It is easy to ignore just how much of our world is made possible by wires.

Wires impact everyone’s lives. You will find them as components enabling high speed data transmission, or as the crucial component of a medical device such as a catheter, where it performs a function so critical that it saves lives. Each of these wires, irrespective of their application, requires some type of termination or process to expose the inner conductors.

Why Choose Laser Wire Stripping Over Conventional Methods?

Traditionally, exposing the inner conductors was completed using mechanical or chemical methods. In chemical processing, the wire is dipped in acids to burn away the outer coatings. Alternatively, mechanical methods require the use of brushes, pads or knives to reveal the inner wire. Although these techniques work, both methods have significant drawbacks that impact manufacturing processes. These include:

- Over processing – They remove the coating and continue into the inner metal.

- Process variability – The efficacy of chemicals and mechanical methods wanes with repeated use.

- Limited applications – Below a certain size, it becomes impossible to use traditional methods.

- Consumable items – Both methods need a constant supply of additional components to ensure manufacturing can continue.

Ultimately, these drawbacks lower product yield, raising the cost of manufacture. This can be through increased time, re-working of parts, or the constant requirement to replenish consumable items.

Laser technology, however, overcomes every one of these drawbacks.

Beginning in the 70s, lasers were applied in space programs to enable the use of thinner and lighter materials; this success was followed by expansion of the technique into military and then consumer electronics and medical devices.

The success of laser technology in wire stripping can be seen in how it resolves the issues found with the existing methods.

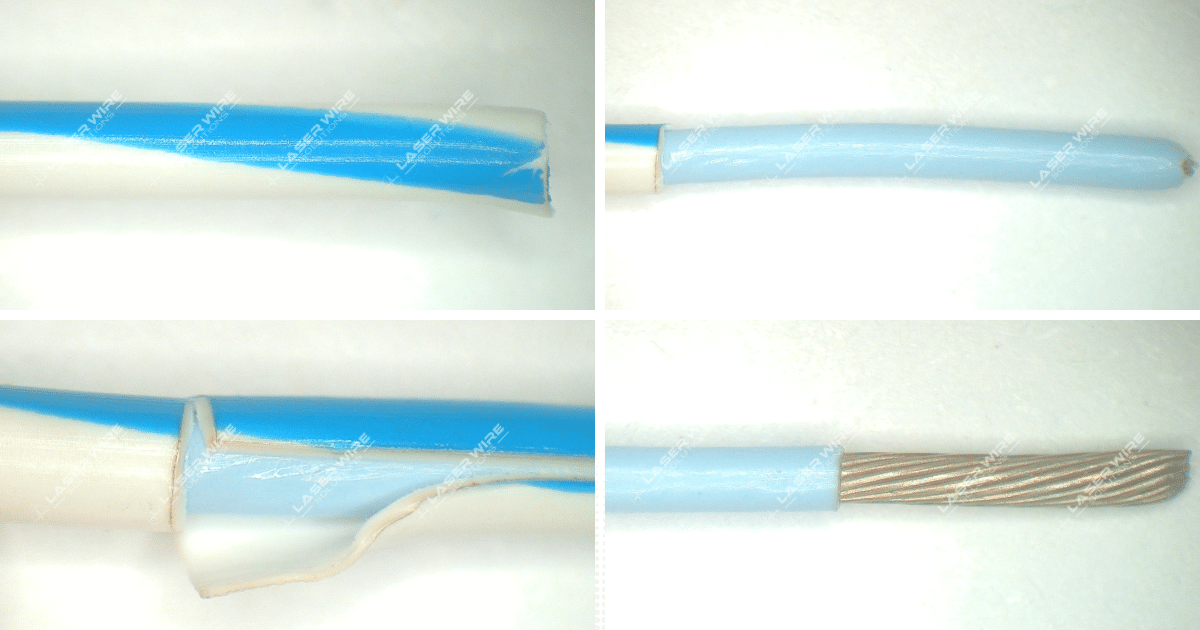

- Over processing – Through selecting the correct laser wavelength and optimizing the process window, the inner conductors can be exposed without damage.

