Why Data Center Cable Prep is Crucial for Cable Manufacturers in 2026

For data center cable manufacturers, 2026 marks a turning point. With demand for bandwidth, speed, and reliability surging due to AI, edge computing, 5G expansion, and global data growth, cable prep is not just about basics, it’s about delivering precision, consistency, and compliance at scale. Innovations in stripping, termination, material science, and quality control are reshaping what “good enough” means. Manufacturers who adopt advanced prep technologies, especially laser wire stripping, along with automation and sustainable production, will lead in meeting hyperscale expectations.

Evolving Landscape: What’s Pushing Manufacturers in 2026

-

The data center wire & cable market is growing rapidly. In 2025 it was estimated at USD 20.91 billion, and forecasts place it rising toward USD 30.63 billion by 2030 with a CAGR of ~7.94%.

-

The data center cabling market more specifically (fiber + copper etc.) is projected to grow from ~USD 7.7 billion in 2025 to ~USD 11.8 billion by 2030. Fiber optic is commanding a growing share, both in backbone and interconnect cabling.

-

On the tool/automation side, the laser wire stripping machine market is forecasted to grow strongly: from around USD 245-$260 million in 2024/2025 toward USD 450-600 million by early 2030s, depending on region and adoption.

These figures underscore that by 2026, both the production demands and the tools needed for high-precision cable prep are becoming more of a differentiator.

2026 Key Trends in Cable Prep for Data Center Cable Manufacturers

Here are several major shifts you should be aware of, and how laser wire stripping fits into them:

-

Fiber Optic and High-Density Systems Become Standard for Backbone and Interconnect

Manufacturers are moving from copper for many high thruput paths toward fiber and higher performance copper (Cat 6A, Cat 8 etc.), demanding cleaner terminations, tighter tolerances, minimal loss. Prep techniques must keep pace. -

Laser Wire Stripping Becomes Mainstream in Production Lines

-

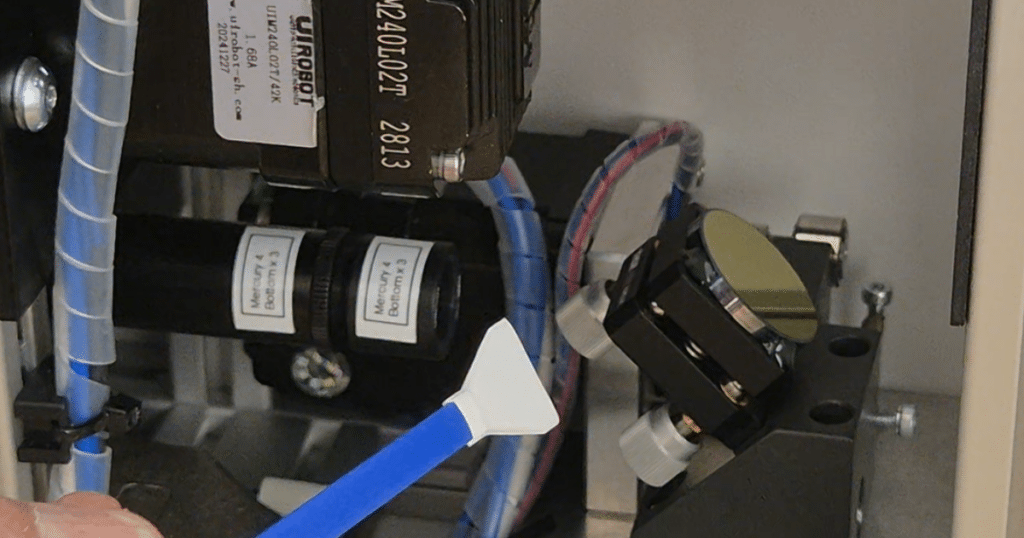

With rising demand for precise, damage-free removal of insulation on fine, multi-coated conductors, laser stripping is increasingly adopted.

-

Market growth forecasts show strong CAGR in laser stripping equipment.

-

Key advantages: non-contact stripping, less mechanical stress, ability to handle very thin insulation, multiple coat types, micro-wires etc.

-

-

Automation & Smart QC Intensifies

In 2026, it’s not enough to automate a step, manufacturers are integrating laser stripping, robotic handling, inline inspection, and feedback loops to detect defects immediately. -

Sustainability, Eco-friendly Materials, Regulatory Pressure

-

Materials such as low-halogen, recyclable jackets, and non-toxic insulations grow in importance.

-

Regulations tightening: e.g. bans or phase-outs of harmful chemical processes (solvent stripping, certain plasticizers). Manufacturers preparing for 2026 should already be in compliance or have alternative methods in place.

