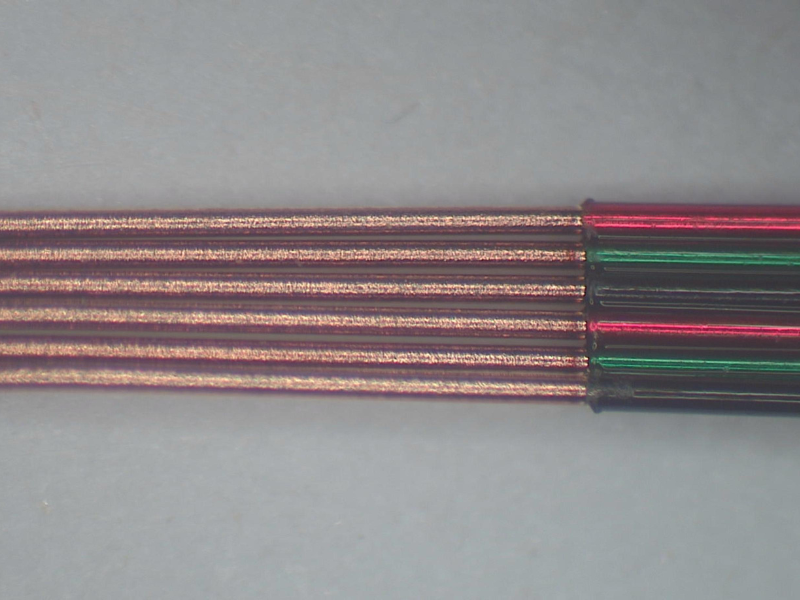

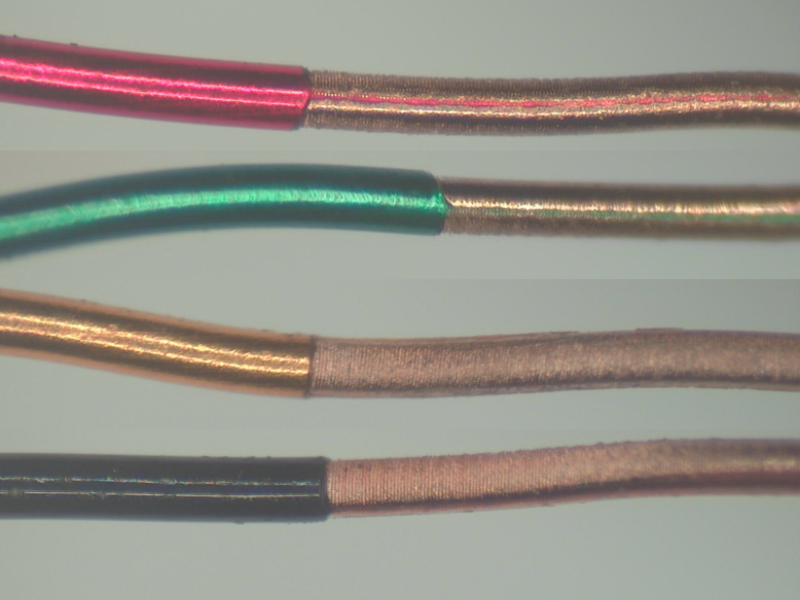

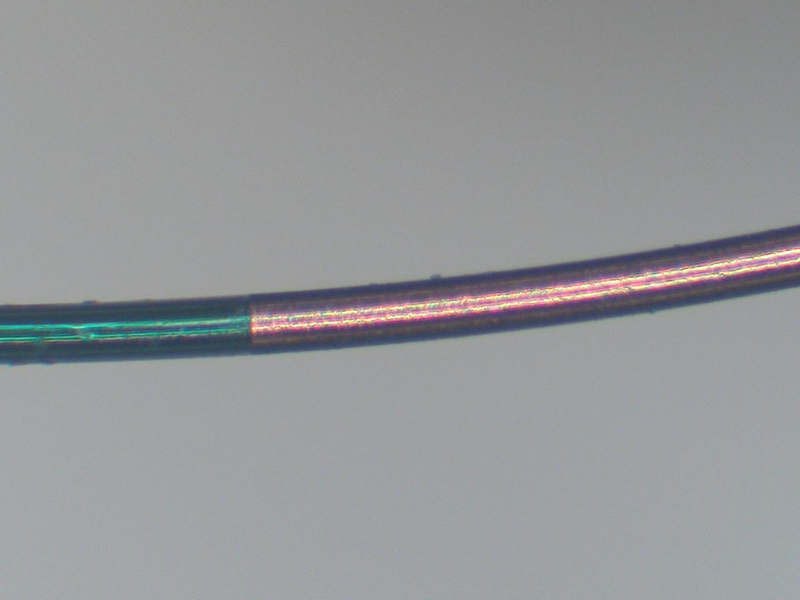

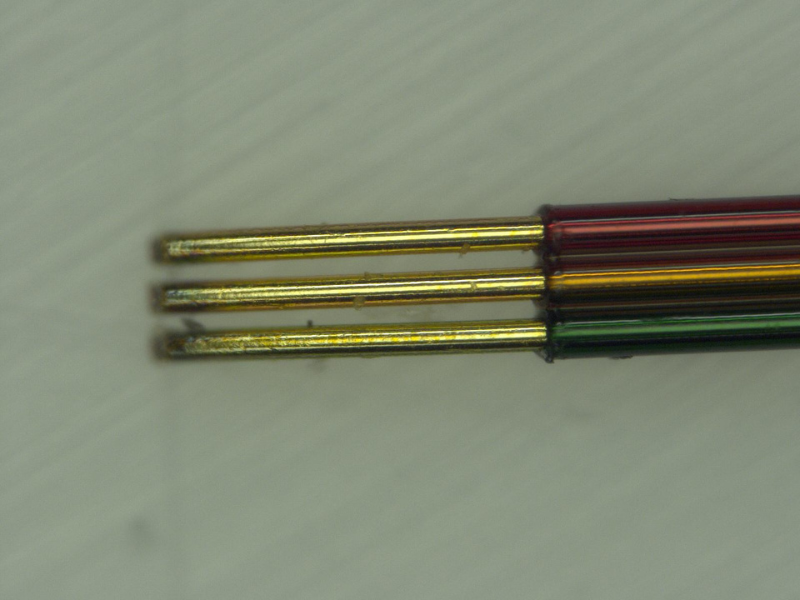

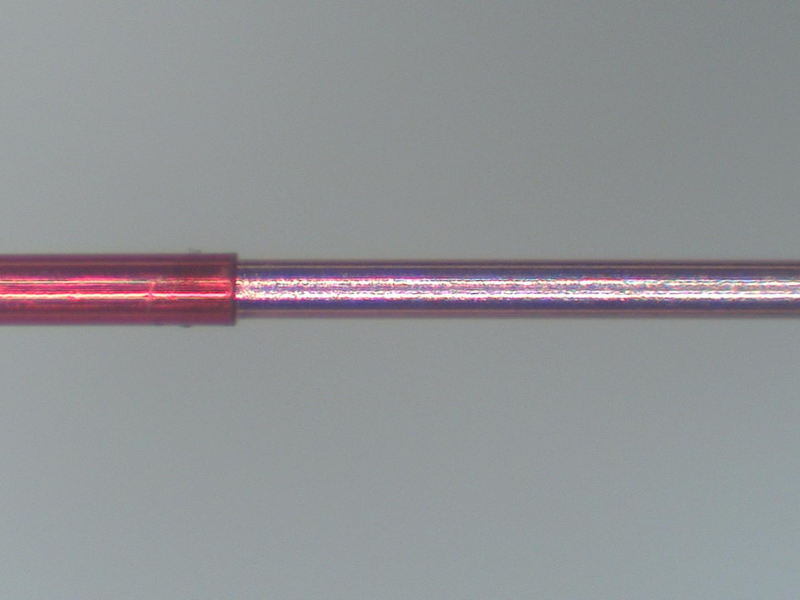

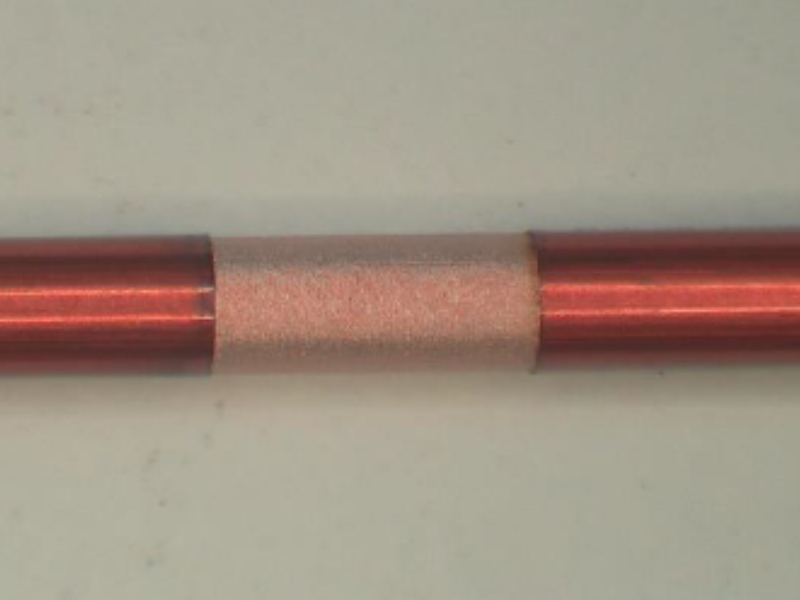

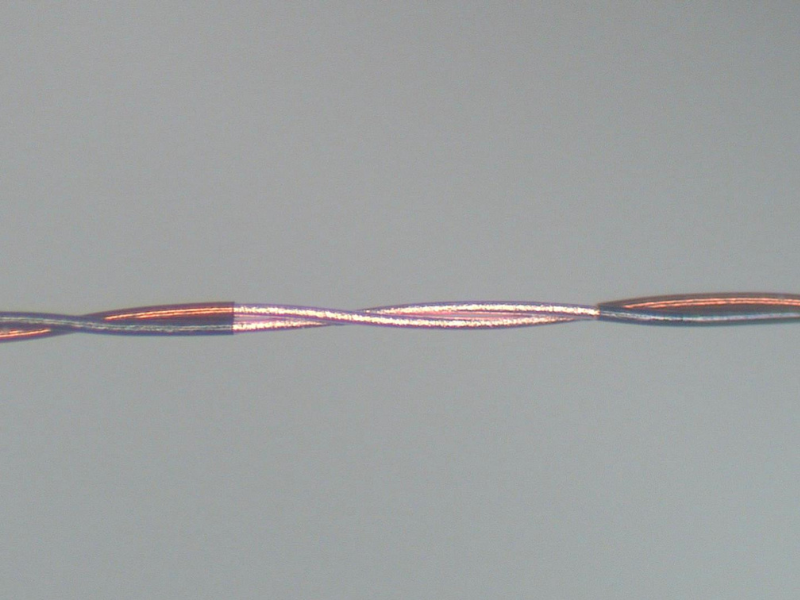

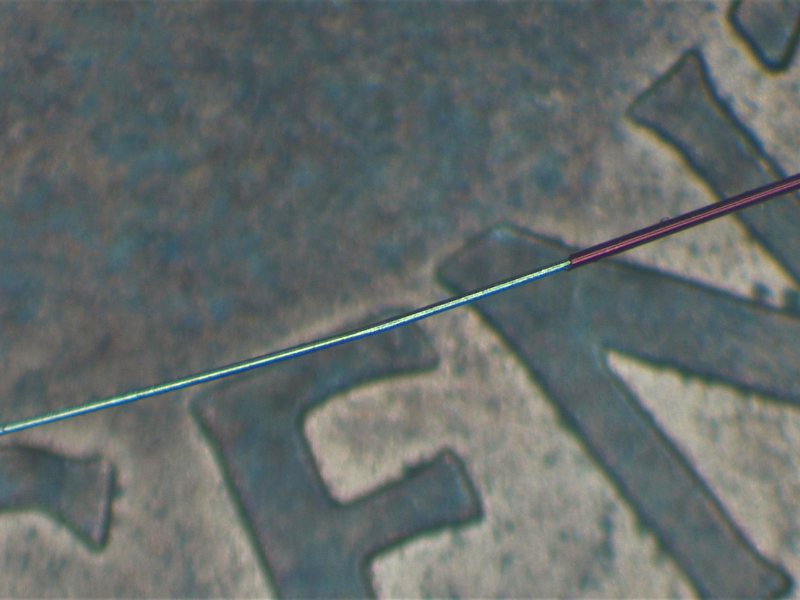

