Wire Type

Fiberglass

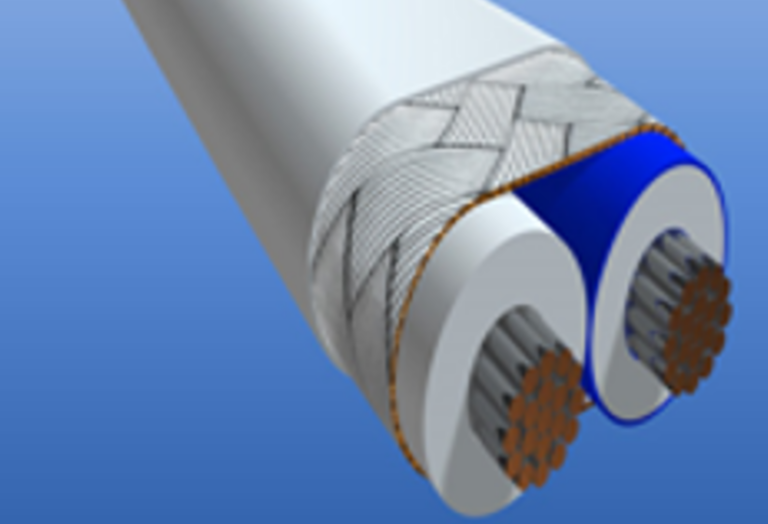

Fiberglass insulations can provide excellent insulation for wires and cables with automotive and electronic applications due to being highly flexible, chemical-resistant, and abrasion-resistant. But these properties can make it a tough material to process when making connections.

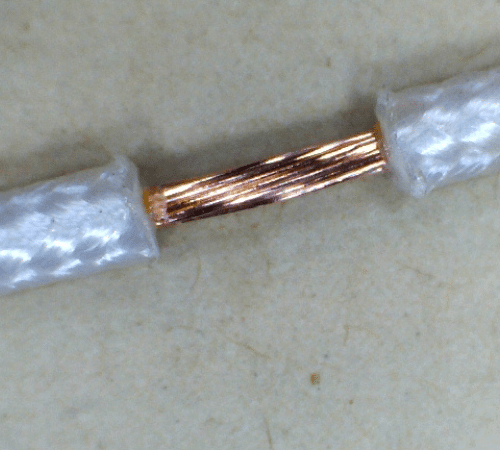

Many methods struggle to process fiberglass insulation without causing any damage to the underlying wires and cables, but lasers can remove the insulation safely without any damage to these.

Market Application

- Aerospace

- High temperature environments

- Automotive

- Environments handling potentially corrosive materials (chemicals/abrasives/moisture)

- Military and Defense

- Environments experiencing extreme conditions, rapid temperature changes

Traditional Technology Drawbacks

- Mechanical stripper/Exacto knife

- Worn blades

- No process control

- Wire nicks/scrapes

- Low yield (poor weld strength)

Our Solutions

Mercury 4

- Removing jackets from shielded multiconductor cables

- Removing jackets and dialetrics from high performance microwave cables

- Fast processing time

- Interchangeable door fixture

Mercury 5

- Automatic cable centralizer to ensure repeatability

- Nick-free stripping

- Ideal for large gauge wires

- Up to 280mm strip length

Mercury 6

- Ideal for large gauge wires

- Up to 200mm strip length

- Cross cut, window cut, slit and more

- Automatic cable centralizer to ensure repeatability

The right configuration depends on your requirements. Contact our team to find out which solution suits your application.

Why Choose Laser Wire Stripping?

- Non-Contact

- No wear parts

- Conductor strands are preserved

- Self terminating process

Not looking to make a capital investment?

Utilize our Contract Manufacturing suite for pre-stripped wire to be delivered direct to your production line ready for use.

Test Our Machines for Your Application

Send us a free sample of your wires and cables with tough insulations to put our technology to the test for your application.