Traditional stripping tools, whether it’s mechanical blades or thermal tweezers, often risk nicking, contaminating, or deforming conductors during insulation removal. That’s where laser wire cutting and stripping technology comes in. Using the power of precisely controlled laser beams, this non-contact process can cut, score, or vaporize insulation with micron-level accuracy, without ever touching the conductor beneath. Depending on the insulation type, the laser may either ablate the coating completely or make precision cuts that allow the operator to peel off the insulation cleanly.

This dual capability, combining laser ablation for thin coatings and laser cutting for thicker, tougher materials, makes laser wire cutting and stripping one of the most advanced and reliable solutions in modern wire processing.

Understanding Laser Wire Stripping Technology

What Is Laser Wire Stripping?

Laser wire stripping involves using high-intensity light beams to remove insulation from wires. Depending on the material, the laser can:

-

Vaporize the insulation through ablation.

-

Cut or score the insulation for manual removal.

This method is contact-free, eliminating mechanical wear and ensuring repeatable precision across thousands of operations.

Evolution from Mechanical to Laser Methods

Historically, technicians used mechanical blades, chemical baths, or thermal cutters, each introducing potential damage or residue. As wire sizes became smaller and insulation materials more complex (e.g., PTFE, Kapton), laser stripping emerged as the most reliable alternative, offering clean cuts, no conductor contact, and no tool wear.

Key Advantages of Laser Wire Stripping

-

Non-contact operation prevents conductor damage.

-

Cuts and vaporizes with high repeatability.

-

No chemicals, consumables, or mechanical wear.

-

Compatible with complex multi-layer wires.

