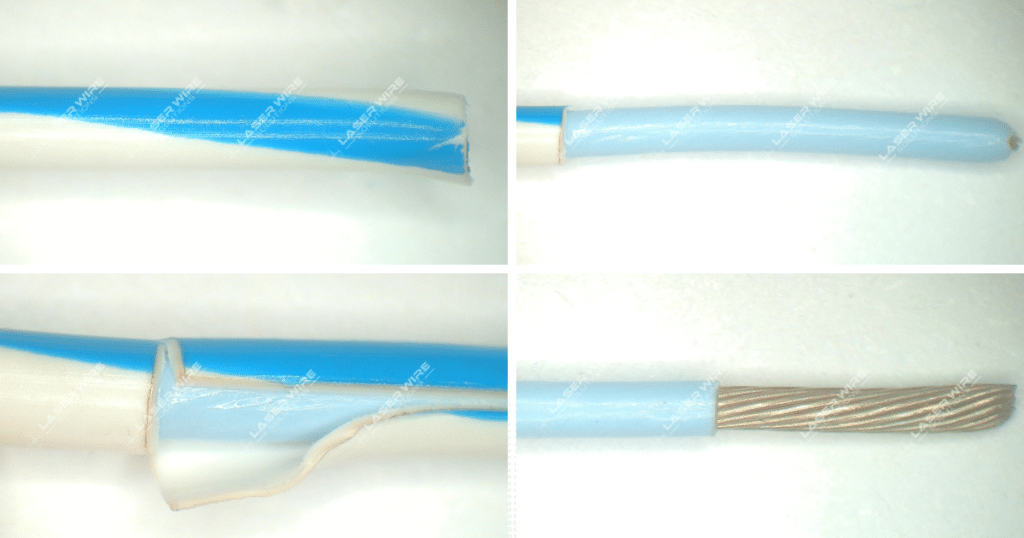

Stripping polymer-on-polymer wire constructions poses a unique challenge—especially when both layers are chemically and visually similar. In this case, the customer needed to expose an inner blue insulation layer while preserving it completely, as it forms part of a critical dual-stage crimp (onto conductor and insulation) for environmental sealing.

Application Overview

-

Wire construction: White outer polymer jacket over a blue inner polymer

-

Required process: Remove white jacket cleanly, expose blue layer undamaged

-

Target strip length: 5–10 mm

-

Machine used: Mercury-4, 30W configuration

Laser Process Optimization

Using the Mercury-4’s high-speed galvo system, we fine-tuned cross-cut and slit parameters for partial-depth cutting. This technique allowed the outer jacket to be snapped off manually, revealing the inner layer intact.

Key parameters:

-

~2.3 seconds per cycle (cross-cut + slit)

-

Positional accuracy: ±0.10 mm

-

Multiple power and speed combinations tested to reach optimal outcome

Results

✔ Clean and repeatable cut through the outer layer

✔ Inner insulation fully preserved, meeting crimping and ingress protection standards

✔ Slug removal possible by hand

✔ Future improvement expected with fixture and software tuning (~15–20% cycle time reduction)

Competitive Advantage

This type of dual-layer precision strip is generally believed to be unachievable with laser—but the Mercury-4 proves otherwise. Its flexibility and fine control provide a significant edge over competitors when dealing with sensitive multi-stage assemblies.

Laser Wire Solutions continues to push the frontier of what’s possible in laser wire stripping. If your application demands precision, reliability, and innovation—get in touch.