In aerospace engineering, wiring harnesses form the nervous system of modern aircraft. They power avionics, flight controls, communication systems, and safety equipment. Yet, behind their critical role lies a challenge often overlooked: the hidden cost draining aerospace harness production.

While manufacturers account for copper, insulation, and connectors, what truly strains budgets are inefficiencies, rework, and compliance failures. Traditional manual wire stripping and outdated methods not only inflate labor costs but also create scrap and rework that delay entire projects.

The solution? Laser wire stripping. A non-contact, precision technology increasingly adopted by aerospace leaders. It is transforming how harnesses are built, dramatically reducing hidden costs while improving compliance and reliability.

The Role of Wire Harnesses in Aerospace Systems

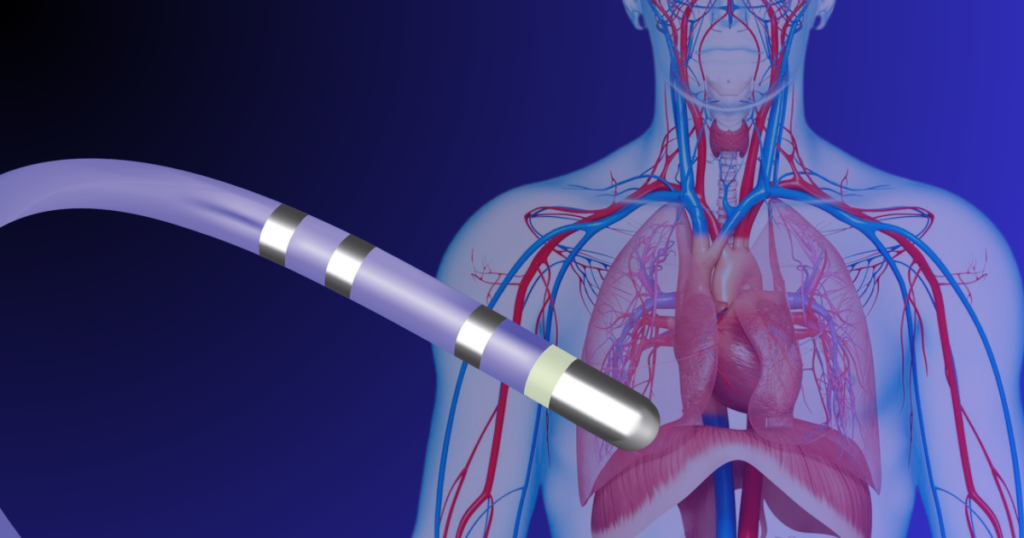

Wire harnesses are the backbone of aerospace systems, ensuring safe and reliable electrical connections. An aircraft can contain hundreds of miles of wiring, each strand requiring accurate stripping before termination. A single nicked wire can compromise performance or lead to costly failures.

Why Aerospace Harness Manufacturing Is So Complex

Unlike automotive harnesses, aerospace wiring is custom-built for each aircraft type, often with unique requirements for insulation (Kapton®, PTFE, or enamel). Every harness must comply with strict standards such as NASA-STD-8739.4 and FAA/EASA regulations, making the process labor-intensive and highly regulated.

Understanding the Costs in Harness Production

Material Costs vs. Labor Costs

-

Material costs (copper, connectors, insulation) are relatively stable.

-

Labor costs dominate – technicians manually strip, route, and assemble thousands of wires.

But it’s the hidden costs that create financial strain.

The Hidden Costs Manufacturers Often Overlook

-

Scrap and waste from damaged wires

-

Rework when harnesses fail inspection

-

Delays caused by compliance re-certifications

-

Supply chain slowdowns when specialty wires are scrapped

The Hidden Cost Draining Aerospace Harness Production

Scrap and Rework from Manual Processes

Traditional mechanical wire stripping often damages conductors. Damaged wires cannot be repaired; they must be scrapped, forcing rework and wasting costly aerospace-grade materials.

Labor-Intensive Wire Stripping

Manual stripping requires highly trained technicians, but even skilled workers introduce inconsistencies. With thousands of wires per aircraft, small inefficiencies multiply into major delays.

Compliance and Certification Failures

Every harness must pass rigorous testing. Failed inspections lead to additional labor, documentation, and certification cycles. All adding hidden costs.

Supply Chain Delays Amplifying Costs

When scrap rates are high, manufacturers must reorder specialty wires, delaying assembly and increasing overall costs.

Introducing Laser Wire Stripping

What Is Laser Wire Stripping?

