Market Applications

Medical

Experience the assurance of having a dedicated ally in advanced medical devices. We specialize in crafting machinery that effectively handles the micro wires within premium implants, instruments, and machines.

These innovations play a pivotal role in enhancing disease diagnosis, treatment, and prevention, providing your customers with improved healthcare outcomes and peace of mind.

From catheters to hearing aids, and advanced pacemakers, our solutions encompass it all.

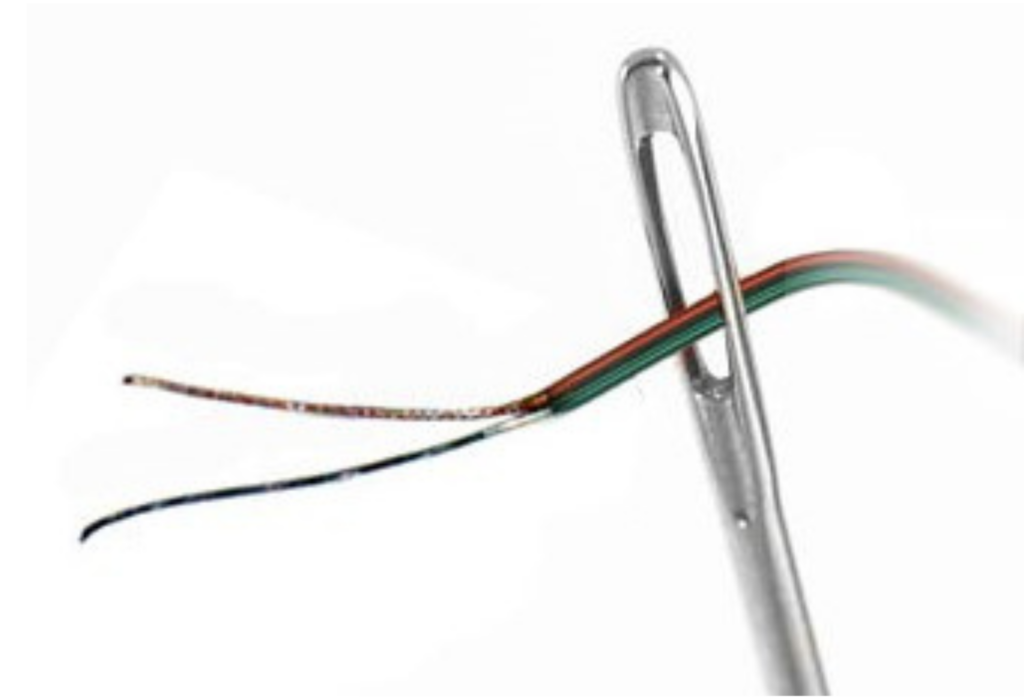

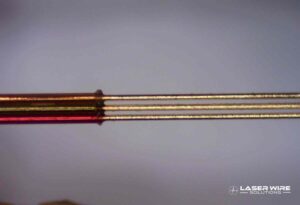

Micro-Fine Wires

These wires have been stripped using Laser Wire Solutions technology

Patient safety is at the forefront of our mind, just like it is for you. By ensuring our wire stripping processes provide minimal residue on the wires used in medical devices, you can ensure your products and your customers are left happy and healthy (and their patients are too!). Using our in-house scanning electron microscope (SEM), we can test your wire then check for any residues on wires finer than a human hair.

Market Application

- Electrical Catheters

- Ablation catheter: uses RF energy to burn cells

- Mapping catheter: measures signals from heart cells using multiple electrodes

- Mechanical Catheters

- Pull wires/Guide wires with coatings

The Wires

- Electrodes

- enamel

- polyimide

- polyester – sizes 0.020-0.20mm (<40 AWG)

- Thermocouples:

- bonded enamel wires – bifilar, multifilar

- Conductors:

- copper

- monel

- gold coated

- Draw wires:

- stainless steel

Traditional Technology Drawbacks

- Stripping requires operator skills

- Yield depends on the skill of the operator

- no traceability

- Poor stripping

- can be over stripped, leading to wires snapping

- High skill level requirement

- lengthy training process,

- slow to ramp up production

- Unable to automate the process

Our Solution

Odyssey 4

- UV laser – Precise ablation of the insulation

- Fixture plates to hold one or many wires (as required)

- Quality check camera option

Why Choose the Odyssey-4?

- Eliminates drawbacks encountered with using abrasive wheels, and direct heat with a soldering iron

- Used by Medical Device OEMs around the world

- Process control that can be validated

- Can be used to strip or cut

- Precise geometry by software control

- Highly repeatable

- High yield process

- Non-contact process, no wear and tear on parts

Not looking to make a capital investment?

Utilize our Contract Manufacturing suite for pre-stripped wire to be delivered direct to your production line ready for use.

Test Our Machines for Your Application

Send us a free sample of your micro-fine wire to put our technology to the test for your application.