The Science Behind Laser Wire Stripping

How Lasers Interact with Different Materials

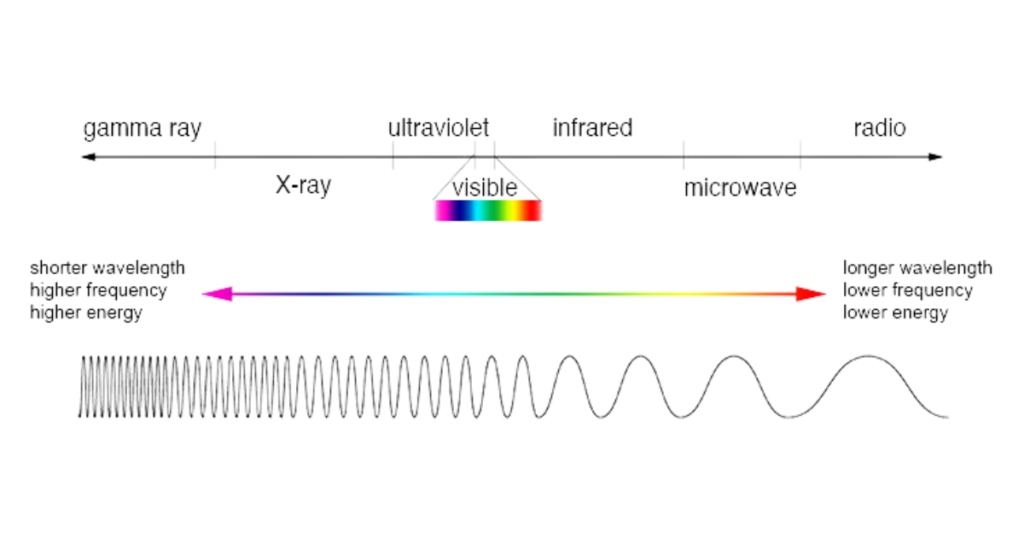

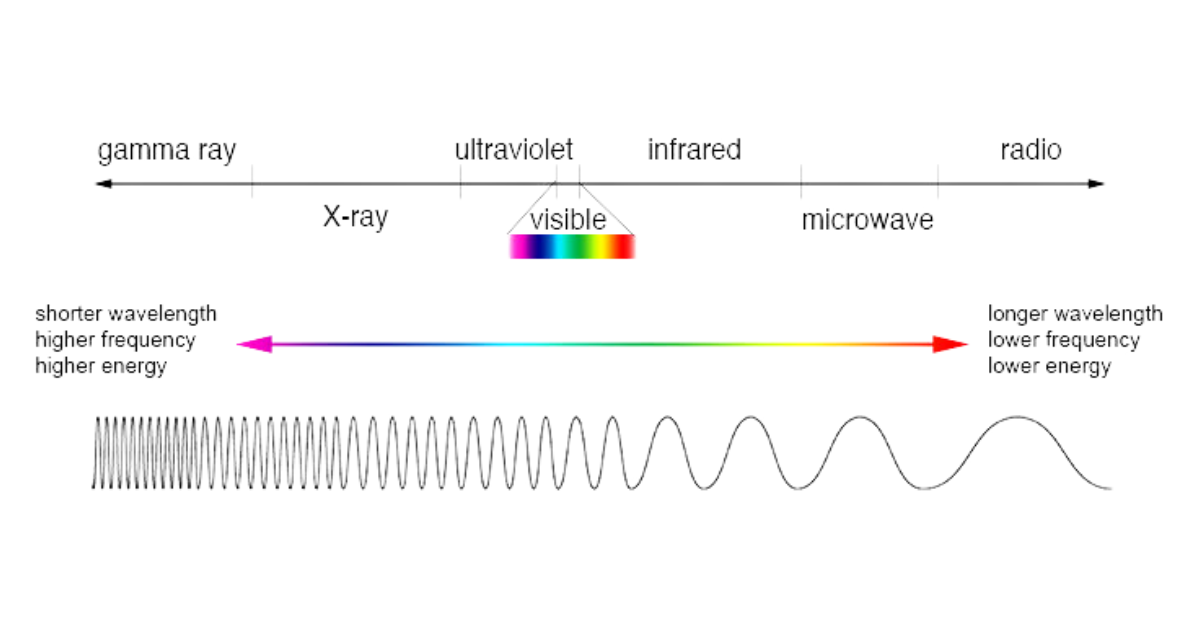

Laser wire stripping relies on the interaction between the laser wavelength and the material’s absorption properties. Some insulations absorb the laser’s energy efficiently and vaporize cleanly, while others resist vaporization but can be precisely cut along defined paths for peeling.

Selective Absorption and Controlled Cutting

When vaporization isn’t feasible, such as with thick insulations, the laser’s energy is used to cut through the insulation layer without penetrating the reflective metal beneath. The key lies in laser control: tuning pulse duration, energy density, and focus depth to cut just deep enough to separate the insulation, leaving the conductor unharmed.

Role of Wavelength and Beam Focus

Different wavelengths serve different functions:

-

Infrared lasers cut or score polymer coatings (the Mercury range).

-

UV lasers provide cold ablation for thin or delicate insulation (the Odyssey range).

-

Fiber lasers are used for thicker, high-performance materials (the Gemini range).

By adjusting focus and pulse parameters, operators achieve either full removal (ablation) or controlled cutting for manual peeling.

Types of Lasers Used for Insulation Stripping and Cutting

CO₂ Lasers (Infrared, 10.6 µm)

Ideal for organic and polymer-based coatings like PVC or Teflon. These lasers often cut or score the insulation rather than vaporizing it, enabling clean removal through peeling.

UV Lasers (355 nm)

Used for thin or delicate coatings, UV lasers rely on cold ablation to vaporize insulation directly. They are perfect for micro-coaxial cables and medical enamel wires where minimal heat is critical.

Fiber and Nd:YAG Lasers

These lasers can operate in both cutting and ablation modes, suitable for industrial-scale stripping where precision and throughput are equally important.

Step-by-Step: How Lasers Strip or Cut Insulation Without Damaging the Conductor

Step 1: Material Identification

The process begins by identifying insulation type, color, and thickness. This determines whether ablation or cutting is more effective.

