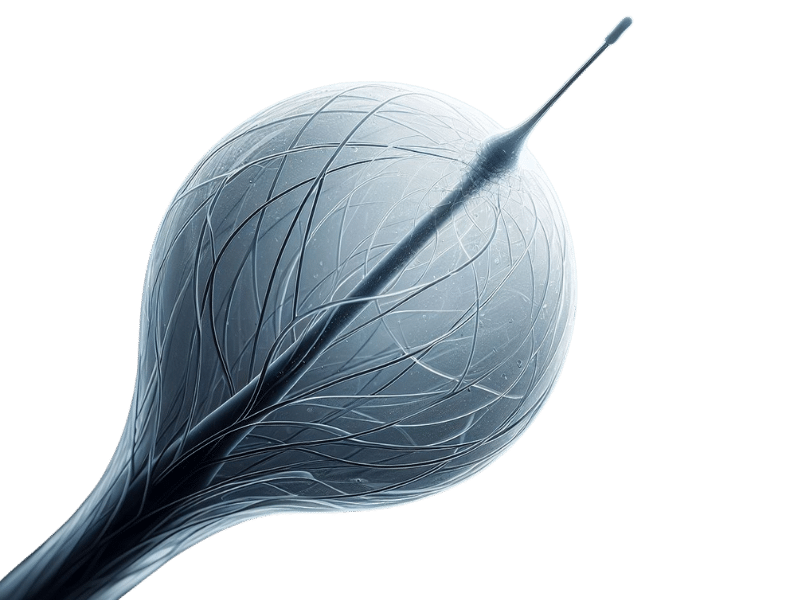

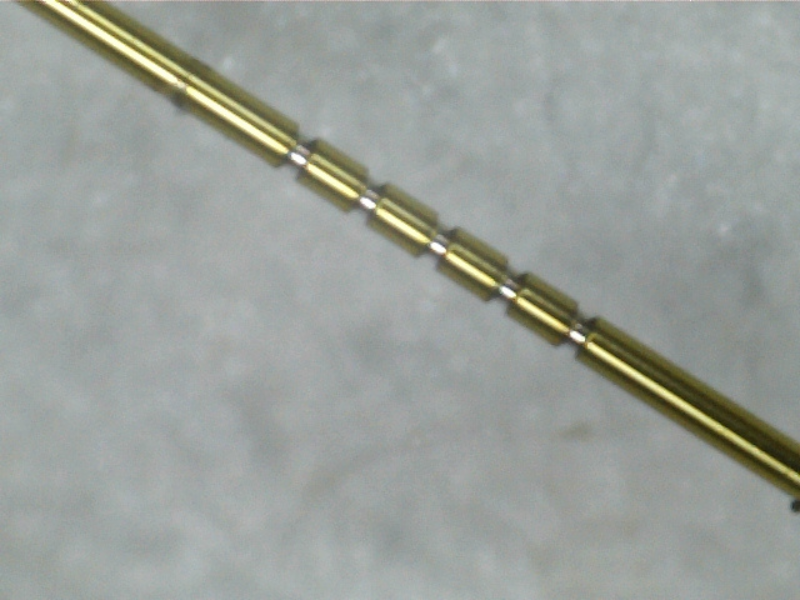

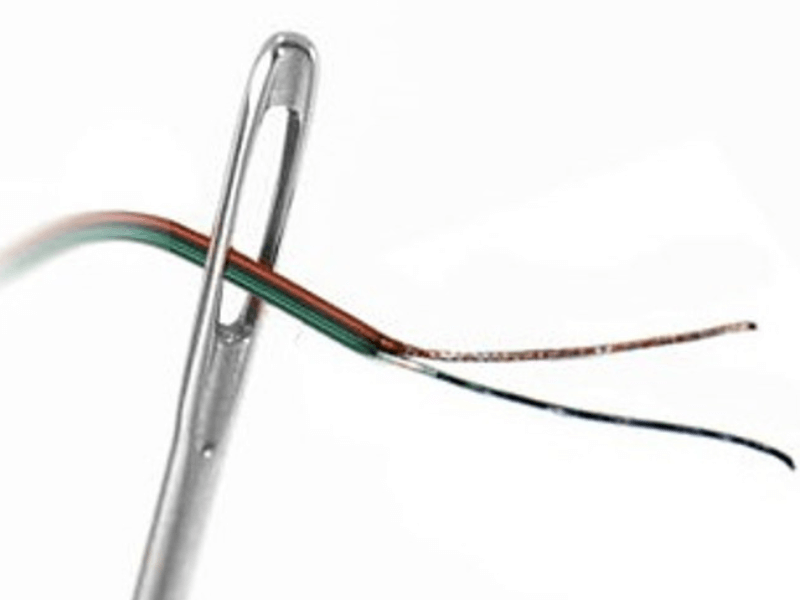

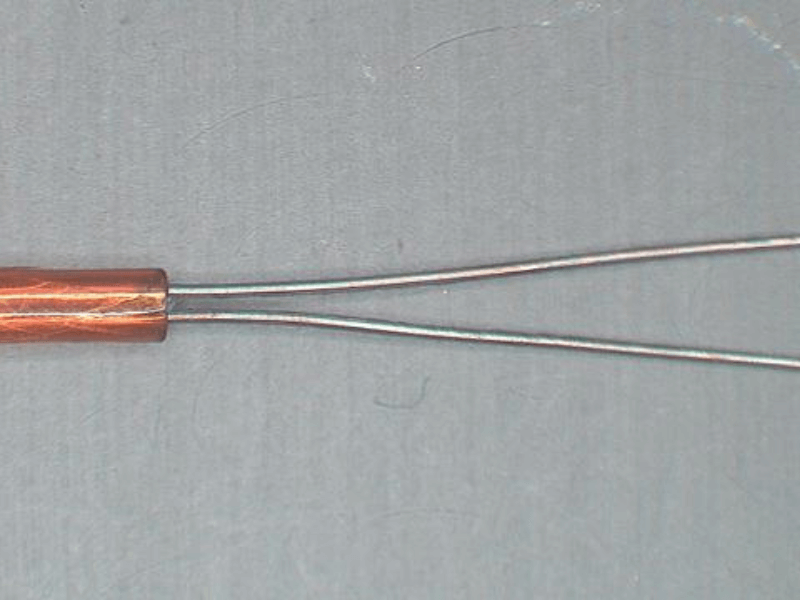

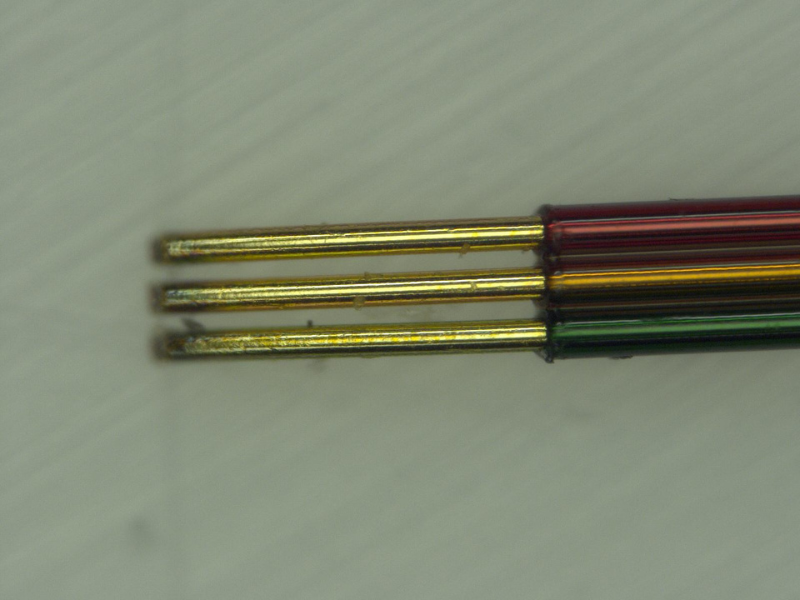

