Wearable technology is rapidly expanding across industries that include consumer electronics, healthcare, sports performance, vision technology, and advanced textiles. Behind every small wearable device is a network of ultra thin wires that carry power, data, and sensor readings. To prepare these wires safely and accurately, manufacturers rely on laser wire stripping for wires in wearable devices, a technique that creates clean and consistent insulation removal without direct contact.

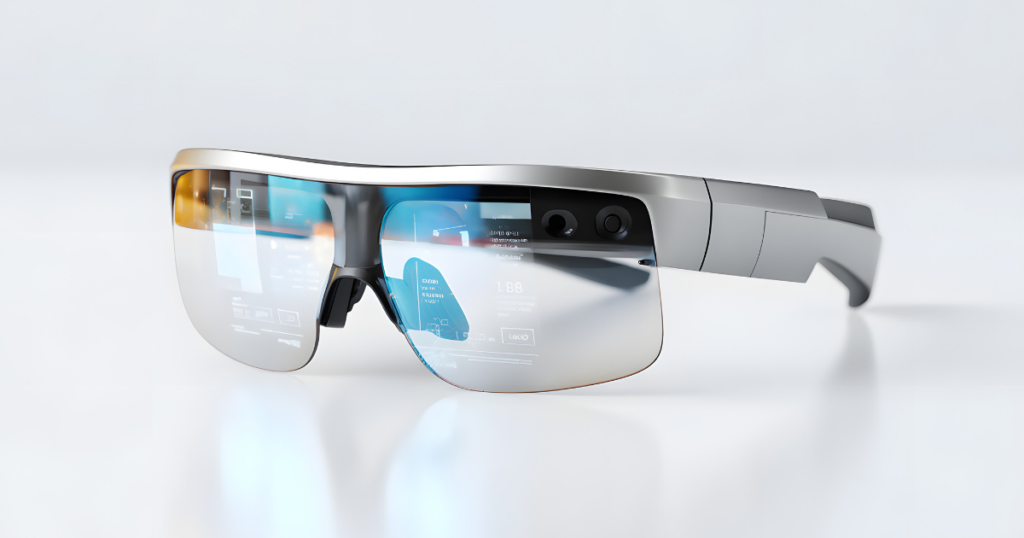

This method is ideal for modern consumer wearables such as smart glasses, smart rings, fitness trackers, AR or VR headsets, and hearables. It is equally effective for medical wearables like ECG sensors and glucose monitors where accuracy is mission critical. In this article, we explore how the technology works, its advantages, and why it has become essential for the next generation of wearables.

Introduction to Laser Wire Stripping Technology

What Laser Wire Stripping Means

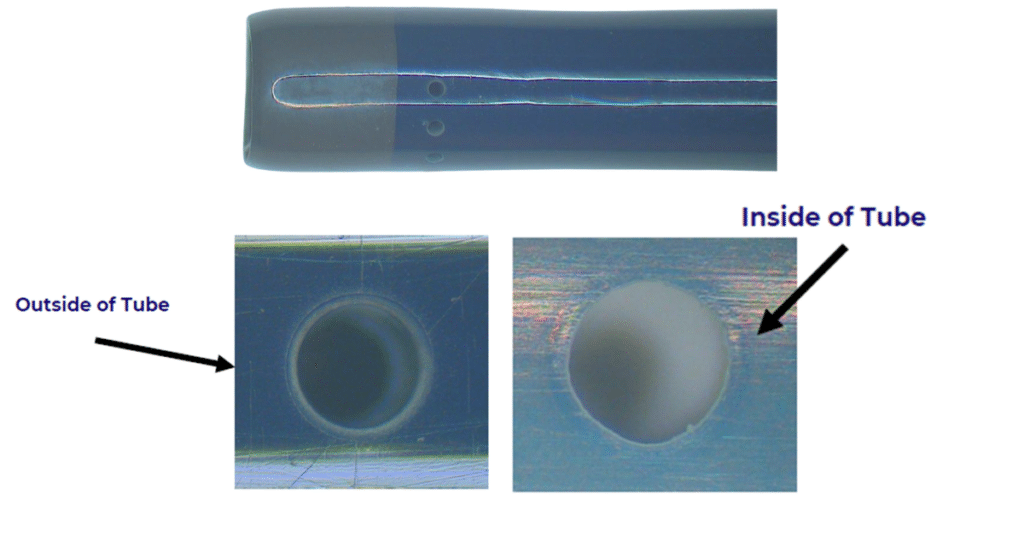

Laser wire stripping is a non contact process that uses controlled laser energy to remove insulation from electrical wires. Instead of pulling or cutting insulation with blades, the laser vaporizes the coating without touching the conductor.

