Scale wire production with Reel-to-Reel laser processing that delivers QC-inspected wire directly to your assembly line.

Get spools of pre-stripped, QC-verified wire exactly when you need them.

Ideal for high-volume applications like RF / PFA catheters, neurostimulators, and cardiac leads.

Free up time and resources by outsourcing wire prep, eliminate the requirement for skilled operators.

Micron-level accuracy with zero damage to delicate wire insulation.

Fits into existing manufacturing workflows without disruption.

Let us know your wire type, gauge, strip zones, and insulation specs.

Laser precision wire stripping with zero damage to the conductor.

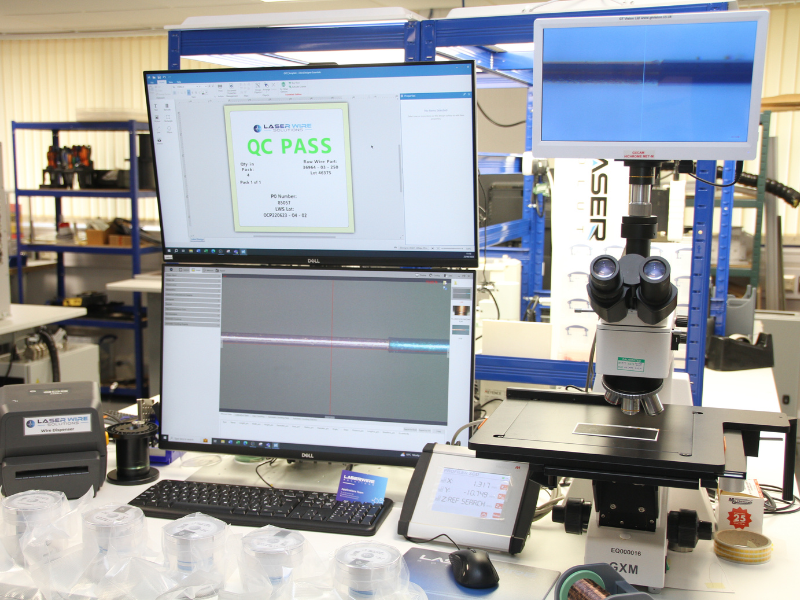

Each spool is inspected for accuracy and consistency before delivery.

Receive ready-to-use, QC-approved wire exactly when you need it.

Laser processed spool-to-spool (reel-to-reel) wire processing may be the fastest way to scale without bottlenecks.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.