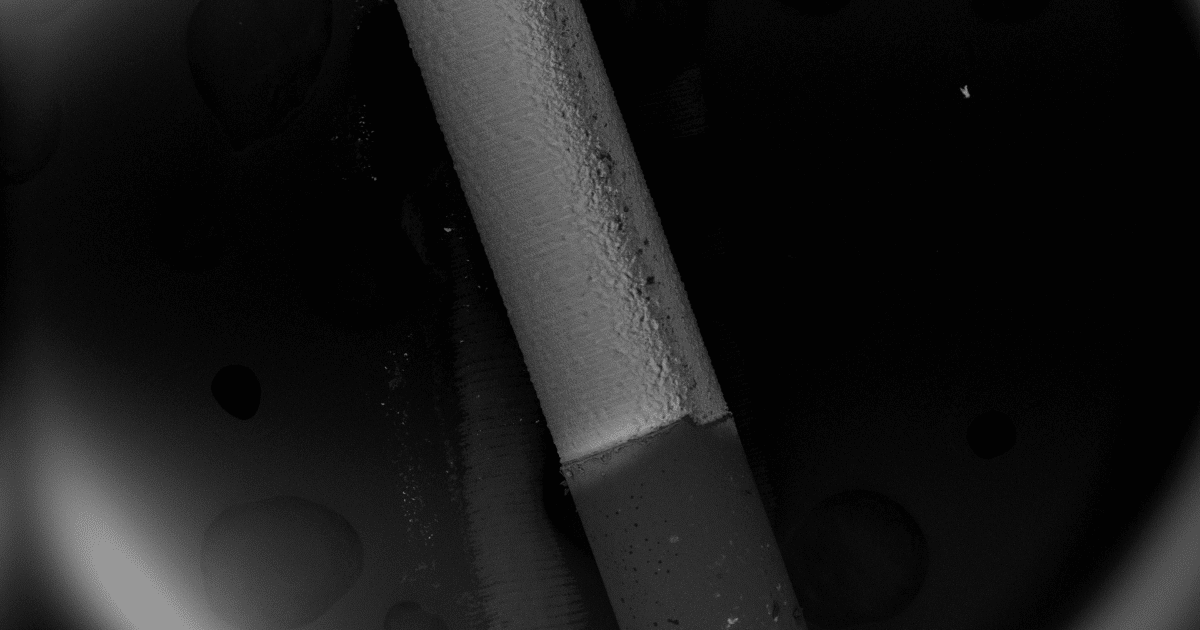

A leading medical device manufacturer, specializing in the production of medical mandrels and hypodermic tubes coated in PTFE, approached Laser Wire Solutions with a keen interest in exploring the potential of laser ablation technology.

The customer’s primary concern was the need to precisely strip sections of PTFE material with no residue, coupled with a rigorous quality checking process for each item to uphold the highest standards in medical device manufacturing.

Solution Identification

Laser Wire Solutions’ team of wire experts swiftly engaged with the customer to understand their unique requirements.

Following a thorough assessment, our experts recommended the Odyssey-4e, a state-of-the-art laser wire stripping machine specifically designed to cater to the materials used in medical devices and the varied sizes of wires involved. The Odyssey-4e, equipped with an optional quality check camera, perfectly aligned with the customer’s demands, offering a larger processing area for their specific wire type.

Demonstration of Capabilities

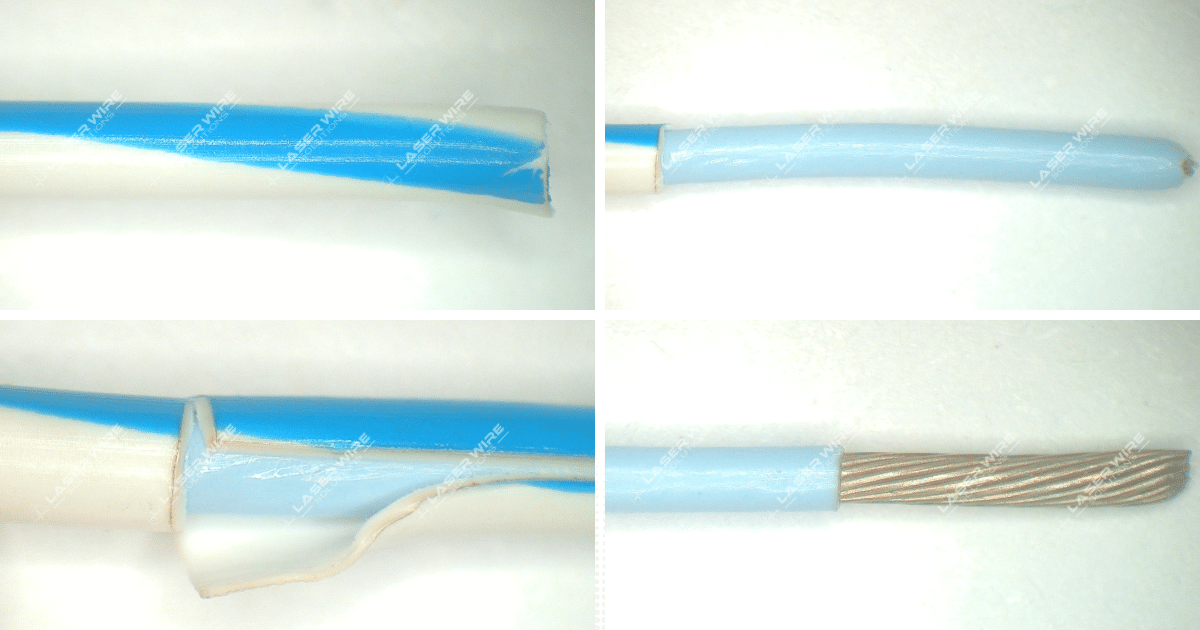

To showcase the effectiveness of our machinery, the customer was requested to provide a sample of their wire. Laser Wire Solutions processed the samples in-house using our cutting-edge technology and promptly returned them for evaluation. The results exceeded the customer’s expectations, setting the stage for further discussions and inquiries.

Refinement for Precision

In response to the customer’s queries and desire for even cleaner results, our wire experts collaborated closely with them.

We explained the customization capabilities of our machines, assuring the customer that recipes could be optimized to achieve the desired level of cleanliness.

The tailored recipe was then seamlessly integrated into the machine’s software to ensure consistent, high-quality results.

Decision and Investment

Impressed with the demonstrated capabilities and the adaptability of Laser Wire Solutions’ technology, the customer confidently proceeded with the capital investment in the Odyssey-4e.

The streamlined process from sample evaluation to customizing machine recipes instilled confidence in the customer, leading to a swift decision to integrate our innovative solution into their manufacturing workflow.

Implementation and Training

Following the order placement, the Odyssey-4e was built and delivered to the customer within a commendable six-week timeframe. Our dedicated team ensured a seamless setup process, and on-site training was arranged to empower the customer’s team with the knowledge required to maximize the machine’s potential.

This comprehensive approach ensured that the customer not only acquired cutting-edge technology but also had the expertise to maintain and operate the machinery optimally.

Conclusion

Laser Wire Solutions’ Odyssey-4e has proven to be a game-changer for our esteemed medical device manufacturing client.

Our commitment to understanding and addressing their unique needs, coupled with the demonstration of superior technology and unwavering support throughout the implementation phase, has solidified Laser Wire Solutions as the go-to partner for laser wire stripping in the medical device industry.

We invite other manufacturers handling similar wires to explore the transformative potential of our cutting-edge solutions, confident in the knowledge that Laser Wire Solutions stands as a beacon of innovation and reliability in laser wire stripping technology.