Laser wire stripping preserves signal integrity and accelerates installs, no conductor bending, no residue, and configurations for any workflow.

Data centers power cloud computing and AI-driven innovation. As demand for faster transmission grows, precision in cable processing becomes non‑negotiable. Our laser wire stripping protects high‑speed cable integrity, minimizing signal loss and optimizing performance for next‑gen infrastructure.

Signal loss from imprecise cable prep

Inconsistent quality with manual methods

Delays & rework slowing installations

As data centers, SANs, and HPC systems scale, cable processing precision is no longer optional — it’s critical.

Laser Wire Solutions delivers flawless, contactless stripping for mission-critical speed.

No conductor bending — protects integrity

Residue-free for minimum dielectric gaps

Configurable workflow — semi-automated or fully automated

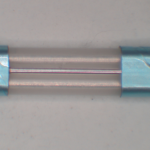

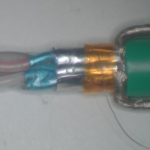

Single drain wire

Two drain wires

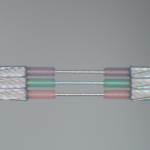

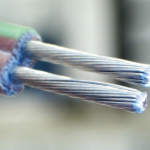

Twisted pairs

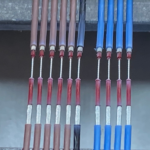

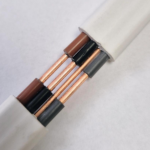

Twin Ax shields

Twin Ax jackets & dielectrics

Infiniband cables

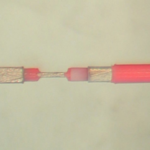

Coaxial cables

No. The process is contactless. The light reflects away from the conductor meaning there's no risk of nicking or bending.

No, depending on the material or cable type, lasers completely ablate the material or cut through the material ready for clean removal of the insulation. This results in the minimum gap required from the dielectric.

Lasers are suitable for a wide range of cable types, and it's highly likely that Laser Wire Solutions has seen your cable type. The best way to be sure, is to submit a free sample for processing.

The right machine depends upon your cable type or material which is used because different lasers interact with materials in different ways. The right machine for you may also be semi-automatic or fully automatic. The Laser Wire Solutions team can advise accordingly. Get in touch to find out more.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, aerospace, defense and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.