Laser wire processing has revolutionized industries that rely on high-precision wire stripping and preparation. From aerospace to medical device manufacturing, companies need accurate, repeatable, and efficient methods to handle delicate wires. One of the key determinants of success is not just the laser itself but how wires are loaded into the system. This is where Laser Wire Solutions offers tailored wire loading options, fixture, single wire insert, and integrated/inline systems.

Why Wire Loading Options Matter in Laser Wire Solutions

Choosing the right wire loading method impacts precision, throughput, and cost-efficiency. Whether you’re prototyping a medical catheter or mass-producing automotive wiring harnesses, the right loading strategy can improve workflow, reduce waste, and ensure compliance with strict quality standards. Each option, fixture-based, single wire insert, and integrated/inline, serves a distinct purpose depending on the production environment.

Overview of Wire Loading Options

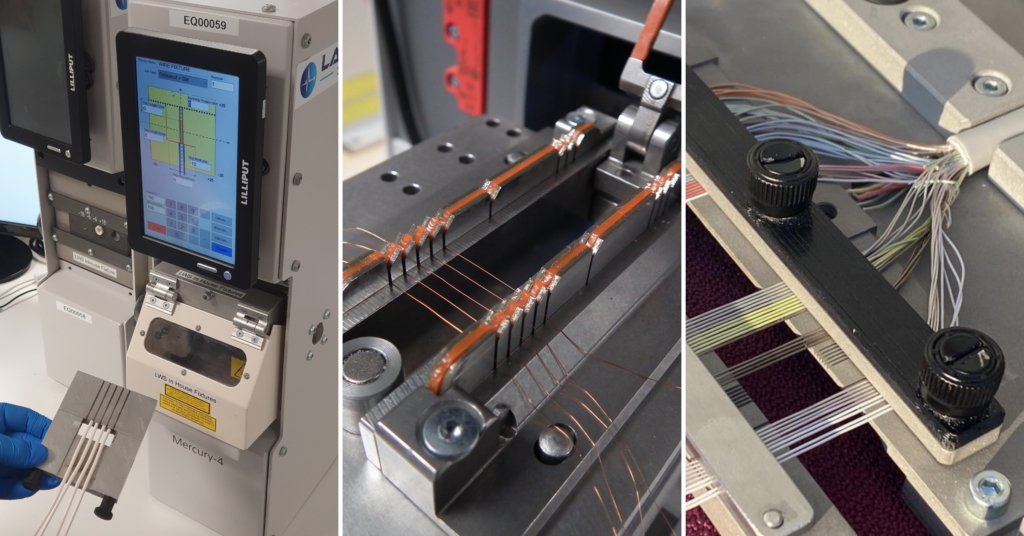

Fixture-Based Wire Loading

Fixture-based systems use custom-designed holders or jigs to secure wires during laser processing. This ensures repeatability and accuracy, especially for small or intricate wires.

Single Wire Insert Loading

This method allows operators to manually insert a single wire into the machine for processing. It’s ideal for low-volume production, prototyping, or cases where wire size or configuration changes frequently.

Integrated/Inline Wire Loading

Designed for high-speed, automated production lines, integrated or inline systems feed wires continuously through the laser stripping machine, maximizing throughput for large-scale manufacturing.

Fixture-Based Wire Loading: Advantages & Applications

Precision and Repeatability

Fixture-based systems excel at delivering consistent results, making them essential for industries where precision is non-negotiable. Laser Wire Solutions can also work with you to design a custom fixture plate to suit your wire and the machine you’ll be using.

Common Use Cases in Aerospace and Medical Devices

Aircraft wiring and catheter assembly often require this method due to strict tolerance requirements.

Limitations of Fixture Loading

While accurate, fixture systems can be slower to set up and less efficient for high-volume production.

Single Wire Insert Loading: Pros and Cons

When to Choose Single Wire Insert Loading

This option is perfect for laboratories, R&D environments, or startups working on prototypes.

Benefits for Prototyping and Small Batches

Its flexibility allows quick adaptation to different wire types without expensive tooling.

Limitations Compared to Other Methods

Manual loading increases cycle time, making it less suitable for mass production.

Integrated/Inline Wire Loading: Efficiency at Scale

Automation and Speed Benefits

Inline systems can handle thousands of wires per shift, seamlessly integrated into automated assembly lines.

High-Volume Manufacturing Applications

Automotive harness production and consumer electronics manufacturing rely heavily on this method.

Challenges and Setup Considerations

The initial investment is higher, and setup requires expertise to ensure synchronization with upstream and downstream processes.

Comparing All Three Wire Loading Options

Fixture vs. Single Wire Insert

Fixture-based systems provide unmatched consistency, but they require more setup time and are better suited for repetitive tasks with strict tolerances. In contrast, single wire insert systems are more flexible but less efficient for repetitive, high-volume tasks. The choice comes down to whether precision or adaptability is more important for your project.

Single Wire Insert vs. Integrated/Inline

For companies scaling up from prototype to production, this comparison is crucial. Single wire insert loading is cost-effective and easy for small batches but can’t match the efficiency of inline systems. Integrated systems streamline production but come with higher upfront costs and require process standardization.

Fixture vs. Integrated/Inline

These two represent opposite ends of the spectrum. Fixture systems deliver precision for specialized applications, while inline systems focus on volume and efficiency. Choosing between them depends largely on whether your priority is accuracy or throughput.

Choosing the Right Wire Loading Option for Your Project

Factors: Volume, Wire Type, and Industry Standards

-

Volume: Small-batch projects benefit from single wire inserts, while high-volume automotive or electronics manufacturing calls for inline systems.

-

Wire Type: Extremely delicate or custom wires may require fixtures for stable processing.

-

Industry Standards: Aerospace and medical applications often mandate fixtures to meet compliance requirements.

Balancing Cost, Precision, and Throughput

Decision-makers should weigh initial investment against long-term benefits. While fixture systems may cost less upfront, integrated/inline systems often save money in the long run due to reduced labor costs and increased productivity.

FAQs on Laser Wire Solutions Wire Loading Options

Q1: What’s the best wire loading option for prototyping?

For prototyping and small batches, single wire insert loading is the best choice due to its flexibility and low setup cost.

Q2: Which option is ideal for medical device manufacturing?

Fixture-based systems are preferred in medical manufacturing because of their precision and ability to meet compliance requirements.

Q3: Can inline wire loading be used for all industries?

Inline systems are best suited for high-volume industries like automotive and consumer electronics. They may not be practical for small-scale operations.

Q4: How do I decide between fixture and inline systems?

Choose fixture systems when precision is paramount and inline systems when volume and efficiency are the priority.

Q5: Are these wire loading options customizable?

Yes, Laser Wire Solutions offers tailored solutions, allowing companies to adapt fixtures, inline setups, or hybrid systems to meet unique requirements.

Q6: Do integrated systems require training?

Yes, operators and engineers need training to ensure smooth setup and maintenance, especially when synchronizing with automated lines.

Selecting the Best Wire Loading Solution

Laser Wire Solutions provides a range of wire loading options, fixture-based, single wire insert, and integrated/inline systems, each suited to different production needs. Fixture systems excel in precision for industries like aerospace and medical devices. Single wire inserts shine in prototyping and low-volume projects. Integrated/inline systems dominate in high-volume sectors like automotive manufacturing.

Ultimately, the best choice depends on balancing volume, precision, and efficiency. As technology evolves, integrating AI, robotics, and smart manufacturing will make these systems even more powerful, ensuring that companies remain competitive in an increasingly automated world.