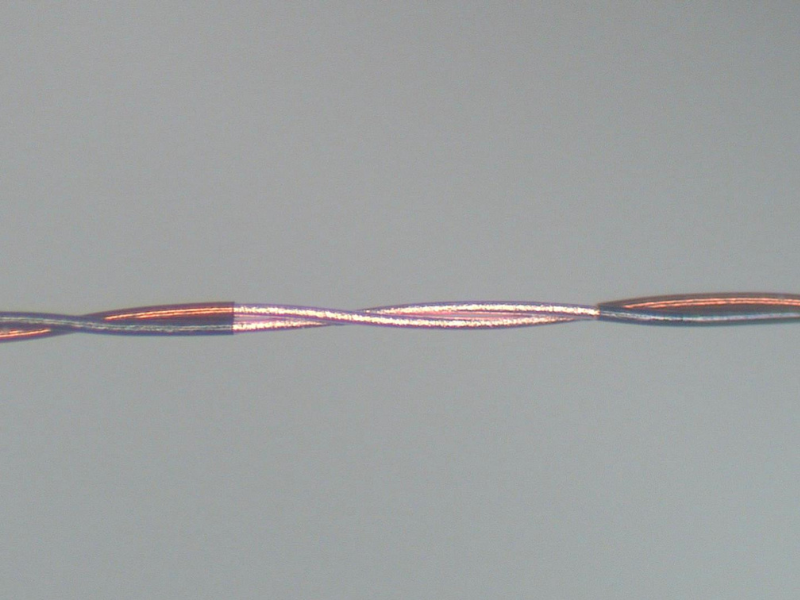

Small gauge enamel wires usually found in cardiovascular ablation & mapping catheters, neurovascular pull wires, stimulation electrodes.

