Fine Enamel Wires

Typically, electrical wires for catheters and other medical devices are stripped using chemical or manual methods, meaning you’re relying on operator capability and training, which results in poor and inconsistent results.

Lasers ensure a clean and consistent strip each time. Find out about our medical device wire stripping solutions below.

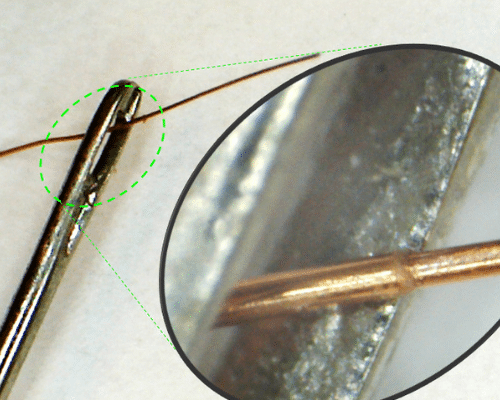

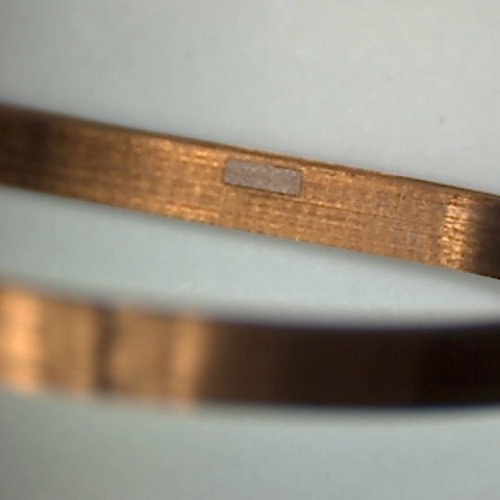

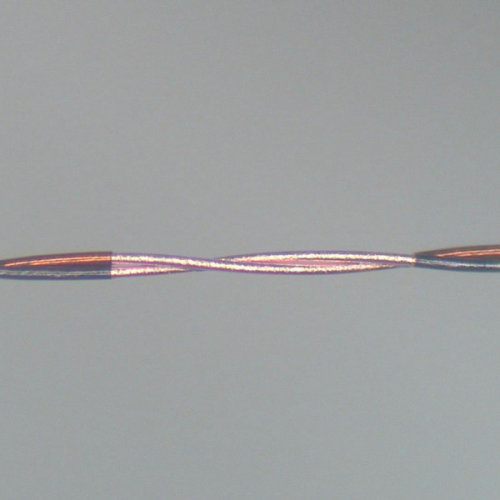

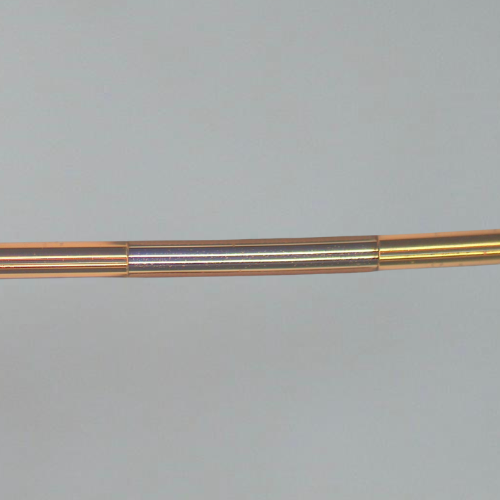

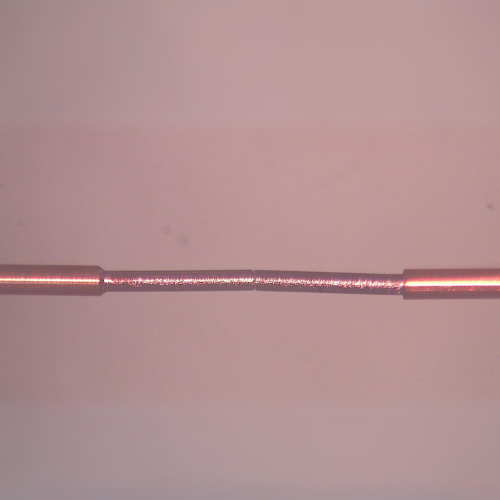

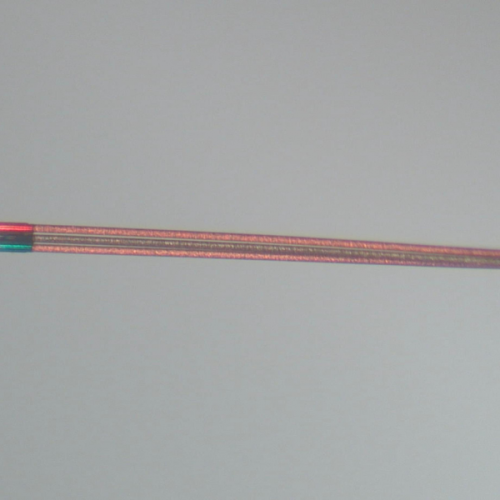

Fine Enamel Wires

These wires have been stripped using Laser Wire Solutions technology

Our Solutions

The latest advances in electrophysiology require packing ever more sensors and wires into ever smaller packages. Polyimide (also called enamel) type insulations offer the highest density of interconnects due to the thin, tough insulation.

Wire gauges of 42 AWG to 50 AWG are now commonplace, with applications for wires smaller than 50 AWG now appearing. These wires are tough to strip.

There are only 2 real options: mechanically scraping or hot caustic dipping. The former presents a challenge for small gauges due to damage of the conductor and the latter is not preferred due to safety issues and residues.

Even standard laser stripping with carbon dioxide lasers is not a solution as the long wavelength of the light means that a microscopic residue is left which cannot be soldered to. Our solutions offer a powerful yet gentle approach that ensures the wires remain suitable for use in medical devices.