How Lasers Enable Precision Catheter Manufacturing: From Wire Processing to Finished Devices

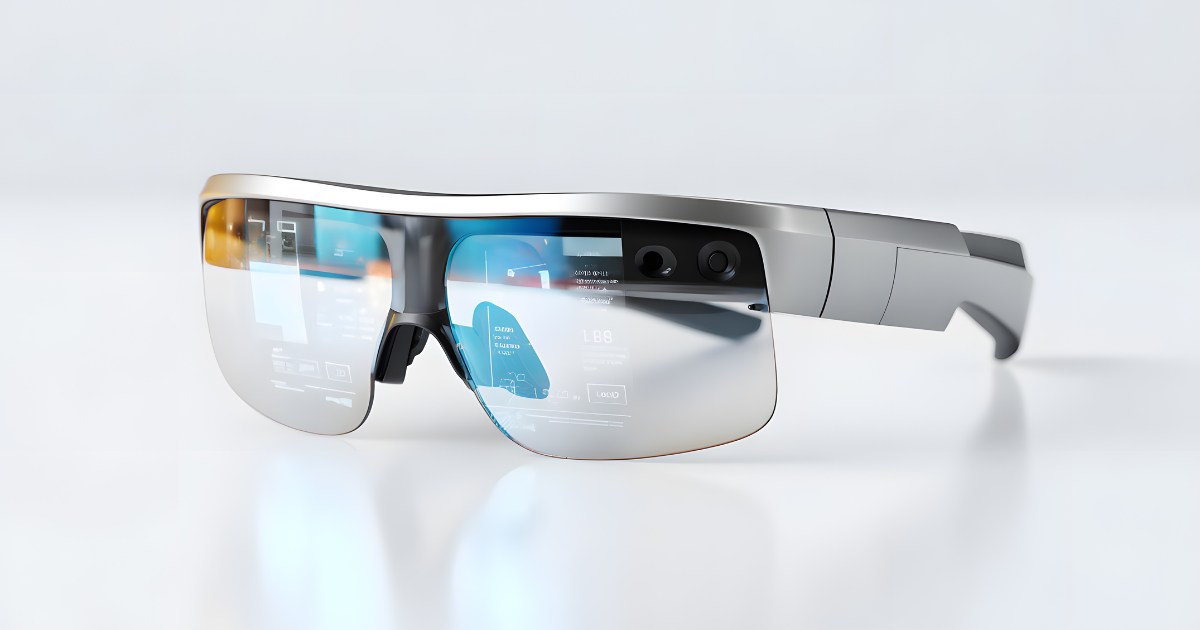

How do you manufacture a catheter that is small enough to navigate the human vascular system, flexible enough to bend without failure, and precise enough

Learn with Laser Wire Solutions. From innovative thinking to application expertise, our solutions experts solve your toughest challenges and provide solutions to meet your project needs.

Our technical articles will covers a variety of topics relating to our area of expertise to help solve your challenges.

How do you manufacture a catheter that is small enough to navigate the human vascular system, flexible enough to bend without failure, and precise enough

As medical devices continue to shrink, integrate more electronics, and face tighter regulatory oversight, one truth is becoming increasingly clear: wire stripping for medical devices

Many manufacturing production lines face increasing pressure to deliver precision, consistency, and speed; yet many operations remain bogged down by outdated, overly complex systems. The

