The Challenge of Setup Time in Wire Stripping

Setup time has long been one of the most significant barriers to efficiency in wire processing. Whether you’re preparing complex harnesses for aerospace systems or assembling fine medical devices, traditional wire stripping involves frequent adjustments, manual calibrations, and tooling changeovers. These time-consuming steps lead to costly production delays and inconsistent quality.

Laser wire stripping technology changes that. By replacing mechanical tools with programmable lasers, manufacturers can eliminate setup time, improve precision, and enhance overall throughput, all while ensuring consistent results.

Understanding the Basics of Wire Stripping Processes

Wire stripping is a vital step in electrical assembly, involving the removal of insulation from a wire to expose the conductor for connection or termination. While the goal is straightforward, the process itself can vary greatly depending on the technology used.

Manual and Mechanical Wire Stripping Limitations

Traditional wire stripping relies on blades or mechanical tools. While effective for small-scale work, these methods often struggle with consistency, especially across different wire gauges and insulation types. Manual calibration adds hours of setup time when switching between jobs.

The Evolution of Automated Wire Stripping

Automation brought speed and consistency, but it didn’t fully solve the setup issue. Mechanical systems still depend on precise tooling adjustments and blade changes. Each new wire specification means downtime, until laser wire stripping arrived.

What is Laser Wire Stripping?

Laser wire stripping is a non-contact method that uses a focused laser beam to vaporize insulation without touching or damaging the conductor. It’s fully programmable, highly precise, and suitable for nearly any wire or cable type.

How Laser Wire Stripping Works

A laser beam is directed at the wire’s insulation layer. The laser’s wavelength and power are precisely tuned to absorb only into the insulation, leaving the conductor untouched. With CAD-driven software, operators can instantly adjust strip lengths, positions, and geometries without mechanical intervention.

Types of Laser Wire Stripping Technologies

-

CO₂ Lasers: Ideal for larger wires and PVC or Teflon insulation.

-

UV Lasers: Best for micro wires used in medical and electronics industries.

-

Fiber Lasers: Excellent for marking and partial stripping applications.

Each laser type is selected based on insulation material and wire application, making the process adaptable to multiple industries.

The Role of Laser Wire Stripping in Eliminating Setup Time

No Tooling Changeovers Required

Unlike mechanical strippers, laser systems don’t use blades or mechanical contact. This means no blade wear, sharpening, or replacement and no downtime between jobs. Setup becomes digital rather than manual.

Instant Programming for Different Wire Types

Laser systems store wire profiles in a digital library. Operators can switch from one wire type to another with a few clicks, zero mechanical adjustment needed. This makes the process ideal for high-mix, low-volume production environments.

Key Advantages of Laser Wire Stripping

Superior Accuracy and Quality Control

Laser systems deliver micron-level precision, ensuring clean edges and consistent strip lengths. Since there’s no physical contact, the risk of nicking or damaging conductors is virtually eliminated.

Reduced Scrap and Material Waste

By avoiding conductor damage and minimizing rework, laser stripping drastically cuts material waste. Over time, this leads to measurable cost savings and a more sustainable manufacturing process.

How to Implement Laser Wire Stripping in Your Production Line

Integration with Existing Automation Systems

Modern laser strippers are designed to integrate seamlessly with automated wire processing lines. They can connect to conveyors, robots, and quality control systems for a fully synchronized workflow.

Training and Workforce Optimization

Operators quickly adapt to the technology. Instead of managing complex tooling setups, they focus on programming and monitoring. This shift not only eliminates setup time but also reduces human error.

Real-World Applications and Industry Examples

Laser wire stripping has become the preferred choice across industries where precision is critical:

-

Aerospace: For Teflon-coated wires in flight systems.

-

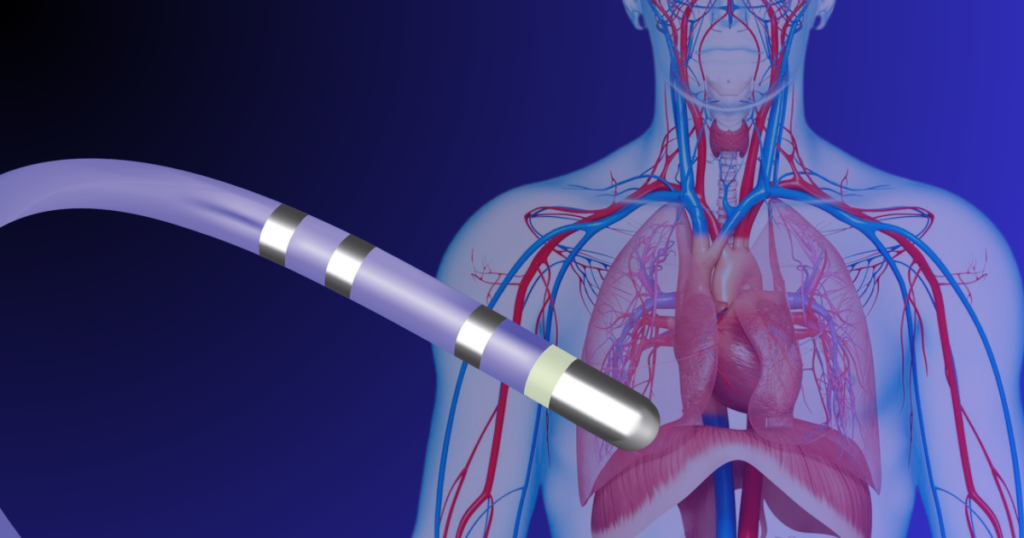

Medical Devices: For micro wires in catheters and sensors.

-

Automotive: For electric vehicle battery and harness production.

These industries rely on zero-defect performance something only laser stripping can consistently deliver.

ROI and Cost-Benefit Analysis

Though laser systems may require higher upfront investment, the long-term savings from reduced downtime, scrap reduction, and maintenance far outweigh the costs. Most manufacturers report ROI within 12–18 months of adoption.

Common Myths About Laser Wire Stripping

-

Myth: Lasers damage the wire.

Fact: Properly tuned lasers never touch the conductor. -

Myth: Lasers are too complex to operate.

Fact: Modern systems use intuitive software interfaces. -

Myth: Only for high-end applications.

Fact: Increasingly affordable and scalable for all industries.

FAQs – Everything You Need to Know

1. Does laser wire stripping work on all insulation types?

Yes. It’s effective on PTFE, Kapton, PVC, and even enamel-coated wires.

2. Can laser stripping handle multi-conductor cables?

Absolutely, systems can be programmed for complex geometries and multi-core cables.

3. Is laser wire stripping safe?

Yes. With proper shielding and ventilation, the process is completely safe for operators.

4. How much maintenance do laser systems need?

Minimal. No moving parts mean no blade replacements or alignment checks.

5. Does it support mass production?

Yes. Laser systems are used in high-speed automated production lines globally.

6. How quickly can I switch between different wire types?

Instantly, no mechanical changes, just digital configuration updates.

Future of Zero-Setup Wire Processing

Laser wire stripping represents the future of wire processing; fast, precise, and fully digital. By eliminating setup time and tooling changeovers, it transforms productivity and consistency across industries. As technology advances, the gap between traditional and laser methods will only grow wider, making laser wire stripping the gold standard for modern manufacturing.