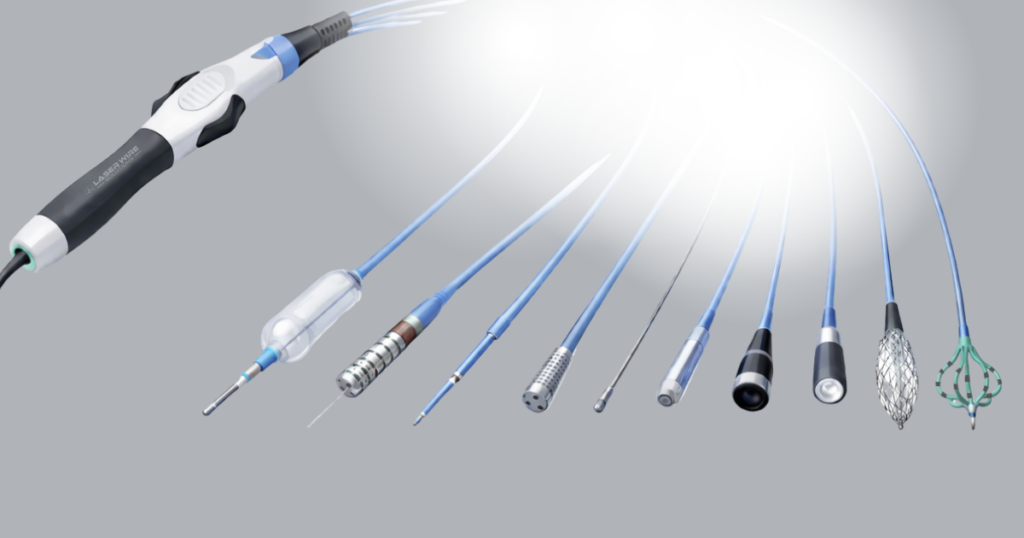

How do you manufacture a catheter that is small enough to navigate the human vascular system, flexible enough to bend without failure, and precise enough to perform reliably inside the body, millions of times over?

We understand catheter manufacturing, precision is not a differentiator; it is a requirement. Devices used in cardiovascular, neurovascular, and minimally invasive procedures must meet extreme dimensional tolerances while remaining biocompatible, durable, and fully traceable. Even minor variability can compromise performance, patient safety, or regulatory approval.

Laser technology has fundamentally transformed how these devices are designed and produced. From processing ultra-fine wires to shaping complex hypotubes and assembling finished devices, lasers deliver a level of accuracy, repeatability, and process control that conventional mechanical methods cannot match.

Laser Technology in Medical Device Manufacturing

Several laser technologies are commonly used in catheter manufacturing, each selected for its specific interaction with materials and feature requirements.

Typical laser systems include:

-

Fiber lasers for precision cutting and stripping of metals and fine wires

-

Femtosecond lasers for ultra-low thermal impact micro-machining

-

UV lasers for polymer processing and cold ablation

The choice of laser depends on material type, wall thickness, feature size, and thermal sensitivity.

Key Advantages of Lasers in Catheter Production

Laser processing offers a unique combination of benefits that align perfectly with medical manufacturing requirements:

-

Non-contact processing – eliminates mechanical stress and tool-induced deformation

-

Micron-level precision – essential for miniature and high-density components

-

Exceptional repeatability – critical for validated, high-volume production

-

Material versatility – suitable for metals, polymers, and multi-layer composites

Because catheters often combine metal shafts, polymer coatings, and embedded conductors, lasers provide the flexibility needed to process complex, multi-material assemblies with confidence.

Laser Wire Processing: The Foundation of Precision

Wire processing is one of the earliest and most critical stages in catheter manufacturing. Guidewires, reinforcement coils, pull wires, and sensor conductors form the functional backbone of many catheter designs.

Laser Cutting of Ultra-Fine Wires

Lasers can cut wires thinner than a human hair with clean, burr-free edges and exceptional dimensional consistency. Unlike mechanical cutting methods, laser cutting does not crush, stretch, or deform the wire.

This preserves:

-

Diameter consistency

-

Tensile strength

-

Electrical and mechanical performance

For high-performance catheters, this consistency is essential.

Laser Stripping and Ablation

In multi-layer or insulated wires, lasers precisely remove polymer insulation without damaging the underlying conductor. This is particularly important in electrophysiology, neuro, and “smart” catheters where signal integrity is critical.

Laser stripping enables:

-

Precise strip lengths

-

Clean transitions between materials

-

Minimal thermal impact when properly tuned

Why Lasers Outperform Traditional Wire Processing Methods

Compared to blades or mechanical stripping systems, lasers offer:

-

No tool wear or degradation

-

No physical contact with the wire

-

Minimal and controllable heat-affected zones

The result is higher yield, lower scrap, and more reliable downstream assembly.