How Laser Energy Removes Insulation

The laser wavelength is selected so that the insulation absorbs the energy while the conductor reflects it. This creates a highly controlled ablation effect that leaves the metal core smooth, shiny, and completely undamaged.

Why Wearable Devices Need Highly Accurate Wire Processing

Increasing Miniaturization of Wearables

Wearable devices are getting smaller every year. Smart rings, smart glasses, smart earbuds, and micro medical sensors use wires that can be thinner than human hair. These tiny wires cannot tolerate the physical stress of mechanical or manual stripping tools.

Reliability Requirements in Consumer and Medical Wearables

Wearables must work during constant movement, bending, sweat exposure, and daily wear. Clean insulation removal helps ensure:

-

stable signal transmission

-

accurate biometric readings

-

long device lifespan

-

safe electrical performance

Key Benefits of Laser Wire Stripping for Wearables

Precise, Contact Free Wire Processing

Laser energy removes material without ever touching the wire. This prevents conductor nicks, stretching, or deformation, which are common risks in mechanical or manual stripping.

Repeatable Accuracy for Mass Production

Lasers deliver micron accuracy on every strip, ideal for high volume manufacturing of smart rings, AR modules, VR sensors, and medical devices.

Safe for Sensitive and Flexible Materials

Laser settings can be tuned for materials including:

-

TPU

-

silicone

-

PTFE

-

polyimide

-

PFA and FEP

This compatibility is essential in flexible wearables and textile based electronics.

Types of Lasers Used for Micro Wire Stripping

CO2 Lasers

Useful for thicker insulation and general purpose removal.

UV Lasers

Popular for ultra fine wires because they offer high absorption and low heat impact.

Fiber Lasers

Known for high speed, efficiency, and excellent beam control.

Wire Materials Used in Modern Wearable Devices

Copper and Tinned Copper Wires

These are widely used because they offer strong conductivity and flexibility.

Micro Coaxial Wires

AR and VR headsets, smart glasses, and medical wearables use micro coaxial cables for high speed data signals and low noise.

Flexible Litz Wires

Ideal for movement heavy applications such as smart clothing and soft robotics.

Insulation Types That Work Well With Laser Stripping

Polyimide

A favorite for high temperature electronics.

PTFE, PFA, FEP

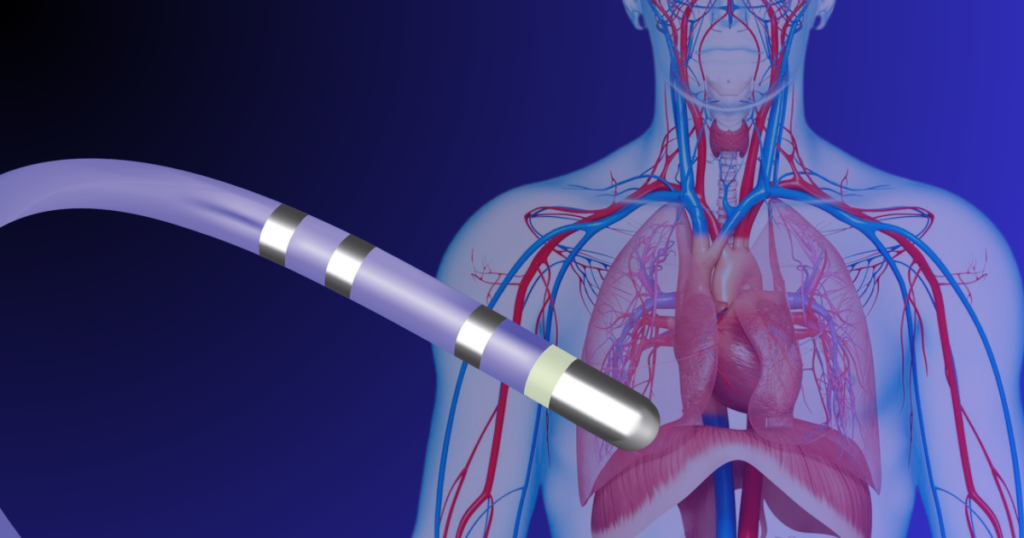

Fluoropolymers are common in medical devices because they resist chemicals and moisture.

Silicone and TPU

Found in flexible audio wearables, smart rings, and body worn sensors.

Applications of Laser Wire Stripping Across Wearable Technologies

Smart Glasses and AR or VR Headsets

Wires for displays, cameras, gesture sensors, and micro batteries require precise stripping to prevent signal interference.

Smart Rings and Miniature Gesture Devices

Smart rings contain some of the smallest wearable wire assemblies. Laser stripping ensures perfect preparation for ultra compact components.

Smartwatches and Fitness Trackers

Used for heart rate sensors, battery connections, antenna leads, and haptic motors.