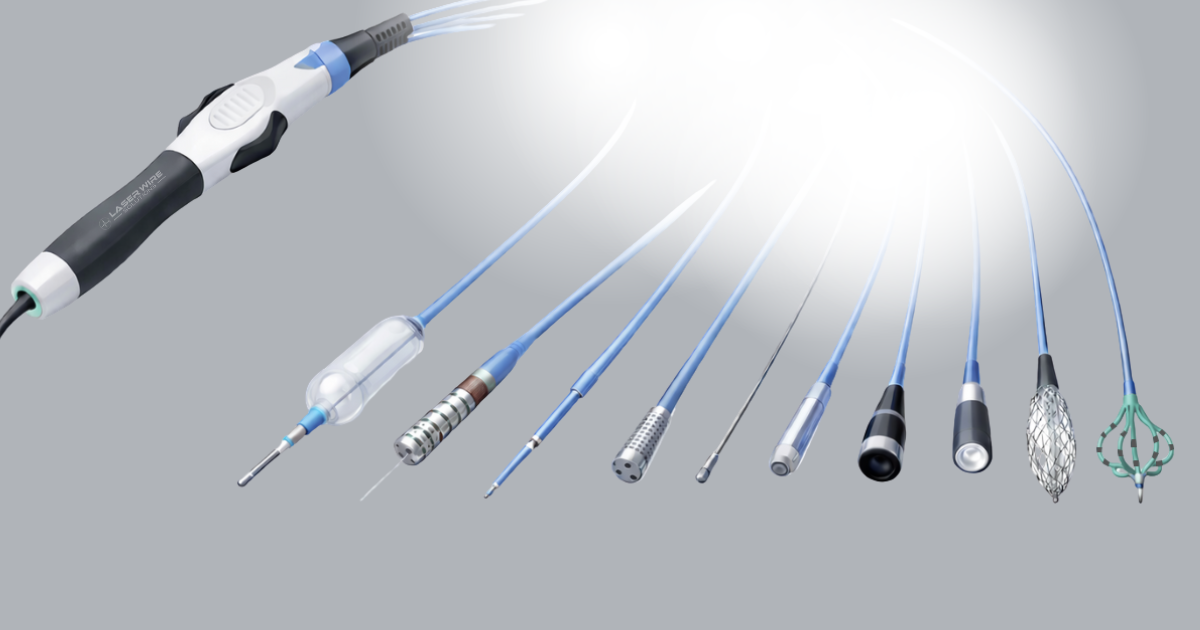

Wearable technology is rapidly expanding across industries that include consumer electronics, healthcare, sports performance, vision technology, and advanced textiles. Behind every small wearable device is

Production issues rarely start where you expect. In many manufacturing environments, especially high-volume builds and medical OEM lines, the root cause of scrap, rework, or

The Challenge of Setup Time in Wire Stripping Setup time has long been one of the most significant barriers to efficiency in wire processing. Whether