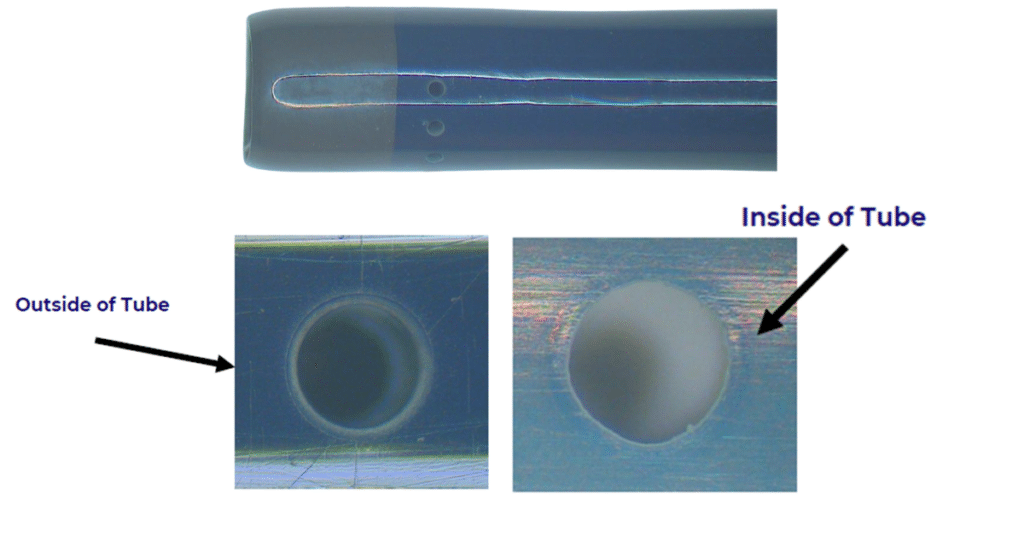

Laser wire stripping uses focused laser energy to remove insulation with micron-level precision. Unlike blades or chemicals, lasers don’t touch the conductor, ensuring repeatable, damage-free results.

How It Differs from Mechanical and Chemical Methods

-

Mechanical stripping: risks conductor damage, requires labor.

-

Chemical stripping: messy, hazardous, and unsuitable for aerospace.

-

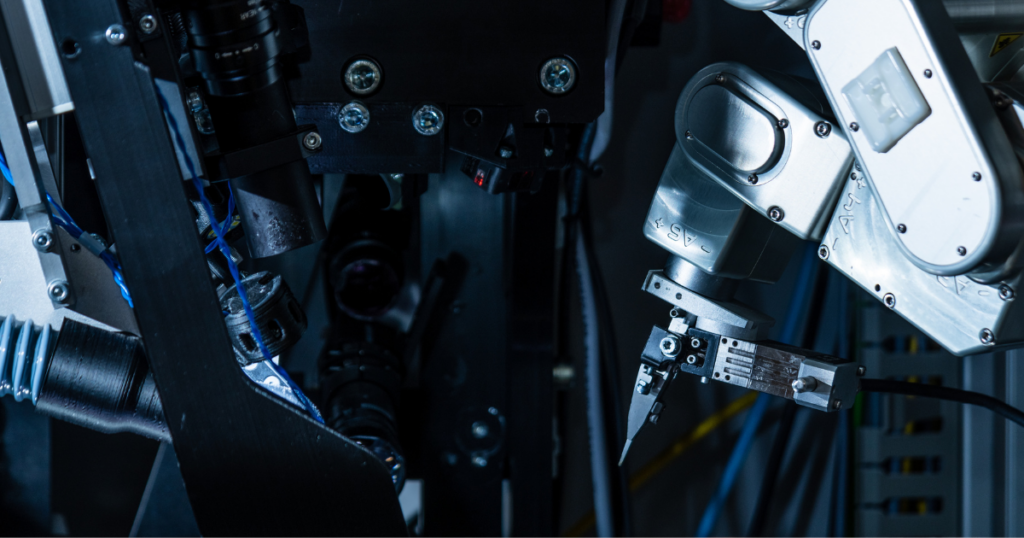

Laser stripping: precise, consistent, non-contact, and automatable.

How Laser Wire Stripping Reduces Hidden Costs

1. Reducing Scrap and Rework Rates

Laser stripping eliminates conductor damage, drastically cutting scrap. By reducing rework cycles, aerospace firms save time, labor, and materials.

2. Cutting Labor Dependency

Automation allows one operator to oversee multiple laser systems. This lowers reliance on skilled manual labor while accelerating throughput.

3. Improving Compliance and Certification Success

Laser wire stripping produces repeatable, inspection-ready results that meet FAA, EASA, and NASA standards. Fewer failures mean faster certifications.

4. Enabling Complex Aerospace Harness Designs

As avionics evolve, manufacturers require ultra-fine gauge wires (as small as 50 microns). Manual stripping struggles here, but lasers excel, supporting the miniaturization and lightweighting of next-generation aircraft.

FAQs on Harness Costs and Laser Wire Stripping

Q1: What makes aerospace harness production so costly?

The costs stem not from materials, but from labor, scrap, rework, and compliance failures.

Q2: How does laser wire stripping reduce costs?

It cuts rework, reduces labor dependency, ensures compliance, and eliminates scrap.

Q3: Can laser stripping handle aerospace-grade insulations?

Yes, including Kapton®, PTFE, and enamel-coated wires.

Q4: Is laser stripping safe for ultra-fine wires?

Absolutely. Lasers can strip wires down to 50 microns without conductor damage.

Q5: How fast is the ROI on laser stripping equipment?

Most suppliers recover costs within 2–3 years due to labor and scrap reduction.

Q6: Are aerospace companies already using this technology?

Yes. A number of large OEMs and numerous Tier 1 suppliers are actively adopting laser wire stripping.

Why Laser Wire Stripping Is the Future of Aerospace Harness Production

The hidden cost draining aerospace harness production lies in manual inefficiencies, scrap, rework, and certification hurdles. Traditional methods are no longer sustainable in a competitive global aerospace market.

Laser wire stripping eliminates these inefficiencies by delivering precision, repeatability, and compliance-ready results. It reduces hidden costs, accelerates production, and prepares manufacturers for the future of aerospace wiring.

For aerospace companies, adopting laser-based automation isn’t just a cost-saving measure, It’s a competitive necessity.