Specialized coils or windings used in critical applications, including sensitive electronic equipment, medical devices, and aerospace systems.

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the inner conductors:

The laser’s attributes allow for precise insulation ablation without affecting metal or leaving residue.

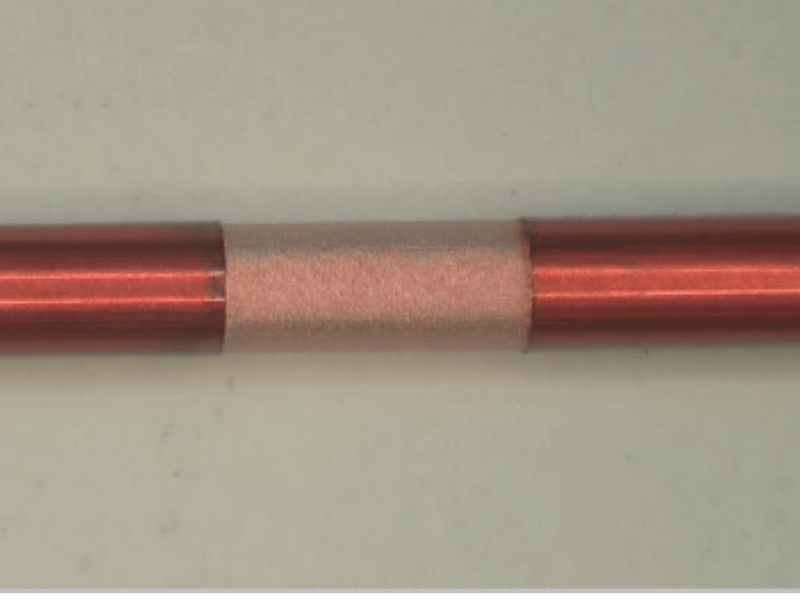

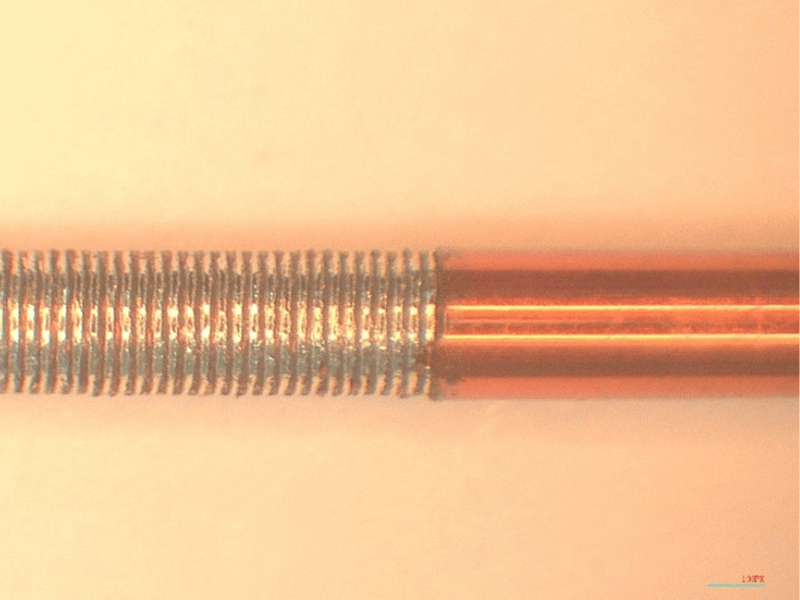

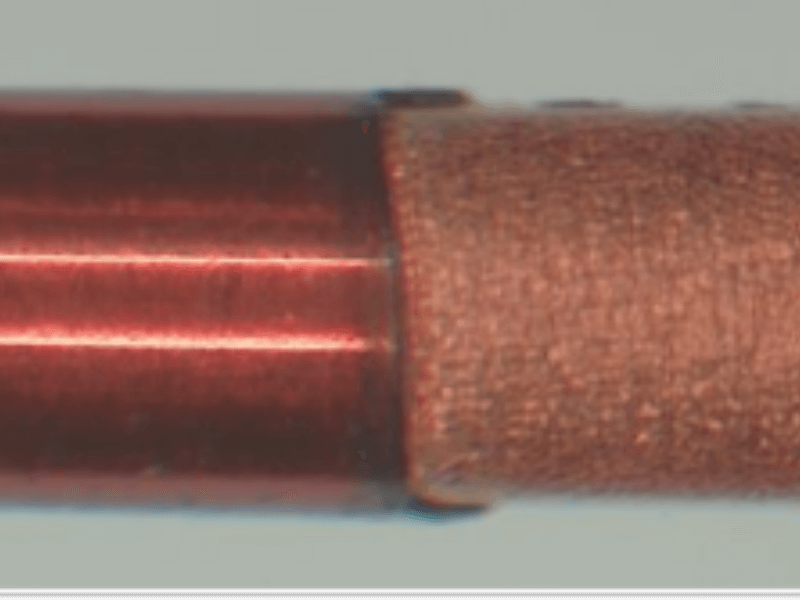

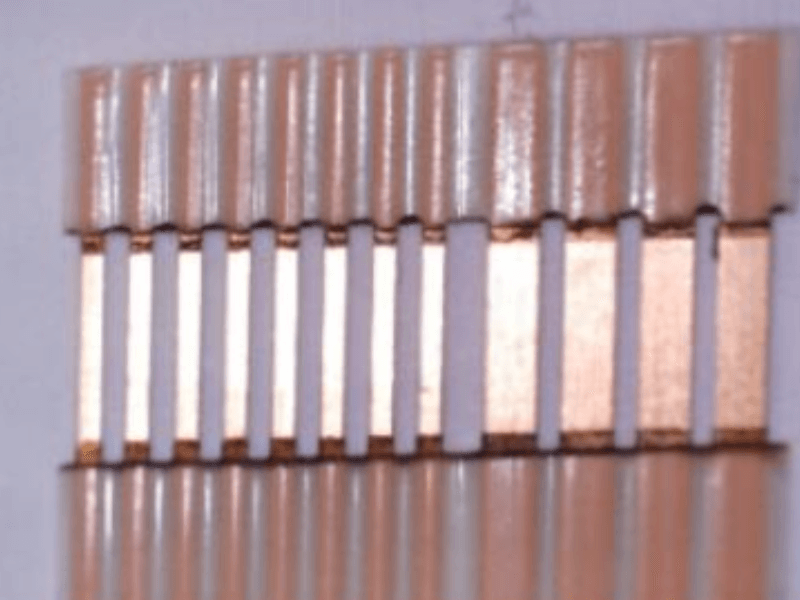

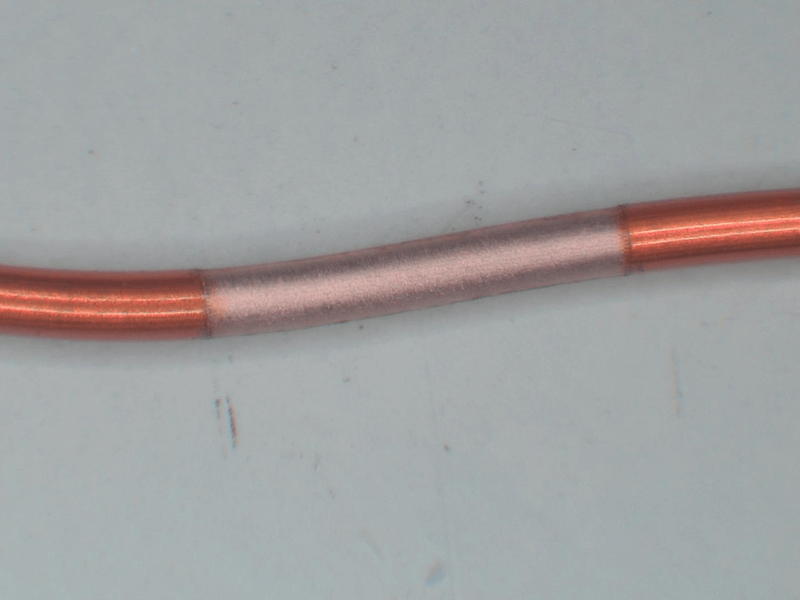