- Process Variability – Unlike chemical and mechanical processes, the efficacy of laser processing does not reduce over time.

- Limited Applications – As the wire dimensions decrease, laser technology becomes the only viable and repeatable solution for processing ultra-fine wires.

- Consumable Items – The lifetime of lasers runs to tens of thousands of hours, eliminating the need for ongoing maintenance to ensure optimum performance.

This is only how it improves on the drawbacks of other methods. There are many further benefits from using this process.

What to Look for When Choosing a Laser Wire Stripper?

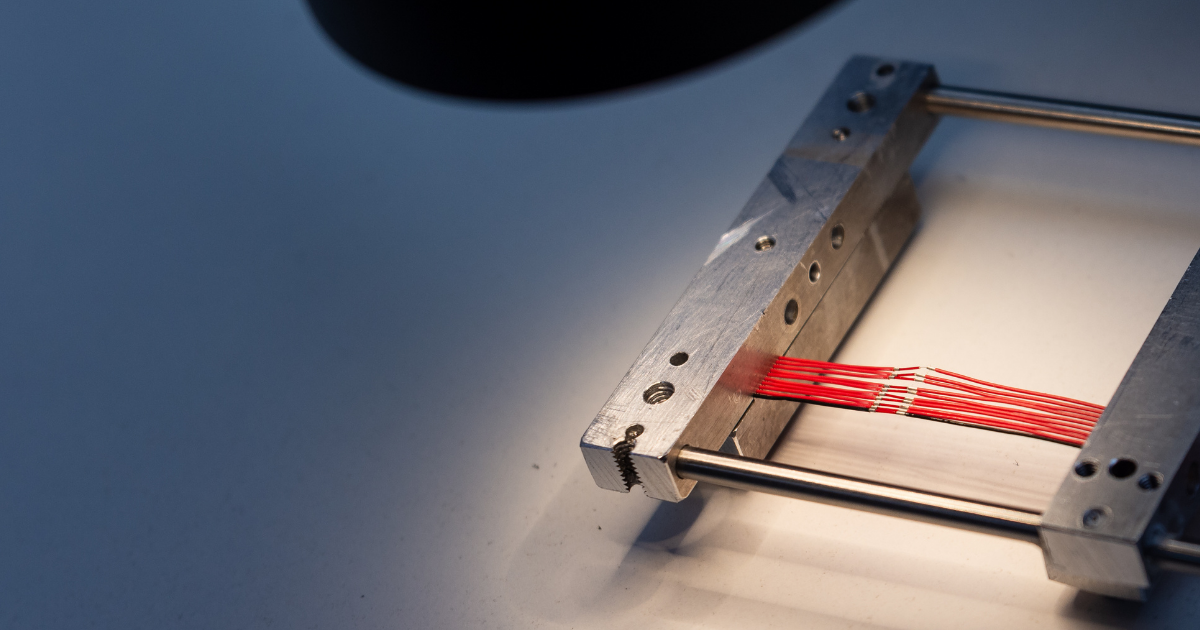

Laser wire stripping machines can process wires of different composition and diameter; by building this flexibility into the system design, a single system can provide a significant return on investment in a very short time.

Example 1 – Micro Coax

These complex wires require a bespoke solution for precision removal of the outer jacket, shield and dielectric insulator. Using our expertise, we have developed two solutions for processing these wires; one a semiautomated solution designed to fit into existing production lines, the other our Micro Coax Centre (MCC) which is a fully automated processing solution.

Example 2 – Catheter Wiring

Catheters are vital medical devices used globally to help people with heart conditions. These complex devices use enameled wires with dimensions at the micron scale (40 – >50AWG) making them impossible to process using traditional methods. Using our Odyssey wire stripping machines, we are not only able to remove the enamel coatings without damaging the conductor but our customer also reported a doubling of the force require to break the joint formed at later stages of the manufacturing process.

Since 2011, Laser Wire Solutions have been providing global companies with laser wire processing machines using our technology platforms developed in the United Kingdom. Our mission is to deliver solutions to our customers that break new ground in laser wire stripping technology, enabling our partnership to change the world, for the better, through innovation.