Lasers can be an appropriate alternative to chemical and manual wire stripping particularly for high value, very fine wires that are used in medical devices such as catheters because it allows for a quick and precise cut with little to no residue.

There are a number of wires ideal for laser wire stripping. This includes the following applications (typically where mechanical tools are no longer able to cope and when chemical methods are ruled out on safety grounds).

The below is a summary of when laser wire stripping should be used to achieve optimal results:

Small Wires

- Very thin wires – e.g. <38 AWG

- Microcoax – especially <40 AWG, and/or especially micro-coax ribbons

High Value Cables

These wires are typically found in medical, defense and aerospace markets

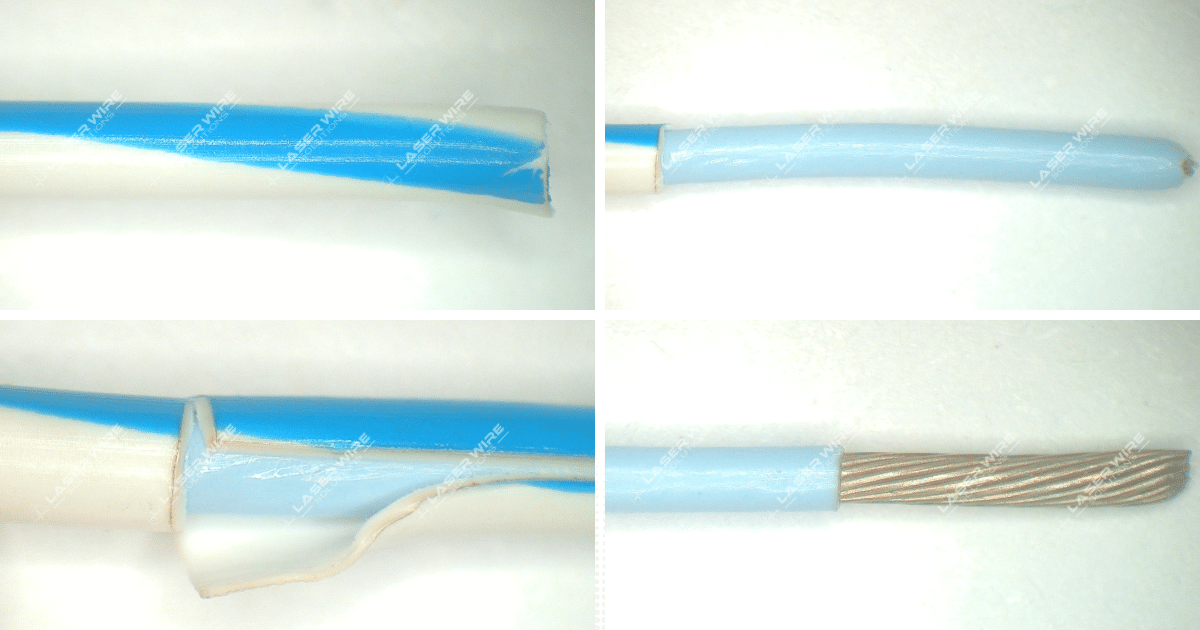

- Very thin insulation (blades cause too much damage); e.g. ultrasound cables, RF ablation catheters or pacemaker electrodes

- Round metallic jackets, e.g. high-powered RF cables and high temperature mineral-insulated thermocouples

- Microwave coax cables

Complex Cables

- Foil insulations, e.g. on twin-ax data cables

- Ribbon cables

- Wires with bonded insulation

- Tough insulations, e.g. fibre glass

- Out of round cables

Magnet or Enamelled Wires

- Thin magnet wire <38 AWG

- Ribbonized magnet wire (bifilar, tri-filar, etc)

- Very small magnet wire coils that need high quality

Complex Strip Patterns

- Windows and complex strip patterns that mechanical solutions struggle with, but lasers easily master

High Quality

- When strip quality is paramount, i.e. when nicks, damage and residue cannot be tolerated

Lasers are ideal for a number of different applications across a variety of industries. In short, any original equipment manufacturer that is required to make connections between delicate fine wires and cables would benefit from implementing laser wire stripping into their production line.

Review our application pages, to find out more about the types of wires which are suited for laser.

There are many suitable wires for laser stripping, so if your wire has not been described here our team can discuss your requirements to find a suitable solution for your wire stripping needs. Laser wire stripping is the best solution when handling many different types of wires and cables. It provides results unachievable by conventional wire stripping methods such as thermal wire stripping, chemical wire stripping, and mechanical wire stripping.