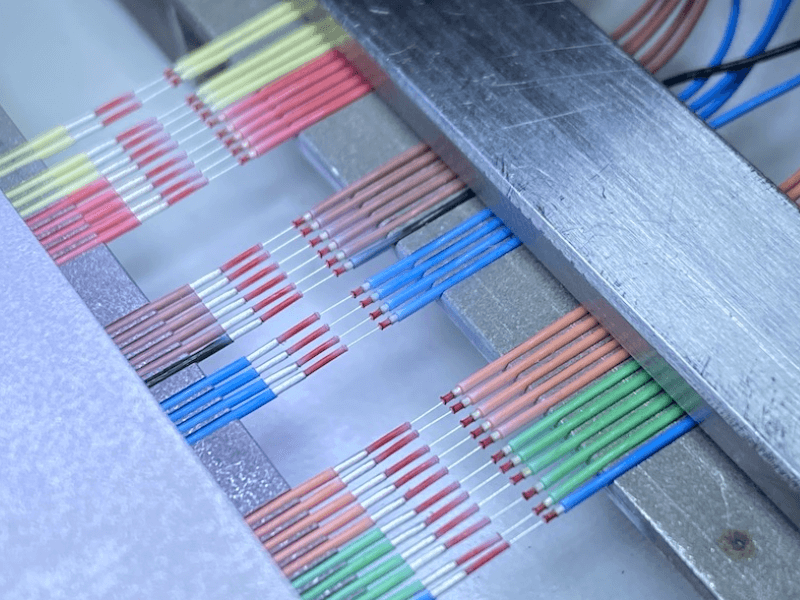

Data center twin-ax cables – super accurate dielectric and foil cuts required with no residue for optimal connections.

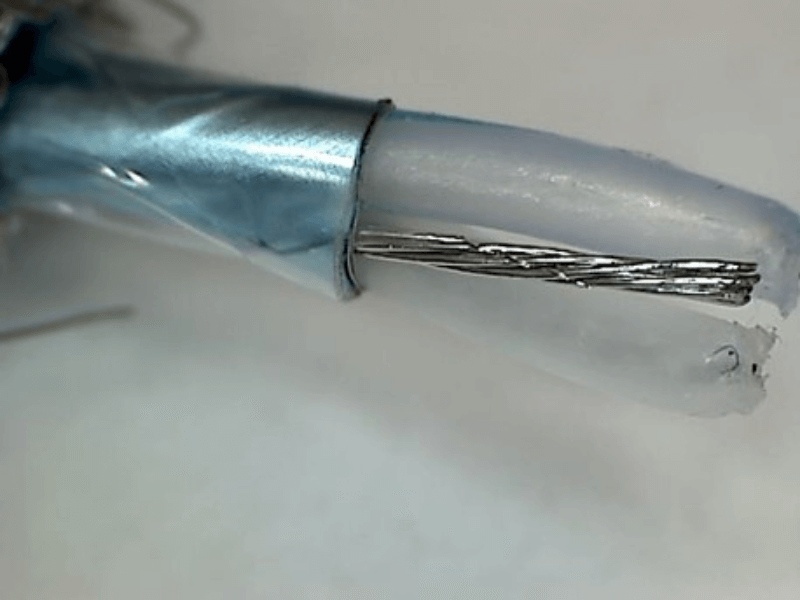

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the inner conductors:

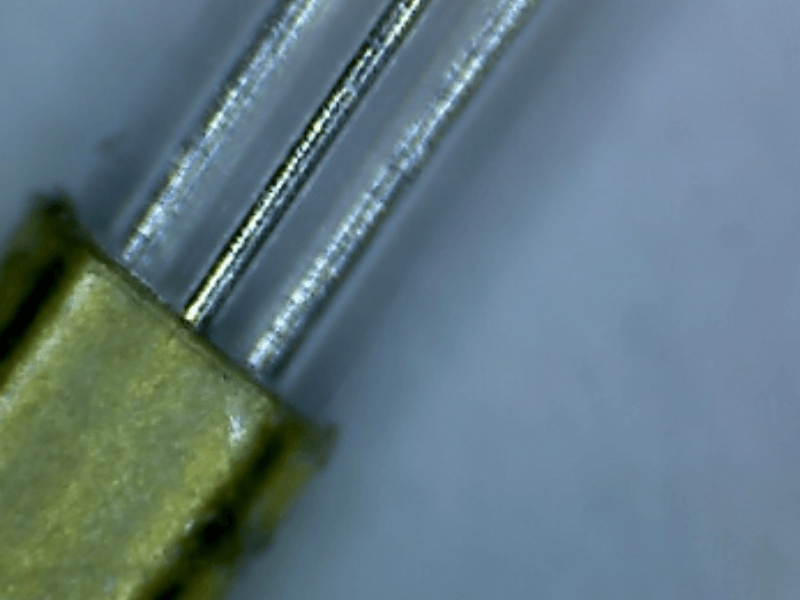

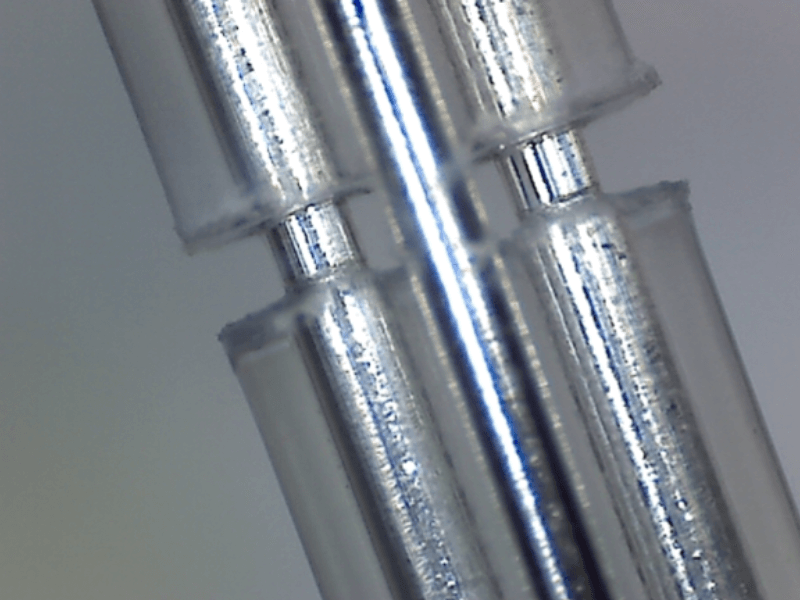

The laser’s attributes allow for precise insulation ablation without affecting metal or leaving residue.