Hearables and Audio Wearables

True wireless earbuds and health focused hearables depend on tiny balanced armature drivers and biometric sensors that require high quality wire stripping.

Medical Wearables and Biometric Sensors

Laser processed wires are used in glucose monitors, ECG patches, EMG sensors, and respiratory monitors.

Smart Clothing and E Textiles

Flexible wires woven into fabrics must undergo clean stripping to maintain comfort and durability.

Laser vs Mechanical or Manual Wire Stripping

Conductor Safety and Damage Prevention

Mechanical tools or manual processes introduce a risk of scraping the conductor; particularly if relying on operator skill. Laser processing eliminates this risk because it is fully contact free.

Speed, Cost, and Yield Considerations

Although the initial equipment cost for lasers is higher, the long term savings from higher yield and fewer defects make lasers a cost effective solution.

Compliance and Quality Standards in Wearable Manufacturing

IPC WHMA 620 Standards

Defines acceptable quality levels for wire preparation, soldering, and connections.

ISO and FDA Requirements for Medical Wearables

Medical grade devices must meet strict levels of accuracy and cleanliness. Laser stripping supports these compliance goals by reducing production defects.

Future of Laser Wire Processing in Wearables

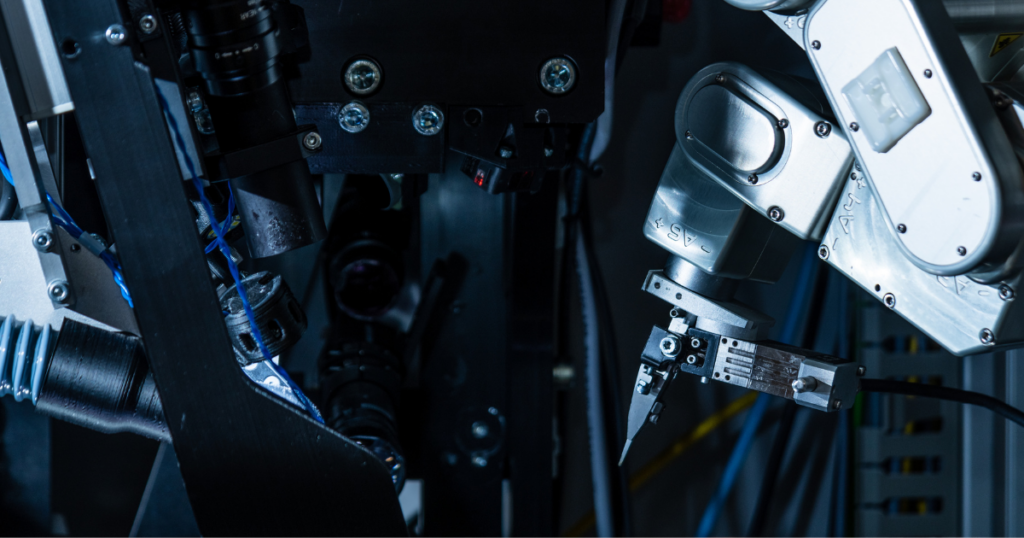

AI Enabled Automation

Factories are adopting automated systems that use AI to control stripping accuracy and adjust settings in real time.

Advancements in Short Pulse and Femto Lasers

Shorter pulse lasers reduce heat impact even further, making them ideal for future miniaturized wearables.

Frequently Asked Questions

1. Can lasers strip the tiny wires used in smart rings and smart glasses

Yes. UV lasers can process wires far smaller than what mechanical tools can safely handle.

2. Do lasers damage the metal conductor

No. The correct wavelength removes insulation while leaving the conductor completely intact.

3. What types of wearables benefit most from laser wire stripping

Smart glasses, smart rings, fitness trackers, AR headsets, medical wearables, earbuds, and e textile systems.

4. Is laser stripping faster than manual or mechanical methods

Yes. Semi and fully automated laser systems offer high speed and consistent throughput.

5. Are lasers safe for medical grade wire materials

Yes. Lasers can cleanly remove insulation from polyimide, PTFE, and other medical grade coatings.

6. What is the main advantage of laser wire stripping for mass production

Repeatable accuracy that reduces scrap and ensures consistent quality across thousands of wires.

Conclusion

Laser wire stripping for wires in wearable devices plays a vital role in manufacturing modern technologies such as smart glasses, smart rings, smartwatches, hearables, AR systems, and medical sensors. The method provides unmatched accuracy, contact free safety, and reliable results that support both consumer and medical grade performance. As wearable devices continue to shrink and evolve, laser processing will remain one of the most essential manufacturing techniques in the industry.

If you’d like to discuss your project with the experts in laser wire stripping, click here.