Step 2: Parameter Configuration

Laser parameters such as wavelength, pulse width, focus depth, and beam path are fine-tuned. For materials unsuitable for vaporization, the laser is programmed to score or cut just deep enough for clean peeling.

Step 3: Ablation or Cutting

-

In ablation mode, the insulation is vaporized entirely and extracted by vacuum.

-

In cutting mode, the laser traces circular or linear paths, scoring the insulation around the wire for manual or automated peeling.

Step 4: Inspection and Cleaning

After processing, operators inspect the stripped region for residual insulation or conductor exposure. Non-contact cameras verify accuracy before the wire moves to the next production stage.

The Laser Wire Solutions Samples Team can identify the correct parameters for your application via a Sample Report.

Laser Stripping vs. Traditional Techniques

| Method | Contact Type | Precision | Conductor Safety | Suitable for Thin Wires |

|---|---|---|---|---|

| Mechanical | Contact | Low | High Risk | Poor |

| Chemical | Contact | Medium | Moderate | Moderate |

| Thermal | Contact | Medium | High Risk | Fair |

| Laser (Ablation) | Non-Contact | Very High | Excellent | Excellent |

| Laser (Cutting + Peeling) | Non-Contact | Very High | Excellent | Excellent |

Laser systems can switch seamlessly between cutting and ablation modes, offering unmatched versatility compared to traditional stripping techniques.

Applications Across Industries

Aerospace and Military Wiring

High-reliability harnesses use laser cutting for PTFE and Kapton insulation, allowing operators to peel insulation cleanly without nicking conductors, essential for flight-critical systems.

Medical Devices and Microelectronics

UV laser ablation provides sterile, debris-free removal for ultra-fine wires used in catheters, pacemakers, and sensors. The non-contact nature prevents contamination.

Automotive and High-Voltage Cables

Laser scoring is preferred for thick multi-layer cables, where complete vaporization would be inefficient. Operators peel the outer jacket after laser cutting, exposing inner wires for termination.

Benefits of Laser Wire Cutting and Ablation

-

Dual functionality: cut or vaporize based on material needs.

-

Damage-free operation on sensitive conductors.

-

Repeatable precision even on micro-scale wires.

-

Cleaner results than mechanical stripping.

-

Reduced maintenance and no consumables.

Challenges and Considerations

While laser systems deliver remarkable precision, they also introduce a high initial investment – higher than traditional tools. Despite this, long-term savings and process reliability make laser systems the preferred industrial solution.

Safety Protocols for Laser Wire Stripping and Cutting

Fume Extraction and Debris Management

Even in cutting mode, some materials release particulates or vapors. Fume extraction systems ensure a clean and safe workspace. Laser Wire Solutions systems are sold with extractions unless customers use their own factory-installed extraction system.

FAQs About Laser Wire Stripping and Cutting

1. Do all insulation materials vaporize when exposed to lasers?

No. Some materials, especially thick or composite coatings, resist vaporization or would be very slow. In such cases, the laser cuts or scores the insulation so that it can be peeled off cleanly and quickly.

2. How does cutting differ from ablation in laser stripping?

Ablation removes the insulation entirely by vaporizing it, while cutting creates defined edges or scores that let the operator manually remove the insulation.

3. Can a single laser perform both cutting and ablation?

Yes. Many modern systems allow switching between continuous-wave cutting and pulsed ablation, adapting automatically based on insulation type.

4. Does cutting increase the risk of conductor damage?

No, provided the laser is properly calibrated. Cutting parameters are designed to penetrate the insulation layer only, the laser beam reflects from the conductors or metal shielding.

The Dual Power of Laser Precision

The ability to strip wire insulation without touching the conductor has transformed modern manufacturing. Whether through direct ablation or precision cutting for peeling, lasers offer unmatched control, safety, and repeatability.

This hybrid approach—combining laser scoring, cutting, and ablation—ensures compatibility with virtually any insulation type. It’s cleaner, faster, and far more reliable than traditional stripping methods, positioning laser technology as the future standard of precision wire processing.