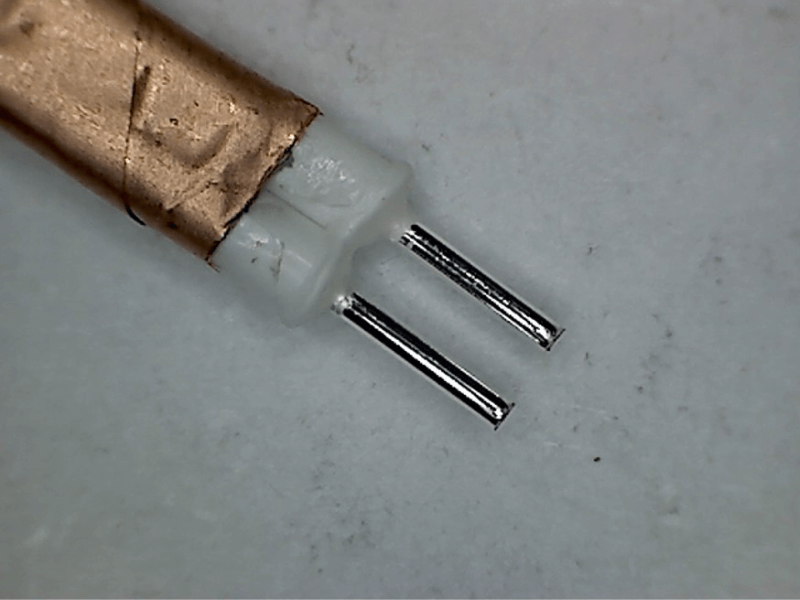

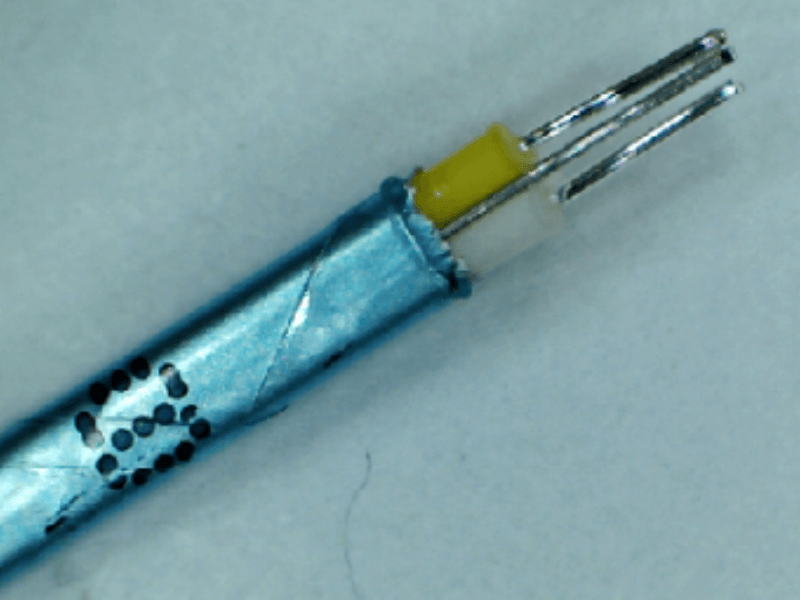

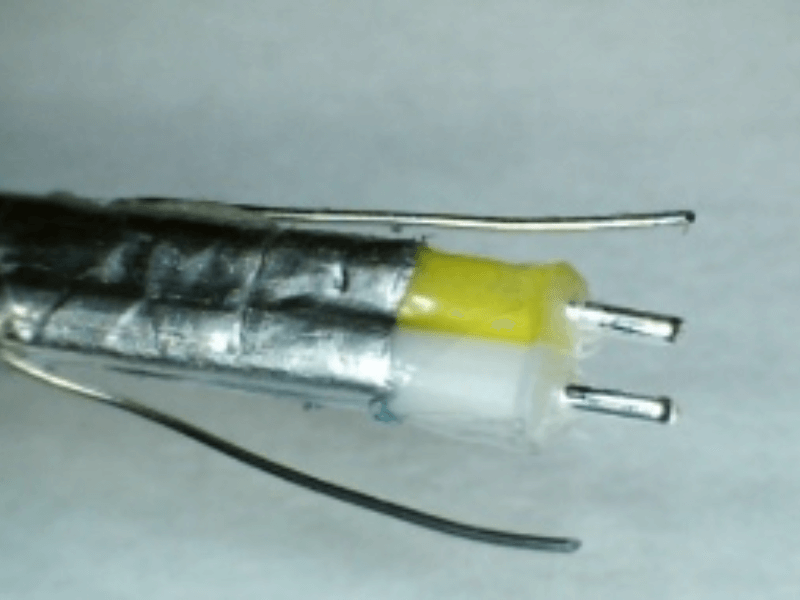

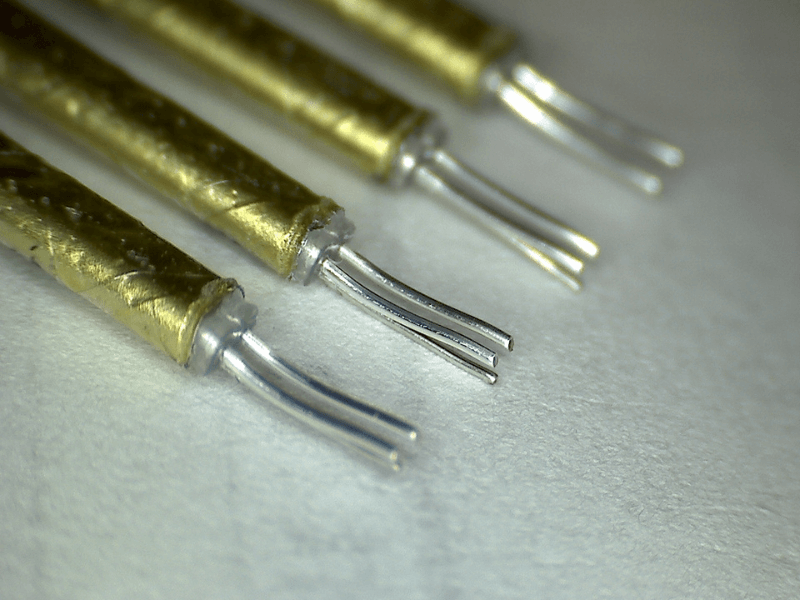

A customer in the Data industry submitted 32AWG shielded parallel pair wire samples with Mylar and foil insulation for processing using our laser technology. The customer’s request was to remove the outer jacket, foil, and dielectric from the provided samples to expose the inner conductors.

The wires were processed swiftly and efficiently on both the Mercury 4 and Odyssey 4 laser systems, with the process settings being based on a basic optimization of parameters.

The Mercury 4 laser system was highly recommended for the removal of the dielectric, as it ensured the complete preservation of the inner conductors. The process took 15 seconds in total to precisely strip the insulation.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.