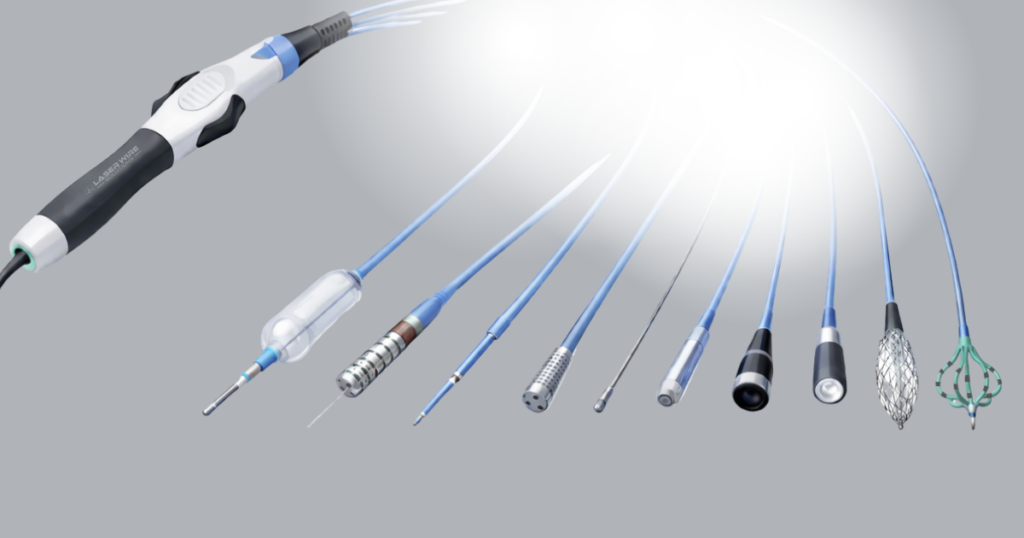

Laser wire stripping is often selected because it simplifies production.

No blades to replace.

No mechanical wear.

No constant adjustment.

That advantage is real, and significant. However, it can also lead to a common misconception: that laser wire stripping requires no maintenance at all.

In reality, laser systems are low maintenance, not maintenance-free. Understanding this distinction is essential for protecting strip quality, maintaining process stability, and ensuring long-term system performance.

A Different Maintenance Model

Traditional mechanical wire stripping depends on physical contact. Over time, blades dull, tolerances drift, and performance degrades as components wear.

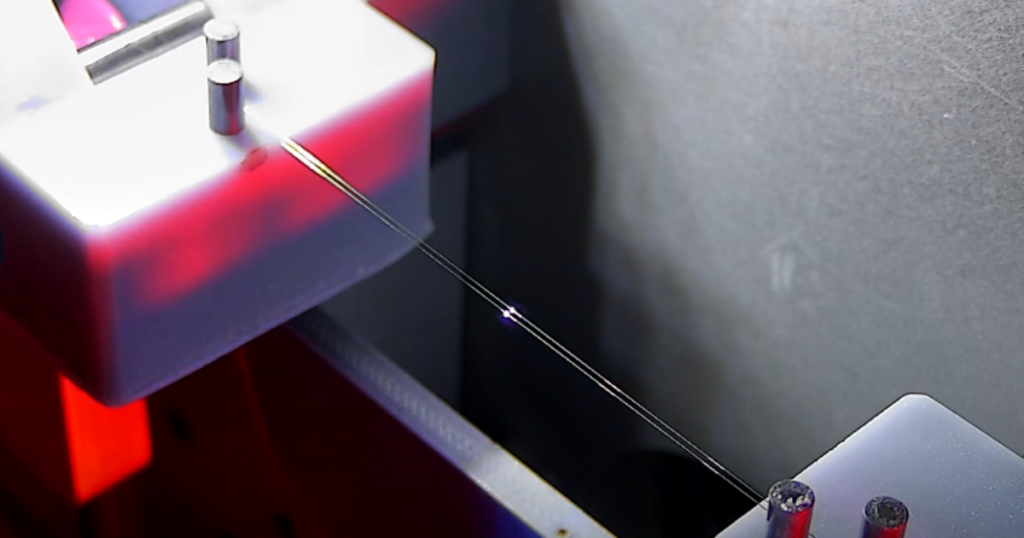

Laser wire stripping removes insulation using precisely controlled laser energy, without touching the wire. This fundamentally changes the maintenance equation:

-

No cutting edges to wear

-

No mechanical forces acting on the conductor

-

No frequent realignment to maintain accuracy

The result is a process designed for consistency—provided the conditions around the laser are maintained correctly.

