In an era where businesses are increasingly under scrutiny for their environmental practices, adopting sustainable technologies is not just a moral imperative but also a sound financial decision.

Laser wire stripping technology stands out as a prime example of an innovation that not only reduces environmental impact but also maximizes profitability.

In this article, we will explore the dual benefits of laser wire stripping, shedding light on its positive environmental and economic effects.

Reducing Waste, Boosting Sustainability

-

Laser Precision

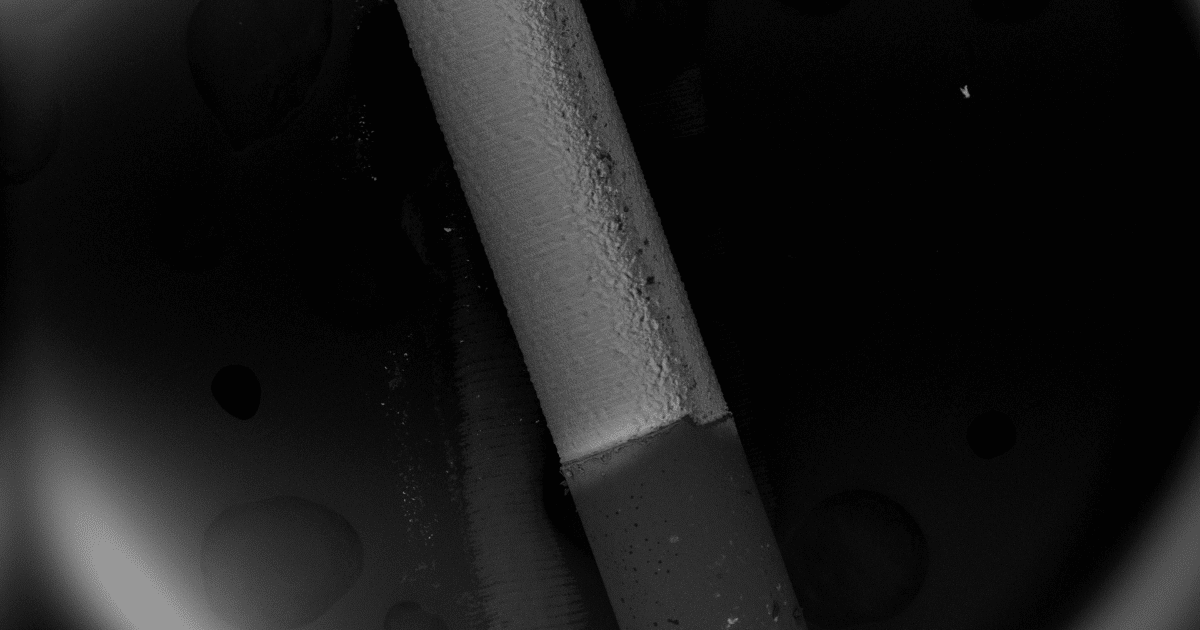

Laser wire stripping employs advanced technology to precisely remove insulation from wires without generating waste. Unlike traditional methods such as mechanical stripping or chemical processes, laser technology ensures minimal material loss.

Precision is the name of the game, as lasers can target specific areas, leaving the rest of the material untouched. This accuracy significantly reduces the amount of scrap generated during the wire-stripping process.

-

Material Efficiency

By minimizing waste, laser wire stripping contributes to a more sustainable use of resources. The reduction in material consumption not only conserves valuable resources but also alleviates the environmental burden associated with the disposal of excess waste.

Businesses embracing this technology can proudly communicate their commitment to sustainable practices, enhancing their reputation in an eco-conscious market.

Maximizing Profits through Efficiency

-

Increased Throughput

Laser wire stripping is not only about environmental responsibility; it is a smart business strategy. The precision and speed of laser technology translate into increased throughput.

Businesses can process wires more quickly and efficiently, leading to a boost in overall productivity. This enhanced efficiency directly correlates with cost savings and improved profitability.

-

Energy-Efficient Operations

Beyond waste reduction, laser wire stripping technology aligns with energy-efficient practices. Compared to traditional wire-stripping methods, lasers consume less energy, contributing to a reduction in overall operational costs. This not only enhances a company’s bottom line but also positions it as an industry leader in sustainable energy practices.

A Smart Financial Decision

In conclusion, adopting laser wire stripping technology is not just an environmental choice; it is a strategic business decision. Businesses can align themselves with sustainable practices while simultaneously improving their financial health. The dual impact of waste reduction and increased profitability positions laser wire stripping as a forward-thinking solution for companies looking to thrive in a world that values both economic success and environmental responsibility. Embrace the future of wire stripping – minimize waste, maximize profits.