Designed with the operator in mind, the Mercury-4 has been optimized to meet your production needs.

The Mercury-4 laser wire stripping solution has the capability to strips single conductor, coax and ribbons of all insulations with minimal effort.

With dual axis motion it handles all strip types: cross-cut, windows and area ablation; and any shapes: curves and hatched areas, not just straight lines, with complete ease for the operator.

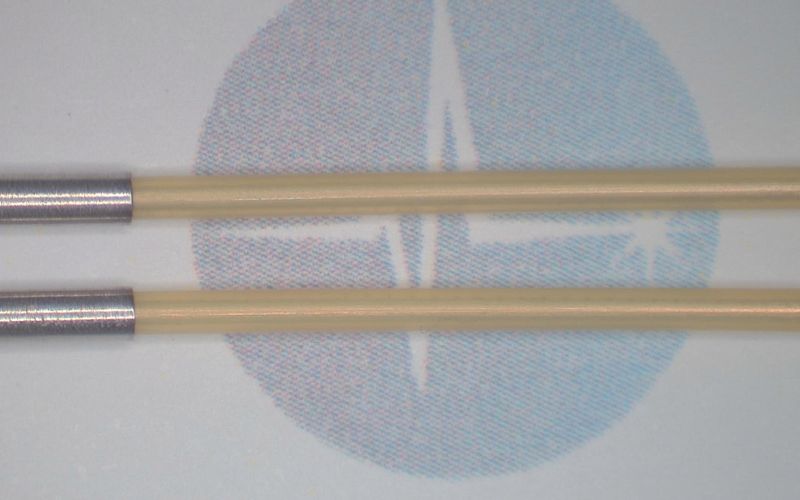

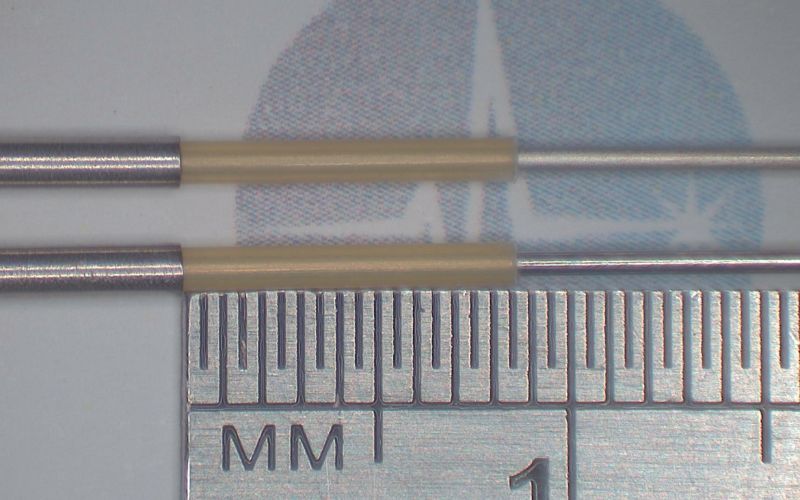

Teflon coated stranded wire with 1.2mm

Multicore with outer diameter of 4mm, LDPE insulation with strip length of 100mm

Surgical apparatus made of metal and plastic

The Mercury-4 is a versatile machine that will suit a wide variety of applications. The easy-to-use, recipe controlled system requires minimal training with your operators while ensuring consistent results in a matter of seconds. Depending on the chosen fixture, it can handle cables up to 5 mm diameter with ease and can process almost any insulation type.

Mechanical blade cable strippers often struggle with non-round cables or those with braid insulations, and chemical dips can be a health and safety nightmare, but laser wire strippers excel no matter the insulation type or shape of the cable while ensuring the safety of operators. Not to mention the results are consistent regardless of operator capability. By utilizing the power of laser processing you’ll be able to achieve high quality results, without having to rely on operator capability or worn blades. It makes wire processing an easy task that can be easily completed in a matter of seconds.

While the Mercury-4 can process most wire and cable materials, we recommend producing a small sample of wire for testing to ensure processing suitability.

Suitable Materials

Processing Capabilities

Optional Extras

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.