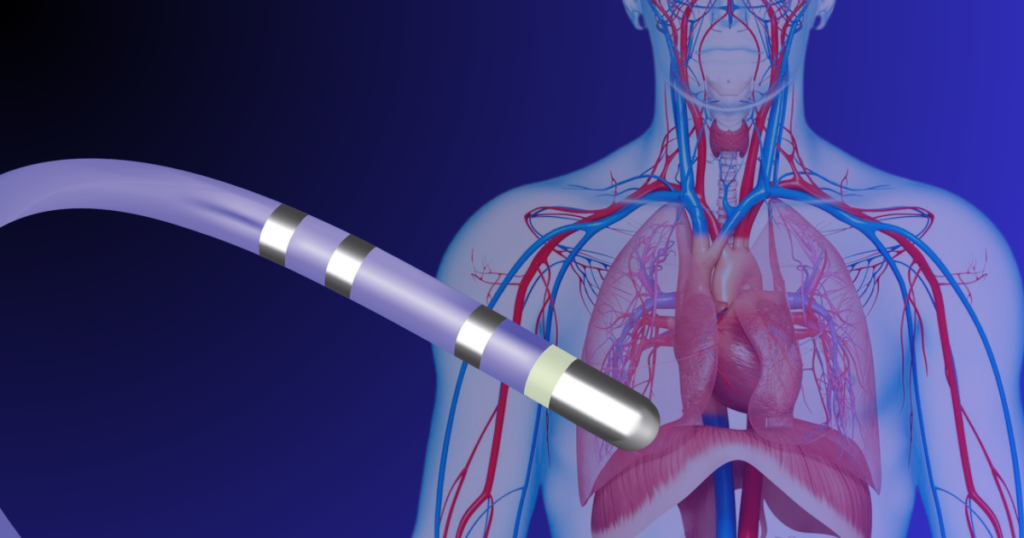

In electrophysiology / EP catheter manufacturing, precision is everything. Each catheter can contain dozens of hair-thin wires, connecting electrodes, sensors, and thermocouples that must perform flawlessly inside the human heart.

Yet despite incredible advances in materials and design, one crucial process often remains stuck in the past: manual wire stripping.

The Hidden Bottleneck in EP Catheter Production

In most manufacturing lines, operators still strip wires under microscopes using tweezers, blades, or micro-abrasive tools. The process depends entirely on operator skill, the pressure applied, the rotation of the wire, and even the steadiness of a hand.

That might sound manageable in R&D. But at scale, it’s a high-risk bottleneck that can create multimillion-dollar consequences:

-

Low and variable yields due to inconsistent stripping quality

-

Delayed validation when manual steps can’t be easily qualified under FDA 21 CFR 820.75

-

Costly scrap and rework, sometimes exceeding $0.5M per line per year

-

Risk of field failures from weakened conductors or residual insulation

As global demand for Pulsed Field Ablation (PFA) catheters grows, these challenges multiply. Manual methods can’t keep pace with increasing production volumes or the reliability demands of next-generation EP systems.

Laser Wire Stripping: The Shift from Operator Skill to Process Control

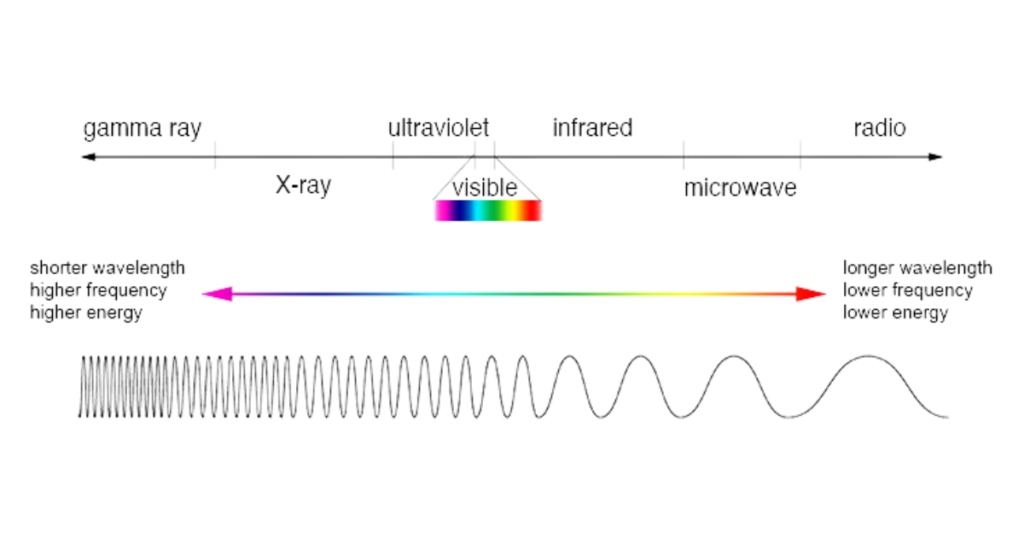

Laser wire stripping replaces manual, mechanical steps with a controlled, automated process. Using pulsed ultraviolet (UV) lasers, the insulation is vaporized in microns-thin layers — without damaging the conductor.

Unlike mechanical scraping, laser stripping is:

-

Non-contact: no pressure, no nicks, no weakened wires

-

360° precise: removes insulation evenly around the wire

-

Fully measurable: laser parameters can be validated and repeated with confidence

This means consistent quality, faster validation, and easier integration into automated assembly lines.

In short, laser stripping turns a manual art into a scientific process, one that meets the demands of modern catheter manufacturing.

From Validation to Automation: A Foundation for the Future

Today’s EP catheter manufacturers face growing pressure to automate. But true automation can’t happen when critical steps still rely on operator “feel.”

Laser wire stripping provides the foundation for scalable, semi- or fully automated manufacturing. OEMs implementing it now are gaining a long-term competitive edge, cutting costs, improving yields, and accelerating time to market.

As one engineering manager noted:

“Payback was well under 12 months. After seeing the results on one line, we switched all 60 lines to laser stripping.”

Discover the Full Technical and Financial Case

This article highlights just one part of the full story. Our detailed whitepaper, “Laser Wire Stripping of Cardiology EP Catheters: Achieving a Competitive Edge in the PFA Era” explores:

-

Real-world case studies from leading OEMs

-

Validation strategies for IQ/OQ/PQ compliance

-

ROI analysis showing >$0.5M annual savings per line

-

How laser stripping future-proofs EP catheter manufacturing for automation

Get instant, free access to the whitepaper here.