Laser Cutting of Hypotubes for Catheter Shafts

Hypotubes – thin-walled metal tubes – are widely used to form catheter shafts. Their performance depends on carefully engineered cut patterns that balance flexibility, torque transmission, and pushability.

Complex Geometry with Extreme Accuracy

Laser cutting enables intricate hypotube designs, including:

-

Variable stiffness zones

-

Spiral and lattice patterns

-

Customized flexibility profiles along the shaft length

These geometries would be extremely difficult, or impossible, to produce consistently using conventional machining.

Common Hypotube Materials

Lasers are routinely used to process:

-

Stainless steel

-

Nitinol

-

Cobalt-chromium alloys

Laser cutting preserves the mechanical properties of these materials while delivering precise, repeatable results, essential for navigating complex vascular anatomy.

Laser Drilling and Micro-Feature Creation

Many catheter designs require micro-holes or perforations for fluid delivery, sensing, or drug elution. Laser drilling provides unmatched control over feature size, placement, and consistency.

Typical Applications

-

Side holes for infusion catheters

-

Sensor ports in diagnostic devices

-

Micro-perforations for controlled drug release

Laser-drilled features have smooth edges and consistent diameters, reducing turbulence, improving flow characteristics, and enhancing clinical performance.

Laser Welding and Joining of Catheter Components

Once individual components are prepared, they must be joined into a complete device. Laser welding is widely used for assembling catheter components due to its precision and reliability.

Benefits of Laser Welding

-

Highly localized heat input

-

Strong, repeatable welds

-

Minimal distortion of surrounding materials

This is especially valuable when joining dissimilar materials, such as metal hypotubes, fine wires, and marker bands.

Laser Marking for Traceability and Regulatory Compliance

Medical device regulations require full traceability throughout the product lifecycle. Laser marking provides permanent, high-contrast identification without inks, chemicals, or consumables.

Common Laser Markings

-

Lot and serial numbers

-

Device identifiers

-

Depth and positioning markers on catheter shafts

Laser markings remain legible after cleaning, sterilization, and clinical use, supporting long-term compliance and patient safety.

Laser Processing of Polymers and Coatings

Beyond metals, lasers play a critical role in processing polymer components and coatings used in catheter manufacturing. Many modern catheter designs rely on multi-layer polymers and miniature polymer features that demand extremely precise, low-impact processing.

Because lasers operate without physical contact and can be focused to a small spot, they enable controlled material removal while minimizing the risk of mechanical damage, deformation, or contamination.

Typical Applications

-

Selective removal of polymer layers

Precisely stripping or ablating outer coatings to expose underlying structures without damaging conductive or structural elements. -

Precision trimming of catheter tips

Achieving clean, repeatable tip geometries that support smooth insertion, accurate placement, and consistent clinical performance. -

Micro-component cutting and profiling

Cutting ultra-small polymer components and features – such as thin rings, spacers, or other micro-geometries – used within catheter assemblies. Laser cutting allows these components to be produced with tight tolerances and high repeatability, even at very small scales. -

Surface texturing to improve bonding or adhesion

Creating controlled surface features that enhance adhesion between polymers or between polymer and metal components during assembly.

Laser processing produces clean edges and highly controlled material removal, significantly reducing the risk of particulates, defects, and rework, key advantages in regulated medical manufacturing environments.

Quality Control and Inspection Enabled by Lasers

Laser-based measurement and inspection systems are often integrated directly into production lines, enabling real-time quality control.

Key Inspection Capabilities

-

Diameter and concentricity measurement

-

Cut pattern and feature verification

-

Alignment and positioning checks

This closed-loop approach ensures every catheter meets specification before final assembly and packaging.

FAQs About Laser-Based Catheter Manufacturing

Why are lasers preferred over mechanical tools in catheter manufacturing?

Lasers provide non-contact, ultra-precise, and highly repeatable processing – ideal for miniature, high-risk medical devices.

Can lasers process both metal and polymer catheter components?

Yes. Modern laser systems are highly versatile and can process metals, polymers, and composite structures with excellent control.

Does laser processing damage delicate materials?

When correctly configured, lasers create minimal heat-affected zones, preserving material integrity.

Are laser-manufactured catheters safer for patients?

Higher precision and consistency reduce defects, directly supporting device reliability and patient safety.

How do lasers support regulatory compliance?

Laser marking and in-line inspection improve traceability, documentation, and process control.

Is laser catheter manufacturing cost-effective?

While initial investment is higher, improved yields, reduced scrap, and faster processing deliver strong long-term ROI.

The Future of Precision Catheter Manufacturing

From wire processing to finished devices, laser technology has become the backbone of modern catheter manufacturing. It enables levels of precision, repeatability, and design freedom that directly impact clinical performance and patient outcomes.

As catheters continue to become smaller, smarter, and more complex, lasers will remain central to their manufacture, supporting innovation while reducing risk in one of the most demanding industries in the world.