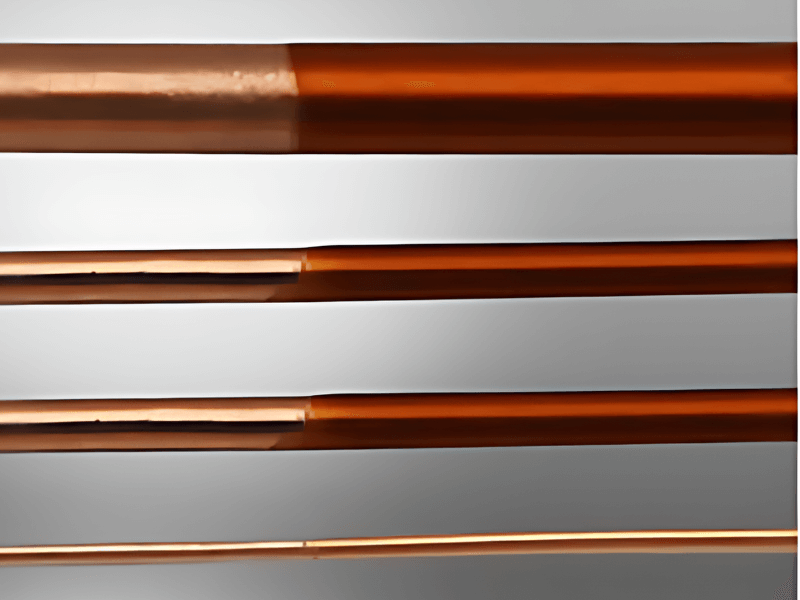

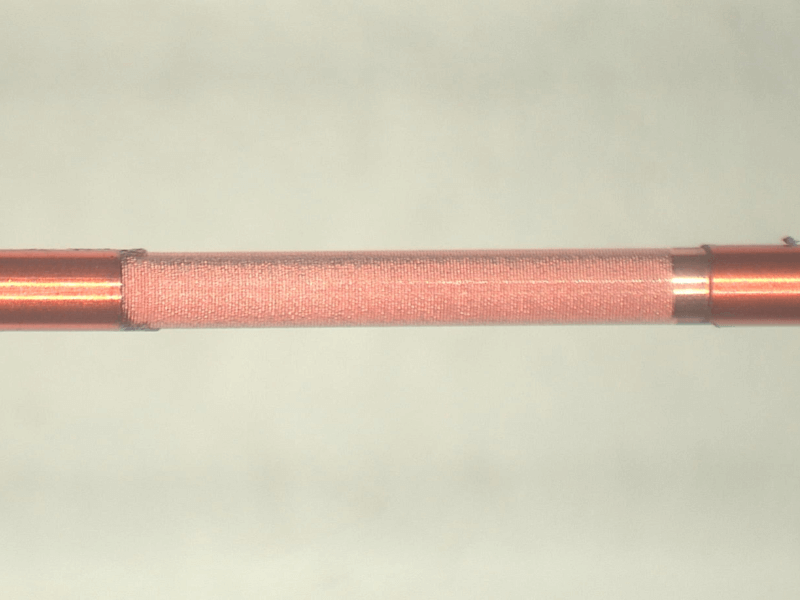

A global automotive supplier approached our partner searching for a solution to process their enamel coil, they required a 6mm strip on uncoiled wire.

Our partner suggested laser technology was the most suitable option to provide a clean strip with no residue. The customer submitted a sample of wire for proof of concept and the Laser Wire Solutions team were quick to identify the Gemini-4 as the best solution for this wire type.

They produced a 6x3mm hatch strip on a portion of the wire with a 12 second cycle time, having optimised it to ensure the highest level of quality for the customer. The team also conducted a solderability test so the customer could see the effectiveness of laser wire stripping.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2024 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd CF37 5YR.

How can we improve your experience?

Please take our short survey here.

Discover the capabilities of our machines with your application before you buy.