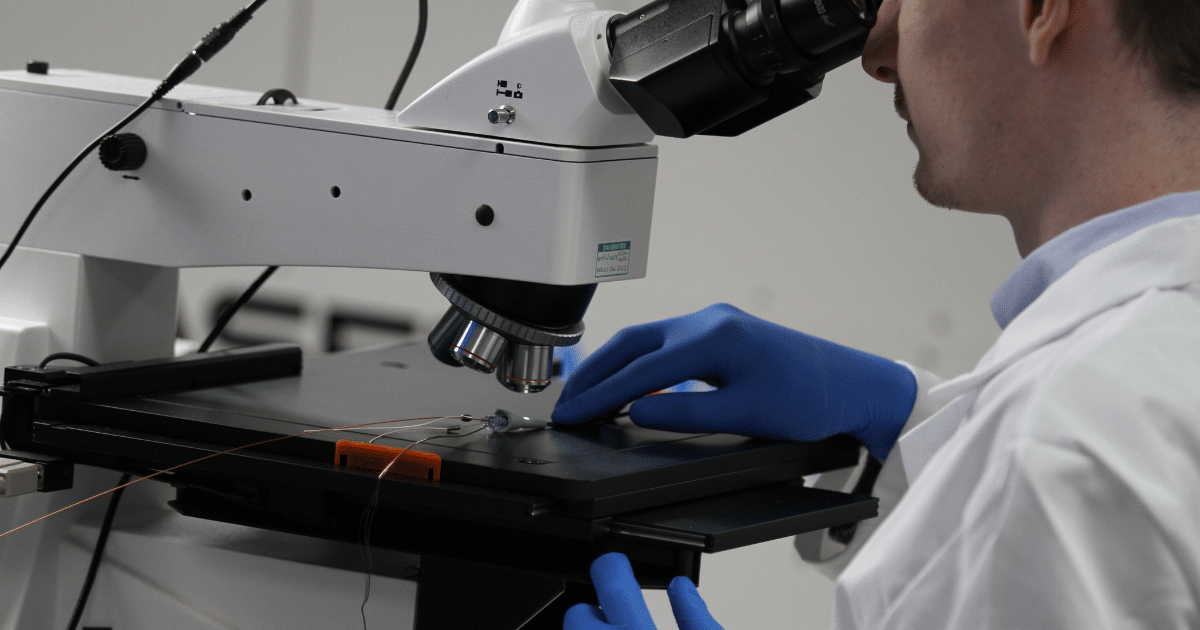

Every medical device manufacturer faces the same challenge: how to validate critical processes quickly, confidently, and at scale. Wire stripping – though a small step