-

Also expect customer pressure (data center operators) for environmental credentials.

-

-

Customization & Prefabrication

Data centers (especially hyperscale and edge facilities) want pre-terminated, modular cabling, and prefabricated assemblies to reduce field work, ensure quality, and shorten deployment time. Prep must support this, including laser stripping for precise pre-termination. -

Higher Performance Standards and Latency Sensitivity

Performance expectations are rising: lower insertion loss, better return loss, reduced crosstalk. Cable prep quality influences these. Termination and insulation stripping must be more precise, with finer tolerances.

Best Practices for Cable Manufacturers in 2026

To compete in 2026, manufacturers should adopt or refine these practices:

-

Adopt Laser Wire Stripping Where Precision Matters

Use laser stripping systems especially for fine wires, multi-coated cables, fiber jackets etc. Calibrate systems to avoid overheating or damaging conductors. Combine with inspection (microscope, machine vision) to verify integrity. -

Integrate Inline Quality Control

Real-time inspections, defect monitoring, statistical process control. Reject or rework before termination/connectorization to avoid cascading failures. -

Material Selection & Jacket/Insulation Innovation

Move toward sustainable materials (recyclable plastics, low halogen, bio-based polymers). Ensure coatings that are laser-strip compatible (some materials respond poorly). -

Compliance & Certification

Stay up to date with international standards (TIA, ISO/IEC, IEEE) as well as region-specific rules. Monitor regulatory developments regarding chemicals and environmental impact. -

Optimize Termination & Connectorization Processes

Ensure polishing, splicing, connector alignment are supported by clean prep work. Laser stripping can greatly improve consistency ahead of termination. -

Cost & ROI Assessment

Upfront cost of laser stripping tools, automation etc. is high. But by 2026, payback is clearer via reduced scrap, less rework, faster throughput, lower manual labor. Model TCO (total cost of ownership) properly.

Tools & Technologies to Watch in 2026

-

Laser Wire Stripping Systems

CO₂ lasers, UV lasers, or fiber lasers configured for wire prep. Dual-head or multi-beam lasers allow higher throughput. -

Robotic Handling / CNC Integration

To feed strips, position wires, handle connectors automatically, especially in prefabricated assemblies. -

AI / Machine Vision Inspection

To detect insulation remnants, micro-nicks, conductor distortion, etc., inline. -

Advanced Termination Machines

Connectorization tools with precision alignment, polishing / polishing-free connectors, fusion splicing for fiber. -

Material Analytics / Testing Labs

Labs to test jacket materials for compatibility with lasers, durability, flame resistance, etc.

Challenges and What Manufacturers Must Address in 2026

-

High Initial Investment

Laser stripping plus automation require capital, not just purchase but integration, training, maintenance. -

Skilled Workforce

Need technicians and engineers who understand lasers, materials science, automation, QC methods. -

Supply Chain Constraints

Materials that are both high performance and sustainable may have limited availability. Vendors of precision components, coatings, lasers etc., need reliability. -

Regulatory Risk

Chemical bans, environmental safe materials, energy efficiency. Falling behind regs can cause costly delays or product rework. -

Competition

As more manufacturers adopt advanced prep technologies, differentiation will shift toward marginal improvements: lower defect rates, speed, cost per cable, sustainability credentials.