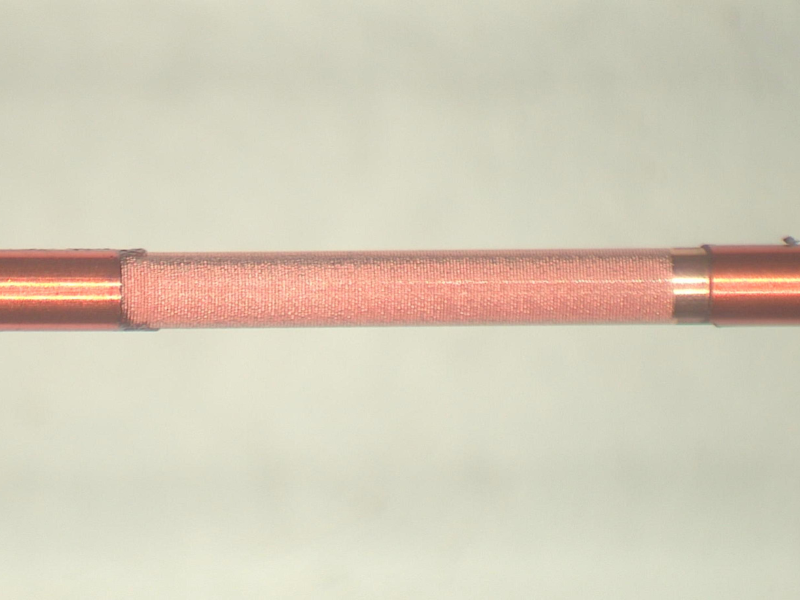

From micro fine catheter wires to MRI enamel coils, we specialize in laser wire stripping machinery that handles medical wires and cables with ease.

Suitable for OEMs specializing in cardiovascular ablation, mapping catheters, neurovascular pull wires, bone ablation.

Including:

Send us a free sample of your micro-fine wire to put our technology to the test for your application.

The right solution depends on your application, our team can advise on the most appropriate.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2024 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.