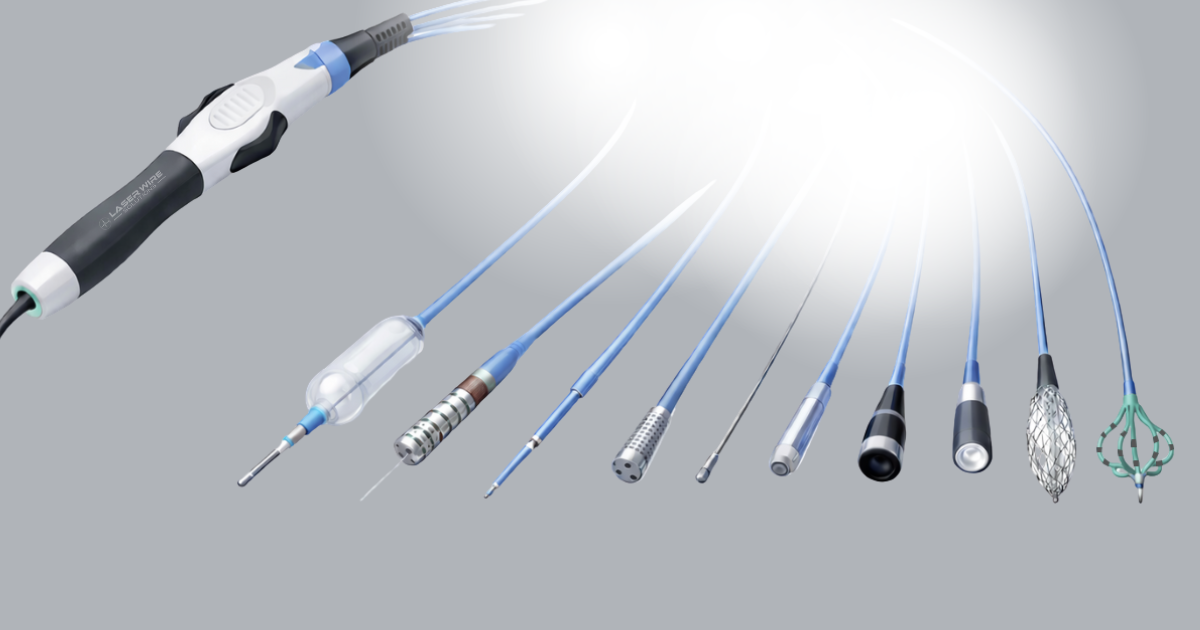

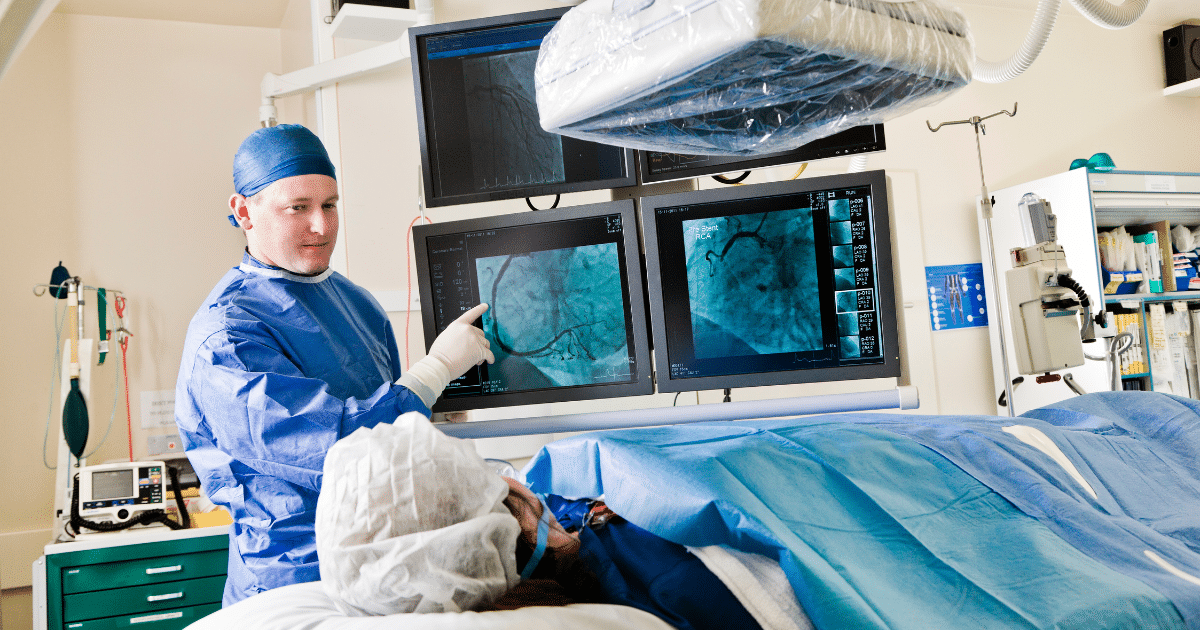

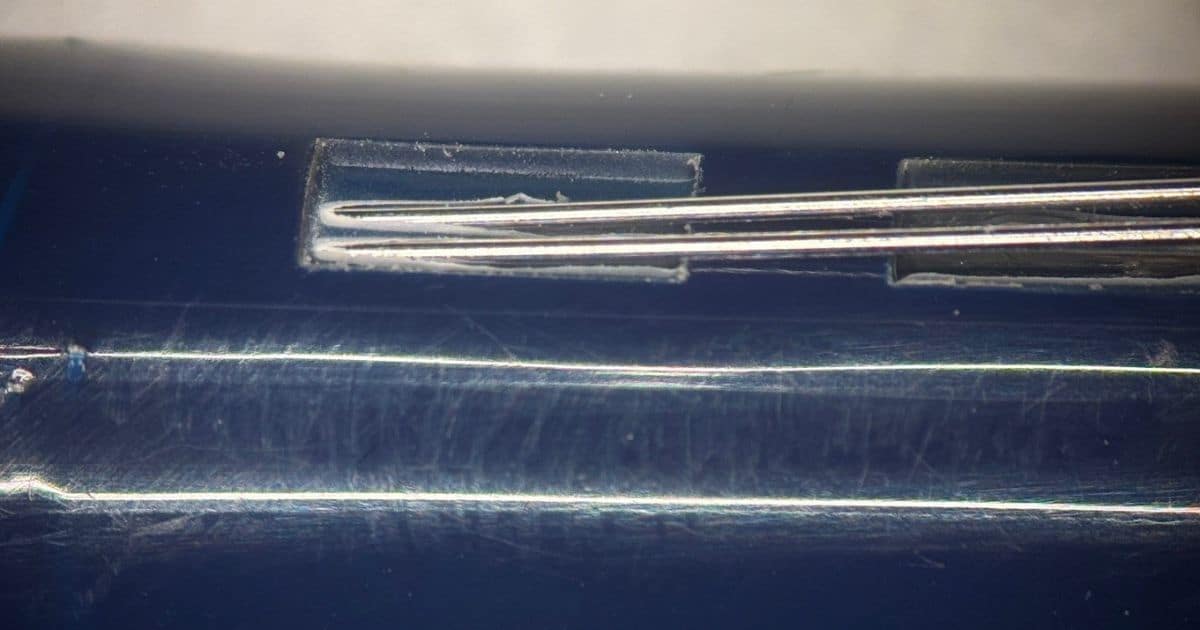

In electrophysiology / EP catheter manufacturing, precision is everything. Each catheter can contain dozens of hair-thin wires, connecting electrodes, sensors, and thermocouples that must perform

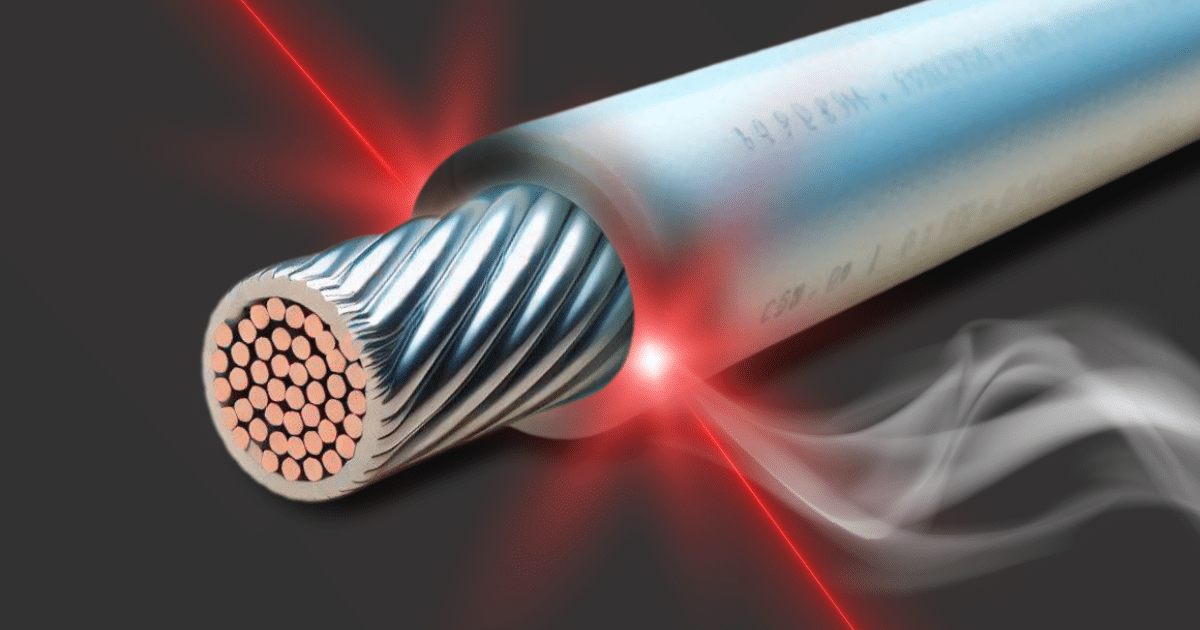

Traditional stripping tools, whether it’s mechanical blades or thermal tweezers, often risk nicking, contaminating, or deforming conductors during insulation removal. That’s where laser wire cutting

Laser wire processing has revolutionized industries that rely on high-precision wire stripping and preparation. From aerospace to medical device manufacturing, companies need accurate, repeatable, and

