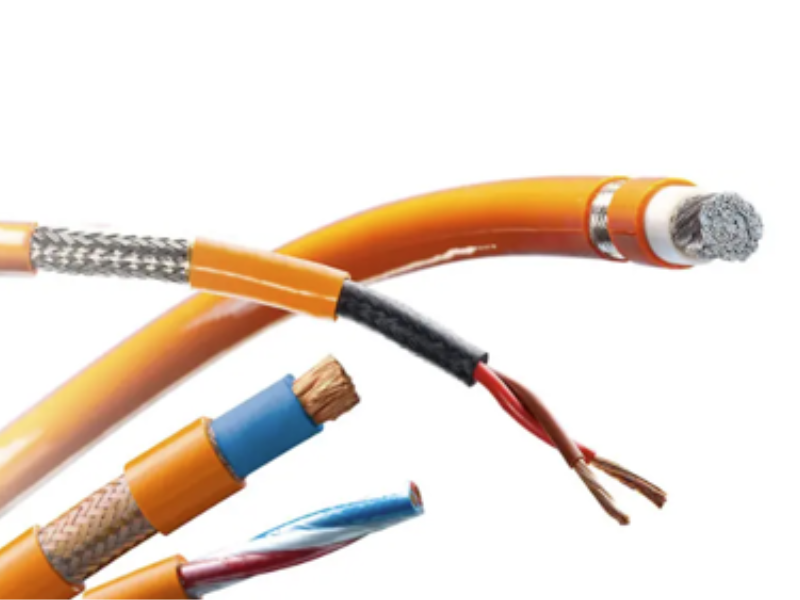

Non-round cables, shielded twisted pairs, fibre glass insulation, bonded insulation, thin insulation, foil shields where blades do a poor job.

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the inner conductors:

The laser’s attributes allow for precise insulation ablation without affecting metal or leaving residue.

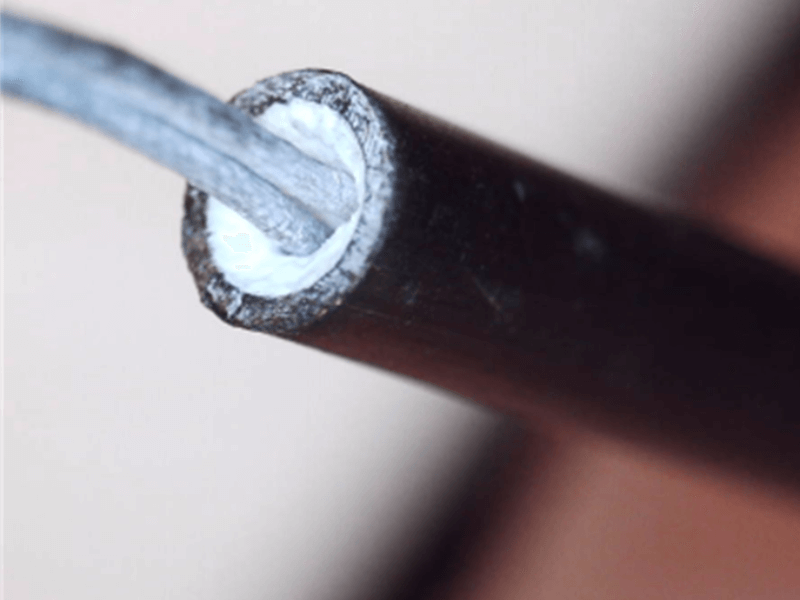

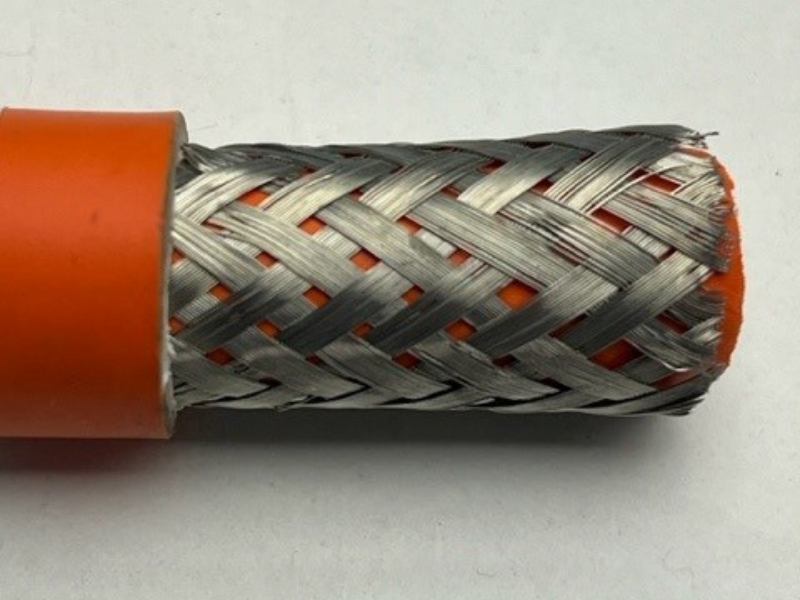

A leading electric vehicle manufacturer was struggling with the mechanical processing of foil under coroplast insulation, which often resulted in cut strands in the aluminium inner layer because the cable was not typically rounded.

They approached Laser Wire Solutions with a sample of their 20mm outer diameter shielded coroflex cables, and specified that they needed to reduce the amount of waste they were currently producing with their mechanical method.

Once the Laser Wire Solutions applications team received the samples from the customer, they quickly identified that the Mercury-6 would be the ideal solution. The Mercury 6, a machine specifically designed for this type of cable, was used to process the material. The machine successfully performed a ring cut and slit on both the outer and inner jackets in approximately 18 seconds each, effectively overcoming the manufacturer’s challenge and paving the way for more efficient production processes.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2024 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.