Laser wire stripping offers a superior solution for the following applications by selectively removing insulation without harming the wire or producing hazardous waste:

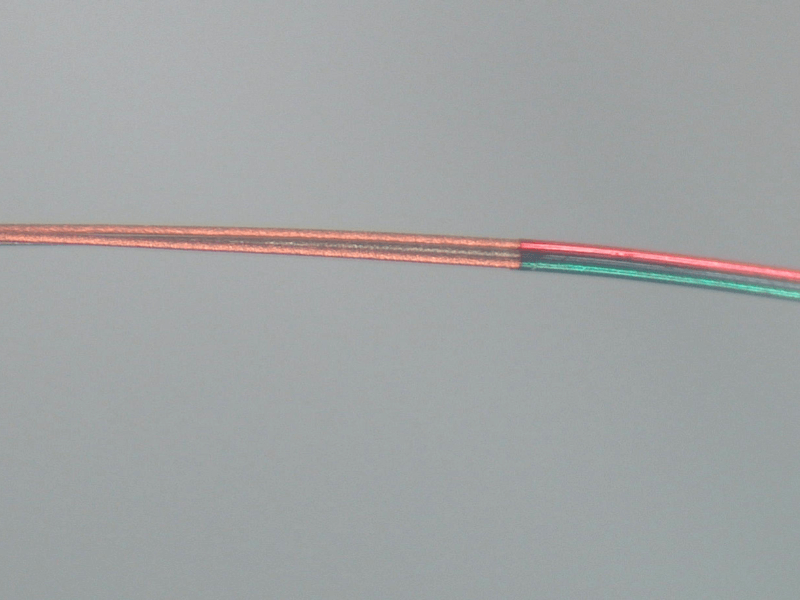

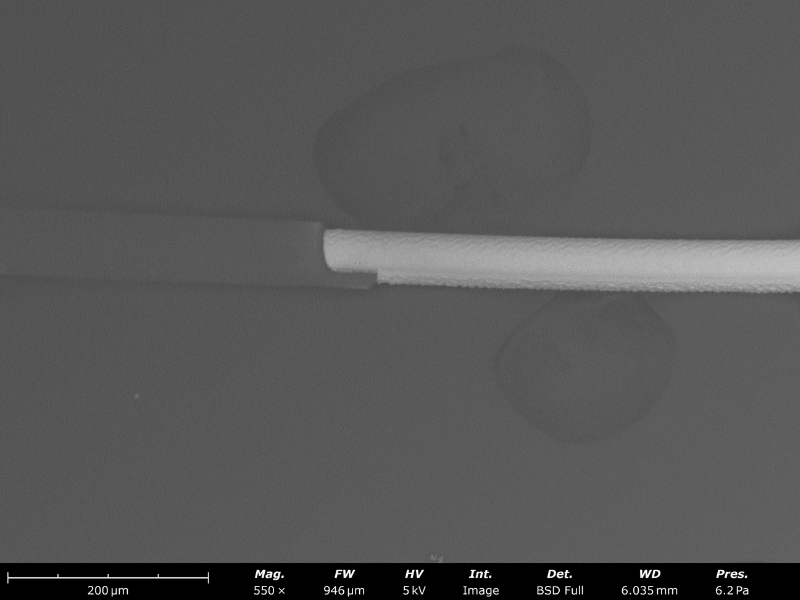

The laser’s attributes allow for precise polymer ablation without affecting metal or leaving residue.

In the production of ablation catheters for cardiac arrhythmia, a significant yield issue was encountered due to the manual stripping of 42AWG enamel wires, which resulted in poor bond strength and occasional explosions during the resistance welding process.

The customer wanted to explore the use of lasers to remove the insulation instead of relying on their operator skill level. Following a successful sample process, the customer found laser stripping, which, when tested, demonstrated a remarkable increase in bond strength by 100%.

Recognizing the potential of this method, the laser process was implemented across over 40 manufacturing lines. This strategic move led to an increase in the overall production yield by more than 1%, translating into multi-million dollar savings per year.

This case study exemplifies the power of innovative solutions in overcoming manufacturing challenges and enhancing operational efficiency.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2024 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd CF37 5YR.

How can we improve your experience?

Please take our short survey here.

Discover the capabilities of our machines with your application before you buy.