Why Laser Wire Stripping Is Particularly Crucial in 2026

-

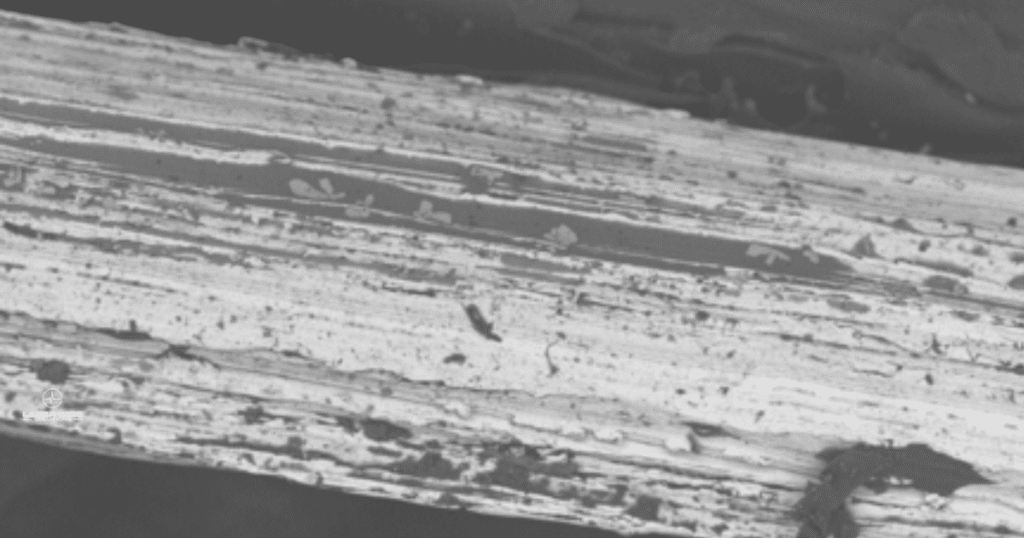

Precision: As cable designs get thinner, more layered, with more varied coatings, mechanical stripping methods are reaching limits. Laser can handle delicate insulation without damaging conductors.

-

Scalability: Laser stripping systems are being designed for inline high throughput; more manufacturers will scale from prototyping/low volume to full production.

-

Regulatory and environmental compliance: Reducing or eliminating use of harmful chemicals or waste associated with mechanical stripping (e.g. solvents, sharp tools) aligns lasers with sustainability goals.

-

Performance Improvement: Termination quality, signal integrity, latency depend heavily on clean stripping, any micro-defect or residual insulation causes loss or interference.

Market Projections & Data You Should Know

-

The laser wire stripping machine market was ≈ USD 245-260 million in 2024/2025, forecast to grow at ~6-7% CAGR to reach roughly USD 450 million (or more) by early 2030s.

-

The data center cabling market will expand strongly from 2026 onward, fiber cable adoption especially, pre-terminated modules, demand from edge facilities.

-

Regulatory pressures: chemical bans (e.g. certain plasticizers like PIP (3:1)) taking effect ~October 2026 for many jurisdictions. Manufacturers using these must have compliant alternatives.

FAQs for Cable Manufacturers in 2026

Q1: Is laser wire stripping cost-effective for small to medium-scale manufacturers by 2026?

Yes, while upfront cost remains high, reductions in scrap, rework, labor savings, and improved quality make payback more feasible, especially if leveraged in higher-density cable lines or pre-terminated assemblies.

Q2: What wires or insulation types benefit most from laser stripping?

Fine gauge wires, multi-coated insulation, delicate optical fiber jackets, materials that are hard to strip mechanically without damaging conductor (thin polymer coatings, PTFE etc.).

Q3: Are there risks associated with laser wire stripping?

Like any industrial process, laser wire stripping carries potential risks, but these are well-managed with the right equipment and training. Most of Laser Wire Solutions’ systems are Class 1 laser machines, meaning they’re inherently safe for shop-floor operation without requiring additional PPE, except during maintenance. We provide comprehensive training so operators can use the systems confidently and correctly.

On the technical side, the process is designed to protect the conductor. The stripping parameters—such as power, wavelength, and exposure time—are fully programmable, ensuring the laser only removes insulation. Because the laser energy reflects harmlessly off the conductor surface, there’s no cutting, nicking, or abrasion risk as with mechanical methods. In practice, this makes laser stripping one of the safest and most precise ways to prepare wires and cables, even for delicate or high-value applications.

Q4: What standards/regulations should manufacturers watch in 2026?

International standards (TIA/EIA, ISO/IEC, IEEE), as well as regional chemical safety regulations (e.g. bans on PIP (3:1) plasticizers), environmental regulations about flame retardants, low halogen content, recyclability.

Q5: How much does adopting laser stripping improve performance?

Improvements include reduced defect rates (e.g. fewer micro-nicks), more consistent terminations (better signal integrity, lower insertion / return loss), potentially lower latency, better lifespan under mechanical stress.

Q6: Will automation replace human skill entirely?

Not entirely. Even in 2026, human oversight, maintenance, material knowledge, quality assurance are vital. Automation (including laser stripping) amplifies efficiency and consistency, but skilled operators are needed for setup, monitoring, and dealing with anomalies rather than in the actual stripping of wires.

Conclusion

By 2026, the competitive stakes for data center cable manufacturers will be higher. The market isn’t just growing, it’s becoming more demanding in terms of speed, reliability, sustainability, and cost control. For manufacturers, laser wire stripping stands out as one of the most transformative technologies in cable prep, especially for high density, fiber-rich, eco-aware production lines. Combine that with strong automation, strict QC, regulatory compliance, and material innovation, and manufacturers will not only keep up, they’ll set the standard for what “premium cable prep” means in the data center world.