Introduction to Automotive Wire Stripping Challenges

Electric vehicles (EVs) are transforming the automotive industry, but they also introduce a new level of complexity, especially in wiring systems. These vehicles use a dense mix of high-voltage and low-voltage wires, requiring precise insulation removal during manufacturing. Mistakes in wire stripping can lead to performance loss, safety hazards, or system failures.

Traditional wire stripping methods, like mechanical blades, struggle with the precision and consistency required for automotive applications. As demand for zero-defect production grows, laser wire stripping has emerged as the preferred alternative.

Understanding Blade Wire Stripping Methods

Mechanical blade stripping uses physical tools to cut and remove insulation from wires. This method is simple but often falls short in applications demanding extreme accuracy.

Common Tools Used in Blade Stripping

-

Manual wire strippers

-

Rotary or pneumatic strippers

-

Semi-automated machines with mechanical dies

Typical Processes and Limitations

-

Manual depth setting is error-prone

-

Blade wear leads to inconsistent results

-

Poor adaptation to varying insulation types

-

High risk of conductor damage

Common Issues with Blade Stripping in EVs

Automotive manufacturers have reported several challenges with mechanical blade stripping:

Wire Nicking and Conductor Damage

Even minimal blade penetration beyond the insulation can cause:

-

Reduced electrical efficiency

-

Increased failure rates under load

-

Long-term reliability issues

Inconsistent Insulation Removal

Inaccurate or uneven stripping causes:

-

Weak solder or crimp joints

-

Poor electrical continuity

-

More frequent rework and inspection

Safety Hazards

Mechanical tools pose operational safety risks and can introduce debris into sensitive assemblies—resulting in added cleaning and post-processing steps.

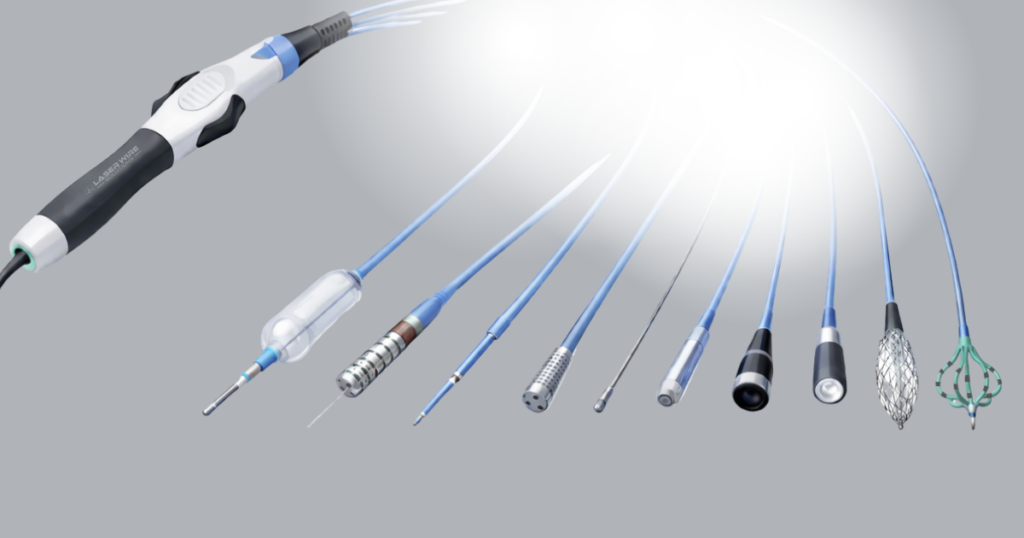

What Is Laser Wire Stripping?

Laser wire stripping uses focused laser energy to vaporize insulation with extreme precision, leaving the conductor untouched.

How It Differs from Traditional Methods

-

Contactless processing – no mechanical friction

-

Software-driven precision – depth, pattern, and location are fully programmable

-

Material versatility – works with a variety of insulation types, including difficult-to-strip materials

Key Advantages of Laser Wire Stripping for Automotive Manufacturing

Laser wire stripping offers consistent, repeatable performance that meets the quality standards of modern automotive production.

Precision and Repeatability

-

Micron-level control of stripping depth

-

Reliable stripping on wires as thin as 32 AWG

-

Eliminates variation from tool wear or manual settings

Zero-Contact Processing

-

No pressure or stress on the conductor

-

Ideal for fragile or micro-miniature wires

-

Reduces the chance of insulation melting or deformation

Multi-Conductor and Shielded Cable Compatibility

-

Window, full, or partial strips with minimal setup

-

Protects shielding and inner conductors during stripping

Compatibility with Automotive Materials

Laser stripping is effective on insulation materials common in vehicle manufacturing, including:

-

Teflon (PTFE)

-

Kapton (Polyimide)

-

Cross-linked Polyethylene (XLPE)

-

Silicone and PVC

Each of these materials requires precise energy control—something lasers manage easily and without physical contact.