What Still Matters in a Laser Stripping System

Across modern laser wire stripping systems, routine maintenance focuses on a small number of essentials. They are simple, but they are critical.

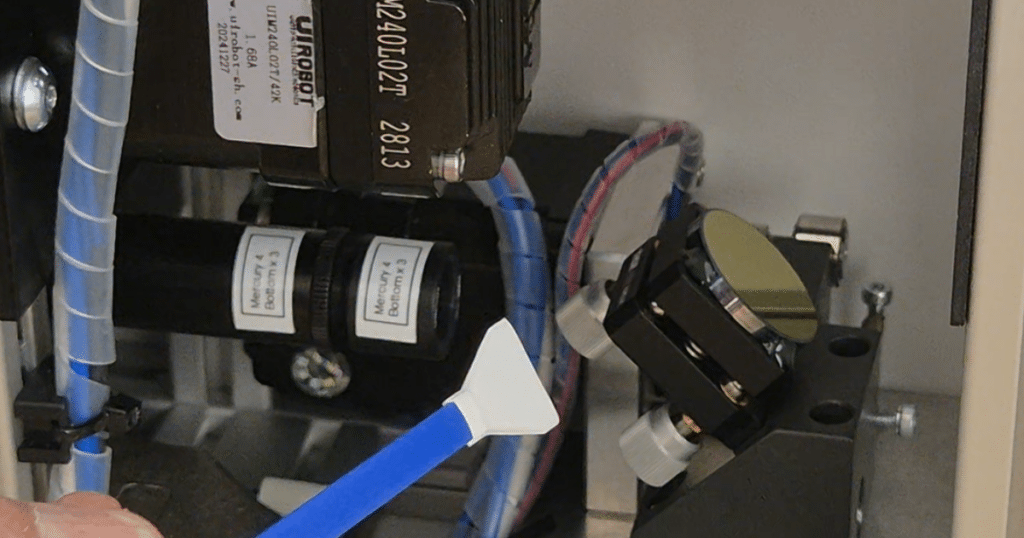

Optical Cleanliness

A laser is a precision tool. Clean optics ensure laser energy is delivered exactly as intended. When debris or residue is allowed to accumulate, strip quality can change gradually, often without an obvious cause.

Routine inspection and light cleaning eliminate this risk entirely, preserving consistency over time.

Effective Fume Extraction

Fume extraction is not an accessory. It is an integral part of the laser stripping process.

Proper extraction:

-

Protects operators from harmful fumes

-

Prevents contamination of internal components

-

Preserves long-term strip quality

Reduced airflow or clogged filters can impact performance even when the laser itself is functioning perfectly. Maintaining the extraction system is one of the most effective ways to protect overall process stability. Laser Wire Solutions systems are provided with the correct fume extraction system, or factory extraction may be used. Whichever method you choose, ensuring it is well maintained is important for ensuring your machine operates correctly.

Routine System Checks

Laser stripping systems are designed to make machine health visible. Regular checks confirm that safety systems, interlocks, and operating conditions remain exactly as intended.

These checks are quick, predictable, and require no specialist mechanical intervention, yet they play a crucial role in maintaining confidence in the process.

The Real Risk: Quiet Variation

When laser systems are neglected, they rarely fail in obvious or dramatic ways.

Instead, variation appears slowly.

This may show up as:

-

Subtle changes in strip appearance

-

Increased recipe adjustments

-

Additional inspection or rework

In high-value or regulated manufacturing environments, this kind of drift matters. Preventive maintenance protects not only the machine, but the repeatability of the process itself.

Designed for Simplicity, Not Neglect

Laser wire stripping machines are engineered to minimize intervention, consumables, and downtime. Maintenance is deliberately straightforward and predictable.

The goal is not to remove responsibility from the user, but to make care intuitive and proportionate, supporting long-term reliability without unnecessary complexity.

When routine maintenance is carried out as intended, laser wire stripping delivers exactly what it is designed to deliver:

-

Consistent results

-

Stable performance

-

Confidence in the process, day after day

Maintenance as Part of a Reliable Process

Low maintenance is one of the defining strengths of laser wire stripping. Routine maintenance is what protects that strength over time.

By treating maintenance as a simple, preventive habit – rather than a reactive task – manufacturers ensure their laser stripping systems continue to perform exactly as expected, long after installation.

If you’re unsure of the maintenance schedule for your system, your manual is the best first place to check, but if you require additional support for your Laser Wire Solutions machine, please request support here.