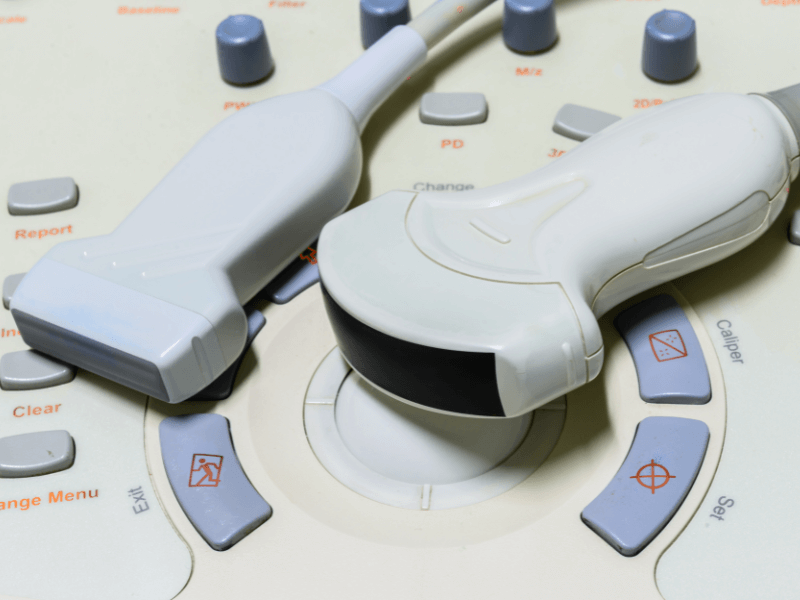

Usually found in medical device cabling where space and weight are limited.

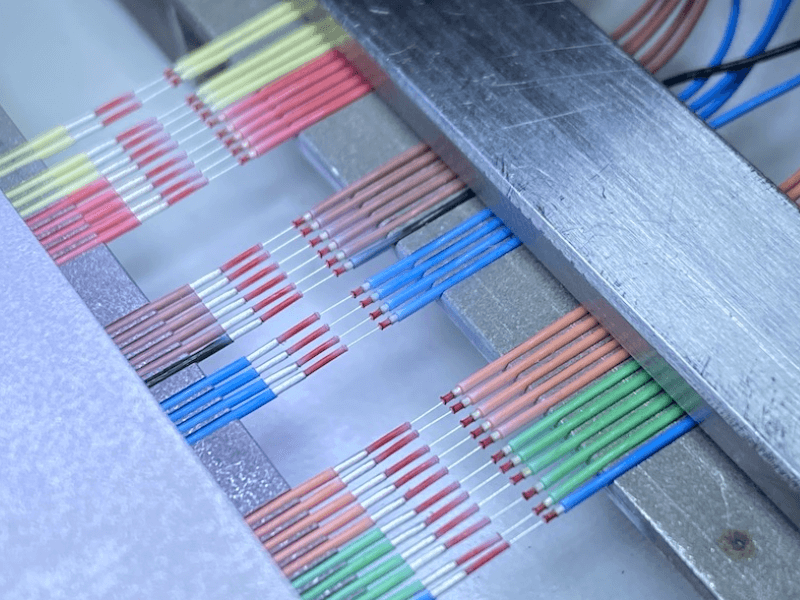

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the inner conductors:

The laser’s attributes allow for precise insulation ablation without affecting metal or leaving residue.

