What is Laser Wire Stripping?

Laser wire stripping, or laser ablation, is a process that can be used to remove the outer coating of a wire or cable.

There are two different types of lasers: solid-state lasers and pulsed lasers. They differ in how they work, but both can be used for wire stripping.

Solid-state lasers use light to heat the target material, like the ones you see on your smartphone. Pulsed lasers heat the target material by sending pulses of light at it, like a laser pointer.

Solid-state lasers can cut or vaporize multiple materials at once. This is helpful when you need to separate your wires while removing insulation from both types of metals without damaging the conductor.

The Growth of Laser Wire Stripping

Laser wire stripping is often the preferred choice over conventional mechanical, chemical or manual wire stripping methods because of its numerous benefits.

For many cases, particularly those handling wires in the medical industry, laser wire stripping is the only viable solution as it intrinsically gives the high precision and unrivalled quality required to safely produce devices such as catheters.

As products and devices across all these industries become more micro, the methods to handling and stripping those wires becomes more delicate. There are a number of advantages to using laser technology for wire stripping. These include:

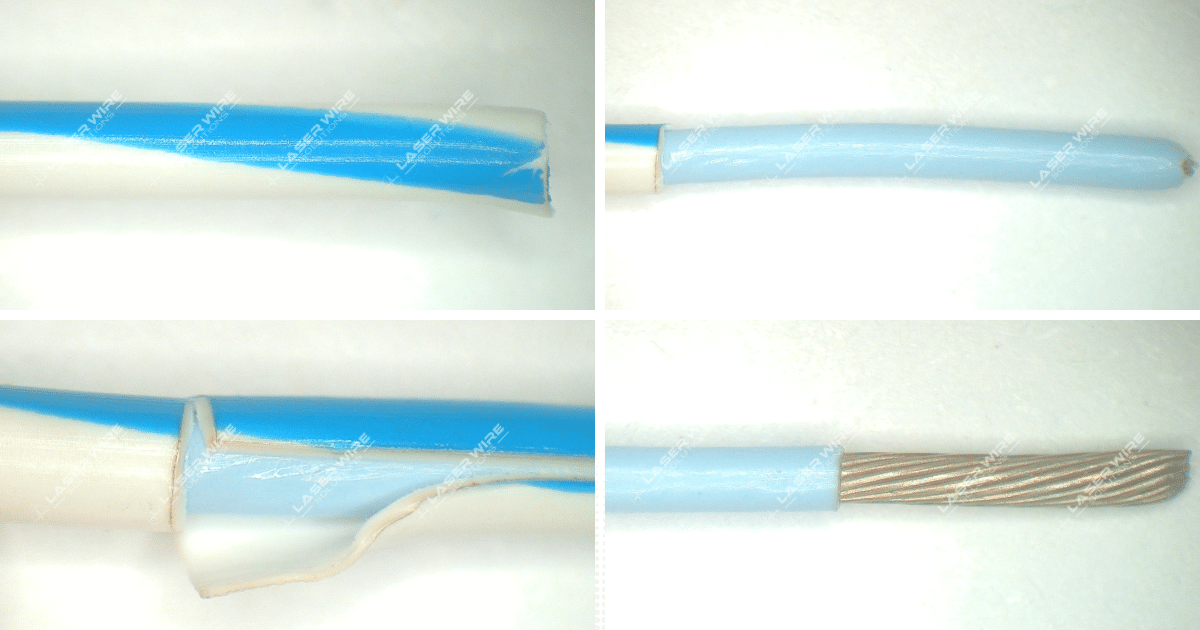

- High Quality – lasers offer precision stripping with nick-free results (as the laser beam deflects off the inner conductor with little or no residue).

- Consistent Results – with +/- 0.004” (0.102 mm) repeatability, unlike traditional tools which wear over time and can therefore vary cutting parameters.

- Increased Productivity– multiple wires can be processed at once.

- Versatility – different laser sources and configurations can strip a wide variety of wire and cable types, both semi-automatically and fully automatically, and with a range of strip patterns, including windows on jackets.

- Fast Processing Speed – up to 80” (2000 mm) per second stripping speed for fastest processing.

- Works with Complex Wire Structures – can strip with ease bonded insulations as well as out of round cables, such as metallic or shielded multi-conductor jackets.

- Automated – inline options are available for a number of our machines.

- Reduced Scrappage – very low process rejects because of the high-quality yield.

- Zero Risk – no risk of process failure in manufacture and also in end-product use (e.g. medical device manufacture).

- Low Depreciation – laser is a contact-less process and therefore it is not subject to wear and tear (no need to replace blades as with mechanical or manual processes).

- Safe Method – a Class 1 laser safety enclosure for our Class 4 laser systems means that our machines can be used on an open shop floor. All equipment is fitted with dual fail-safe interlocked optical enclosure and monitoring. The main health and safety requirement is to have a fume extractor installed. All our equipment meets and exceeds UL, OSHA and EU legislation.

- Low Maintenance – very few consumables required, other than periodic extraction filter changes and cleaning of lens with disposable lens wipes.

- Energy Efficient – many of our systems run on low power using single phase supply.

Laser Wire Stripping Applications

Lasers are ideal for a number of different applications across a variety of industries. In short, any original equipment manufacturer that is required to make connections between delicate fine wires and cables would benefit from implementing laser wire stripping into their production line.

Our machines are capable of stripping virtually any type of wire insulation or shielding to meet your requirements. The most common applications we encounter include:

- Catheter wiring

- Motor windings

- Electric vehicle cables

- Infiniband cables

- Thermocouples

- Microwave cables

Laser Wire Solutions are a leading manufacturer of laser wire stripping machinery to medical, automotive, aerospace, defense, and data fields around the globe. We have delivered numerous units to blue chip companies within the EMEA, APAC, and LATAM regions, becoming an integral part to these companies production lines.

Our laser experts are on hand to support you throughout your project. Find your nearest distributor or contact Laser Wire Solutions directly here.