Why Data Center Cable Prep is Crucial for Cable Manufacturers in 2026 For data center cable manufacturers, 2026 marks a turning point. With demand for

Medical catheters are life-saving devices used in procedures ranging from cardiovascular interventions to neurological treatments. The integrity of these devices depends heavily on the precision

In aerospace engineering, wiring harnesses form the nervous system of modern aircraft. They power avionics, flight controls, communication systems, and safety equipment. Yet, behind their

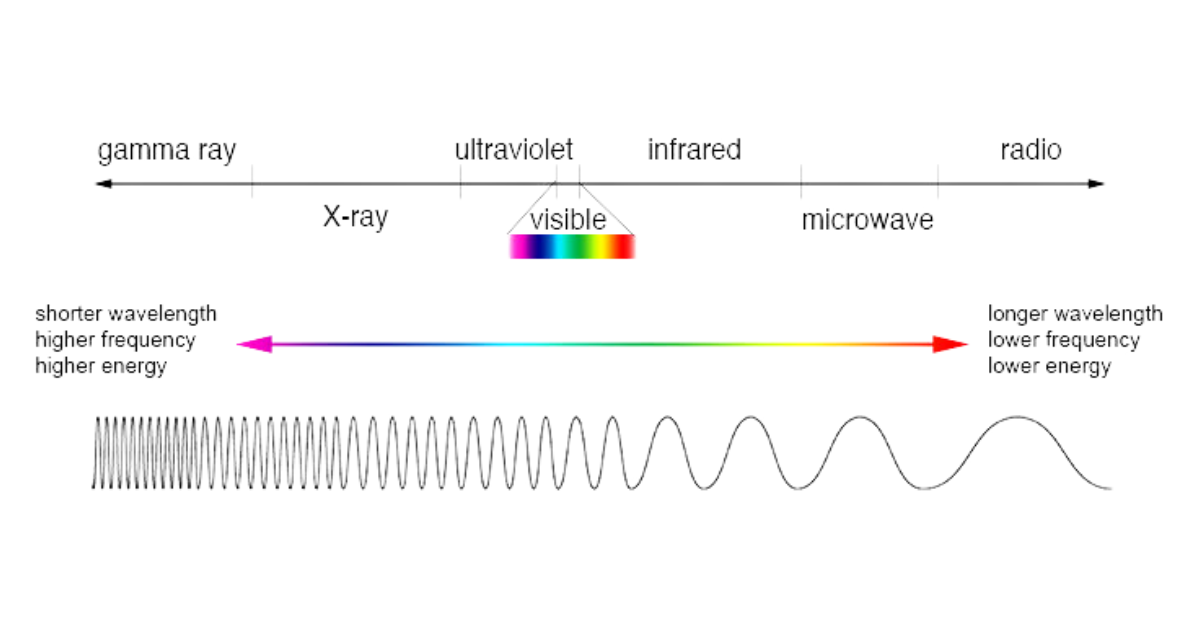

Introduction to Wire Stripping Wire stripping is the process of removing the insulation layer from electrical wires to expose the conductive metal beneath. It’s a

The Vital Role of Cable Preparation in Aerospace In the aerospace industry, every wire, every connection, and every cable plays a vital role in ensuring

Introduction to Automotive Wire Stripping Challenges Electric vehicles (EVs) are transforming the automotive industry, but they also introduce a new level of complexity, especially in

Introduction to Spool-to-Spool Laser Stripping As medical technology continues to advance at an incredible pace, the demand for precision and efficiency has never been higher.