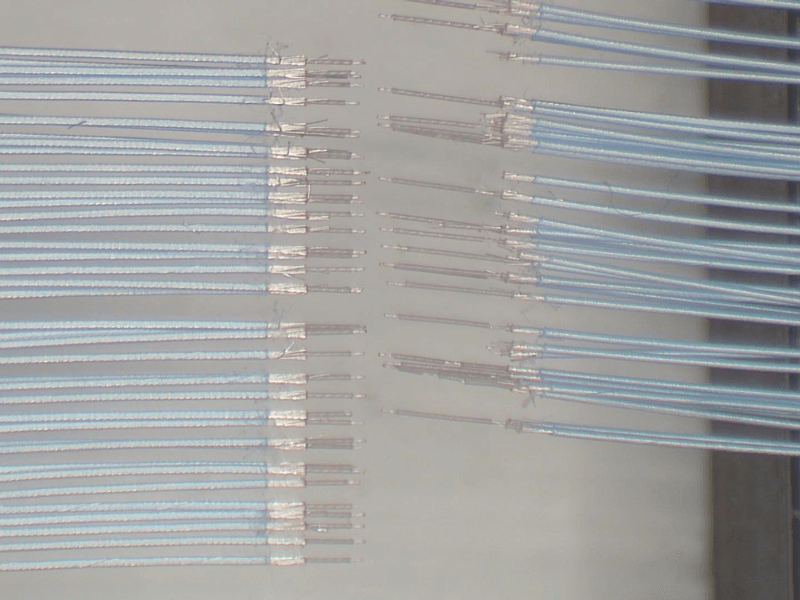

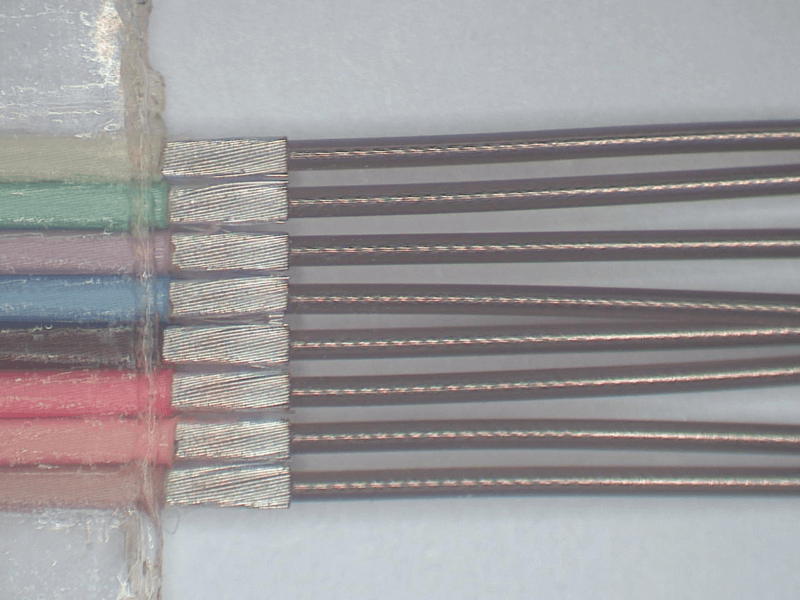

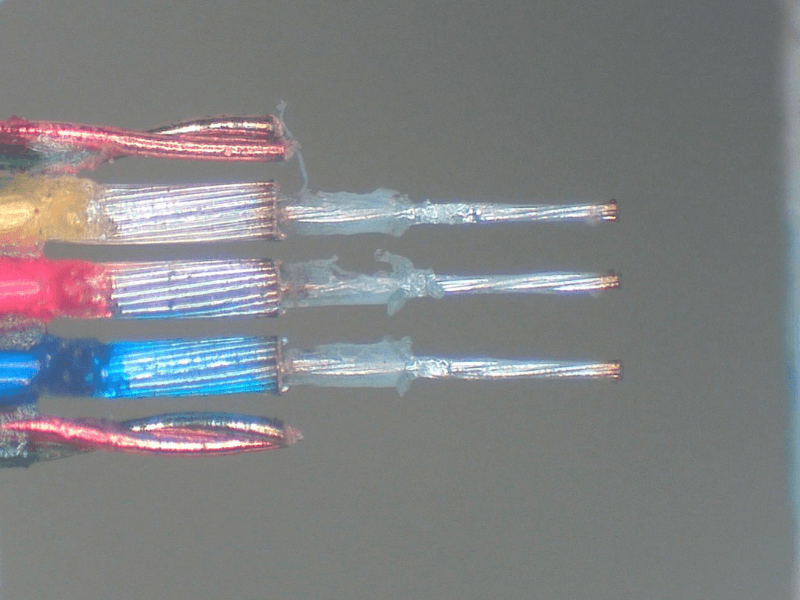

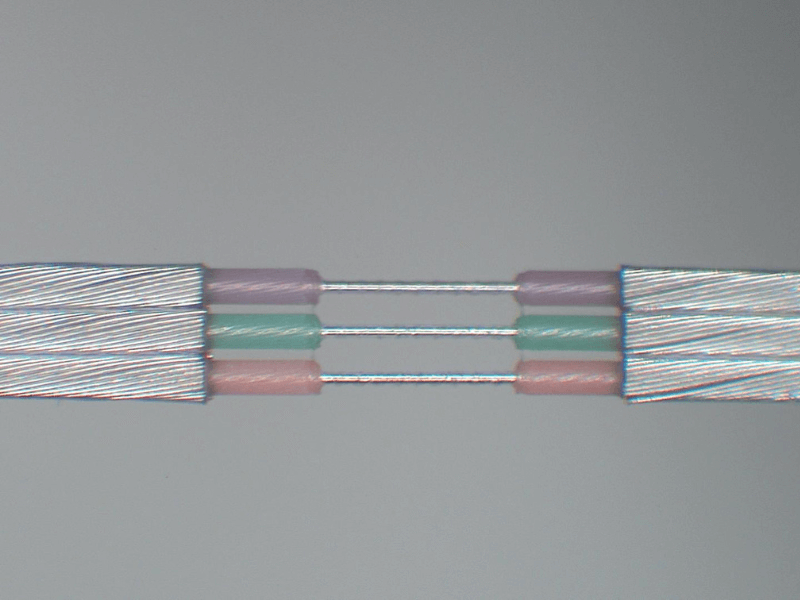

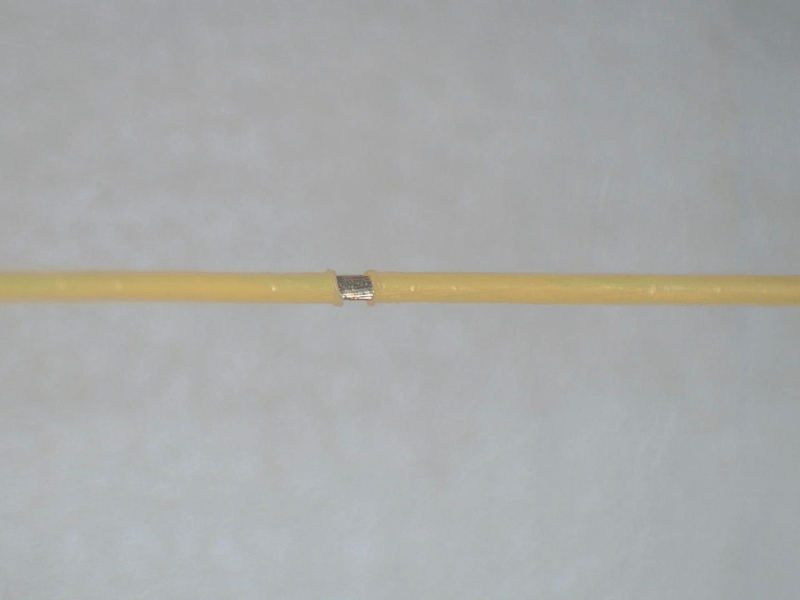

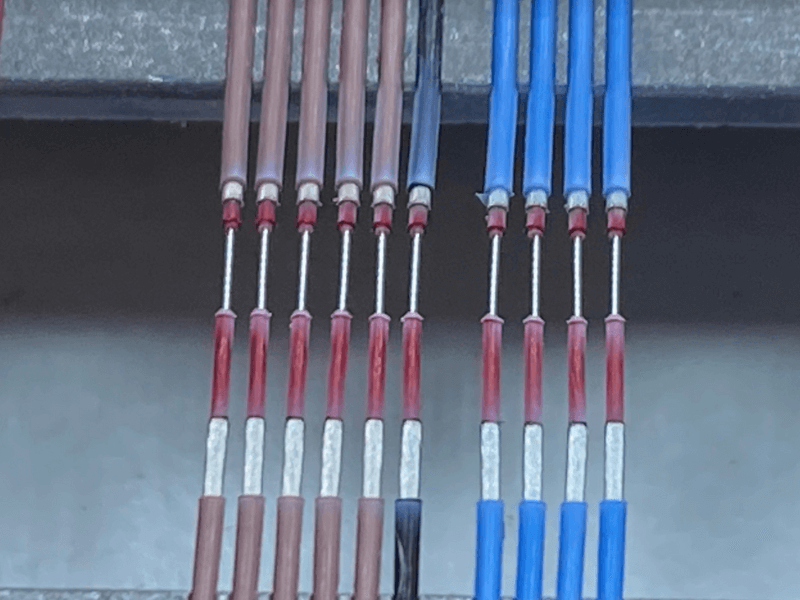

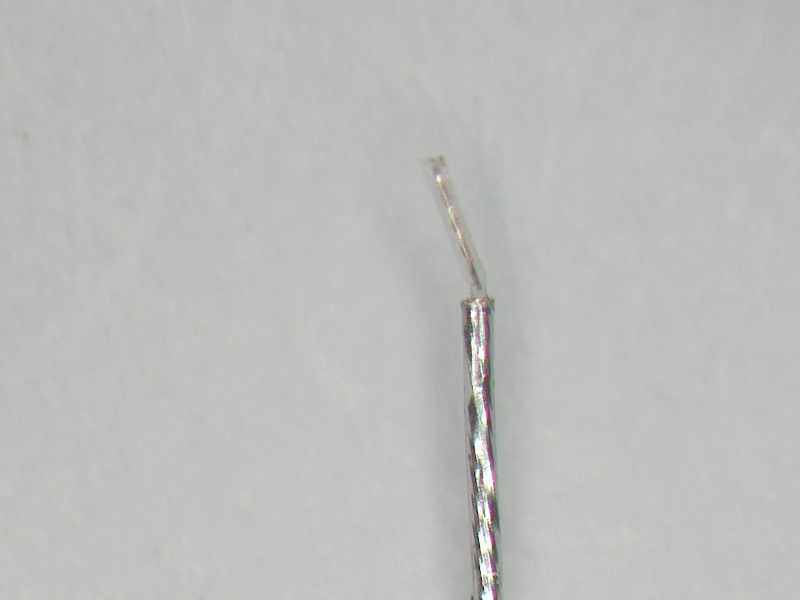

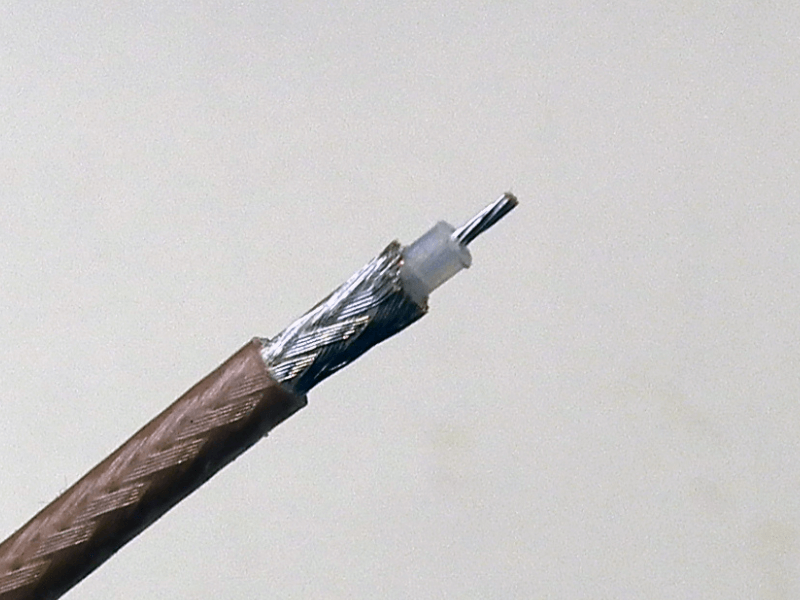

A customer provided samples of Niobium Titanium and Cupronickel wires with PTFE dielectric for processing. They were currently facing difficulty achieving the results they required with their blades because of the tight tolerances. The task required a precise 2mm strip of the outer conductor and dielectric to be removed in order to reveal the inner conductor.

The processing was carried out using our specialized micro-coax centre machine. A key aspect of this project was the stringent control over the geometry of the samples, which were maintained within a processing tolerance of +/- 0.1mm.

This case exemplifies our ability to handle complex materials and deliver high-precision results in laser processing applications.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.