Wire Type

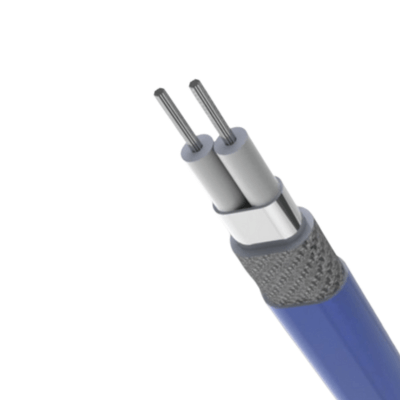

Twin-Ax

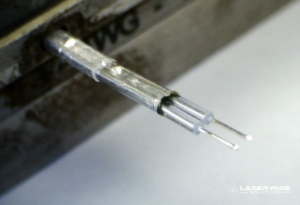

Discover how the fusion of innovation and expertise in laser wire stripping technology empowers TwinAx and InfiniBand cables, harnessing their distinct advantages in bandwidth, latency, and reliability, to emerge as the bedrock of modern data centers and computational infrastructures.

Achieve precision and reliability, epitomized by the precision of laser wire stripping processes, that define the future of high-speed data transmission.

Where the connectivity between servers and storage devices is the lifeblood of data centers and high-performance computing environments, our laser wire stripping ensures that TwinAx or Infiniband cables maintain their pristine state.

Market Application

- Data Centres

- high-speed server-to-server and server-to-switch connections

- High Performance Computing

- rapid data transfers and minimal latency

- Medical

- rapid transfer of large medical data sets

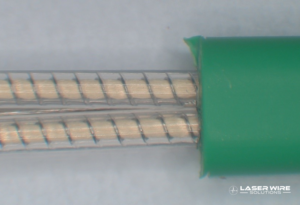

The Wires

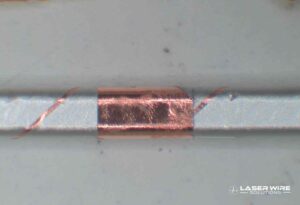

- Single drain wire underneath foil

- the foil conductive layer contacting the drain.

- Two drain wires on the outside of the foil,

- the conductive foil surface facing out.

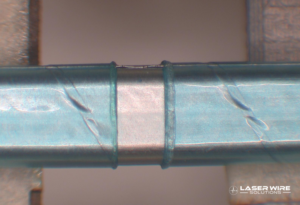

Traditional Technology Drawbacks

- Manual input required to strip the foil

- Residue left behind, leading to poor data transfer

- Blades get easily worn, needing to be replaced often

- Conductors need to be bent during the process

- Inaccurate spacing between the cut foil and the cut dielectric

- Unable to automate the process

Our Solution

Mercury 4E

- Easy configuration for end-strips, window cuts, slits or even area vaporization

- Strips wires and shielded cable ranging from 0.025 mm to 6 mm outer diameter

- Suitable for bonded and shielded materials

- Can be used as a standalone machine or in-line

Why Choose the Mercury 4E?

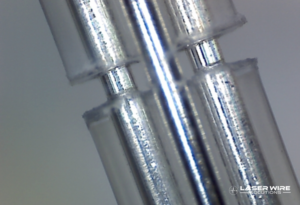

- Selective removal of the layers

- Precise geometry by software control

- Highly repeatable

- High yield process

Not looking to make a capital investment?

Utilize our Contract Manufacturing suite for pre-stripped wire to be delivered direct to your production line ready for use.

Test Our Machines for Your Application

Send us a free sample of your infiniband cables to put our technology to the test for your application.