Cost Comparison: Laser vs. Blade Stripping

While lasers involve a higher initial investment, they reduce operational costs significantly.

| Factor | Blade Stripping | Laser Stripping |

|---|---|---|

| Initial Equipment Cost | Low | High |

| Maintenance Requirements | Frequent (blades, dies) | Minimal (optics cleaning) |

| Operator Dependency | High | Low |

| Quality Variability | Moderate to High | Minimal |

| Rework/Scrap Costs | High | Low |

Laser systems support long-term process reliability—an essential requirement for Six Sigma-aligned operations.

Automation and Integration with Automotive Production Lines

Modern automotive manufacturing relies on automation, data logging, and consistent throughput. Laser wire strippers are built for this.

Smart Manufacturing Compatibility

-

Easily integrated into robotic assembly lines

-

Software-controlled patterns and motion profiles

-

Data export for quality tracking and documentation

Six Sigma and Lean Integration

Laser stripping contributes directly to Six Sigma goals:

-

Lower process variation (σ)

-

Fewer defects per million opportunities (DPMO)

-

Improved process capability (Cp, Cpk)

This technology empowers manufacturers to maintain high throughput without compromising on quality.

Safety and Quality Assurance with Laser Systems

Laser stripping enhances safety and improves manufacturing outcomes by:

-

Preventing accidental conductor contact

-

Eliminating mechanical wear and variability

-

Supporting consistent output essential for Six Sigma certification

This approach simplifies root cause analysis and continuous improvement processes within quality management systems.

Real-World Case Studies

Leading automotive manufacturers globally have adopted laser stripping to improve quality control and reduce rework. Benefits reported include:

-

Elimination of conductor damage

-

Faster assembly line throughput

-

Improved performance metrics aligned with Six Sigma goals

These outcomes have made laser stripping a standard in advanced EV production environments.

Limitations of Laser Wire Stripping

Despite its benefits, laser stripping may not be the best fit for every scenario:

-

High Initial Cost: Budget may be a concern for small-scale operations

-

Learning Curve: Technicians must be trained on laser safety and operation

-

Material Constraints: Some highly reflective or foamed insulations may require specialized laser types

However, for companies prioritizing long-term reliability, quality control, and scalability, the advantages typically outweigh the limitations.

Choosing the Right Wire Stripping Method for Your Automotive Application

| Criteria | Blade Stripping | Laser Stripping |

|---|---|---|

| Conductor Damage Risk | High | None |

| Maintenance Frequency | High | Low |

| Process Automation | Limited | Fully compatible |

| Operator Skill Dependence | High | Low |

| Six Sigma Quality Support | Challenging | Highly compatible |

Laser stripping is the clear winner when product consistency and process stability are mission-critical.

Laser Stripping Technology Types

CO₂ Lasers

-

Best for transparent or light-colored insulations

-

Limited on dark materials or small wires

The right laser type depends on the specific application and insulation involved.

Maintenance and Lifespan of Laser Machines

Laser wire strippers are designed for industrial uptime:

-

Few moving parts = reduced mechanical wear

-

Optics cleaning = periodic but simple

-

Software updates = often cloud-enabled

This makes them a smart investment for operations applying Six Sigma and Lean Manufacturing frameworks.

Regulatory and Quality Standards in EV Wiring

Laser stripping supports compliance with global standards:

-

IPC/WHMA-A-620: Acceptability for wire harness assemblies

-

ISO/TS 16949: Automotive sector quality systems

-

SAE and OEM-specific criteria

Laser systems allow better traceability, which is critical during audits and compliance reviews.

Future of Wire Stripping in Automotive Industry

As EVs evolve, wire density increases, and insulation materials become more advanced. Laser systems are ready to meet the challenge.

Emerging Trends

-

Smaller wire gauges

-

Flexible printed cables (FPCs)

-

AI-optimized stripping patterns

-

Increased need for zero-defect performance

Laser technology will remain central to Six Sigma-aligned, defect-reducing manufacturing systems.

FAQs

1. Is laser wire stripping safe for high-voltage EV cables?

Yes. Laser technology removes insulation without contacting the conductor, preserving cable integrity.

2. Does laser stripping support Six Sigma standards?

Absolutely. Its precision and repeatability help meet low DPMO and high Cpk process standards.

3. Can laser systems handle all insulation types?

Most common EV materials, including Kapton and XLPE, are compatible. Specialized lasers can handle even more.

4. Is laser stripping cost-effective long term?

Yes. Reduced scrap, downtime, and rework make it highly cost-effective over time.

5. What kind of training is needed for laser stripping?

Basic laser safety and system operation training is usually sufficient. Most interfaces are user-friendly.

6. Can I integrate laser stripping into an automated line?

Yes. Laser systems are designed for seamless integration into automated, data-driven EV production environments.

Conclusion

Laser wire stripping is more than a modern upgrade—it’s a critical shift in how EV manufacturers meet the demands of speed, precision, and quality. As companies embrace Six Sigma and strive for continuous improvement, laser systems stand out for their consistency, reliability, and adaptability. Whether you’re building EVs today or preparing for the future, it’s time to leave the blades behind and aim for precision with light.