By now, most manufacturers working in sectors like medical devices, aerospace, automotive, and electronics are well aware of the upcoming US ban on methylene chloride

Is your wire stripping process holding back your validation efforts? In medical device assembly, tweezers are still widely used to strip insulation from fine wires,

If you’ve ever browsed one of our datasheets or looked into machine capabilities, you may have come across the term “breakout length.” It might sound

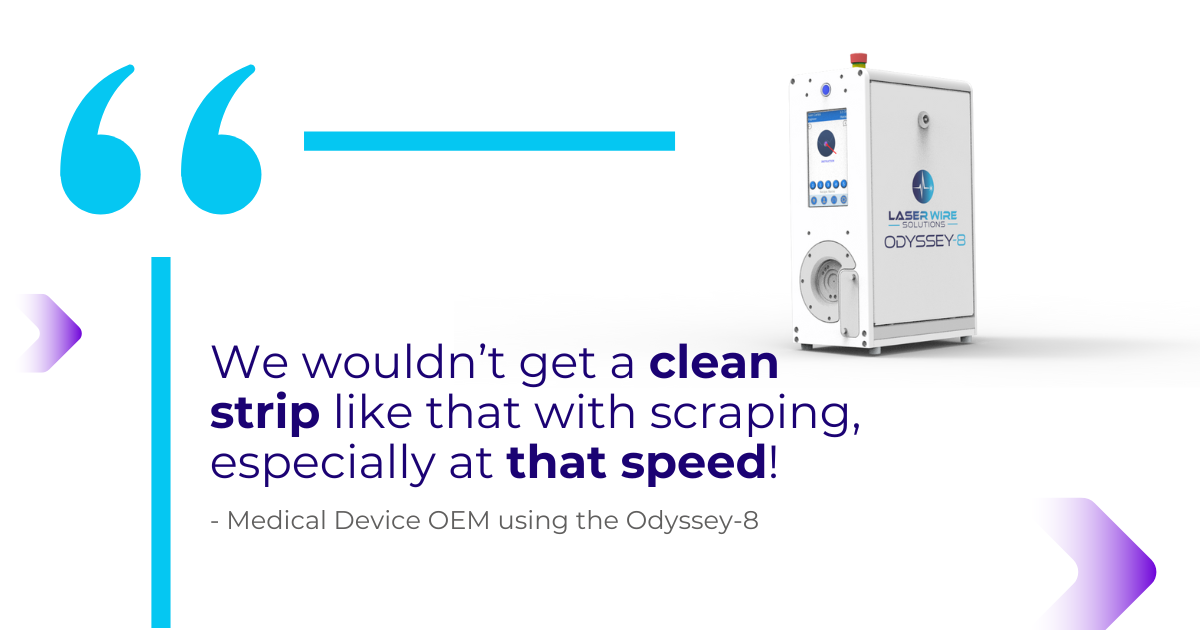

At Laser Wire Solutions, customer feedback doesn’t go into a suggestion box—it fuels innovation. And the latest improvements to our Odyssey-8 laser stripping platform are

As demand increases for higher throughput and tighter process control in wire processing, manufacturers are moving away from standalone operations toward fully integrated, inline solutions.

A global leader in RF ablation and cardiac mapping catheters for treating cardiac arrhythmia transitioned from abrasive cone wire strippers to laser-based stripping. This move

If you’re still relying on cone stripping to prepare wires for soldering, you could be introducing hidden flaws into your products—long before a soldering iron

In precision manufacturing environments, wire processing constitutes a critical process parameter with direct influence on product reliability metrics and overall system performance. The quantitative analysis

Precision is the backbone of modern manufacturing, especially when working with delicate materials and intricate designs. However, traditional wire processing methods often introduce unwanted heat,

For engineers designing critical medical devices, the challenge of ensuring biocompatibility in wiring is paramount. While material selection is crucial, the impact of wire processing,

Nitinol stands at the forefront of material science innovation, transforming the landscape of medical device manufacturing and engineering. This sophisticated nickel-titanium alloy has become essential

The Critical Role of Precision in Medical Wire Processing Medical device manufacturing demands an unprecedented level of precision, particularly in wire insulation removal. Laser wire

In the intricate world of electronics, particularly in critical industries like medical devices even the slightest electrical noise can have significant consequences. A key factor

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, aerospace, defense and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2026 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.