The Critical Role of Precision in Medical Wire Processing

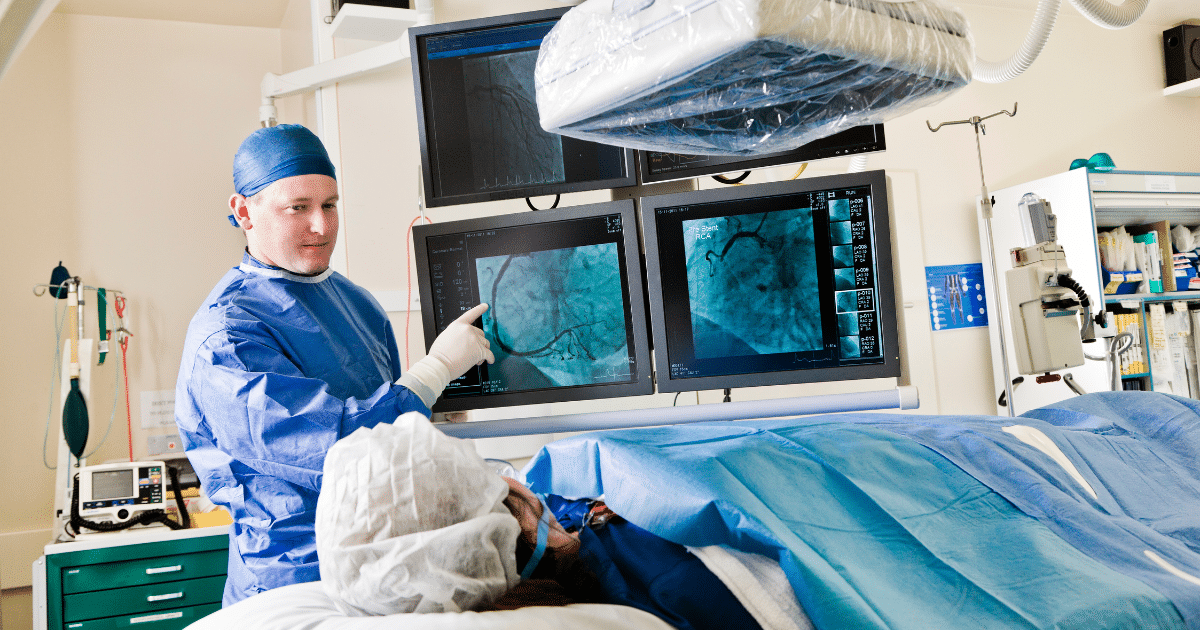

Medical device manufacturing demands an unprecedented level of precision, particularly in wire insulation removal. Laser wire stripping has emerged as a transformative technology, offering unparalleled control and reliability for the most demanding medical applications.

Medical Wire Insulation Materials: A Technical Overview

Enamel Insulation: The Cornerstone of Precision Medical Wiring

Enamel coatings represent a critical challenge in medical wire processing, characterized by:

- Extremely thin layer thickness (0.5-2 μm)

- High dielectric strength

- Complex molecular composition

Enamel Composition Variations

- Polyurethane-based enamels

- Polyamide-based formulations

- Polyesterimide coatings

Advanced Insulation Materials in Medical Devices

- Polyimide Insulation

- Exceptional thermal stability

- Biocompatibility

- Minimal outgassing characteristics

- PTFE (Teflon) Micro-Coatings

- Ultra-low friction properties

- Chemical inertness

- Minimal surface interaction

- Specialized Polymer Jackets

- Silicone-based coatings

- Fluoropolymer advanced formulations

- Biocompatible polymer systems

Laser Processing: Precision Engineering Considerations

Wavelength Optimization for Medical Wire Stripping

Optimal Wavelength Ranges

- 355nm: Precision enamel removal

- 1064nm: Advanced polymer processing

- 266nm: Ultra-precise micro-coatings

Critical Processing Parameters

Enamel Removal Specifications

- Pulse Duration: 10-30 nanoseconds

- Energy Density: 1.2-2.5 J/cm²

- Precision Accuracy: ±5 μm strip length

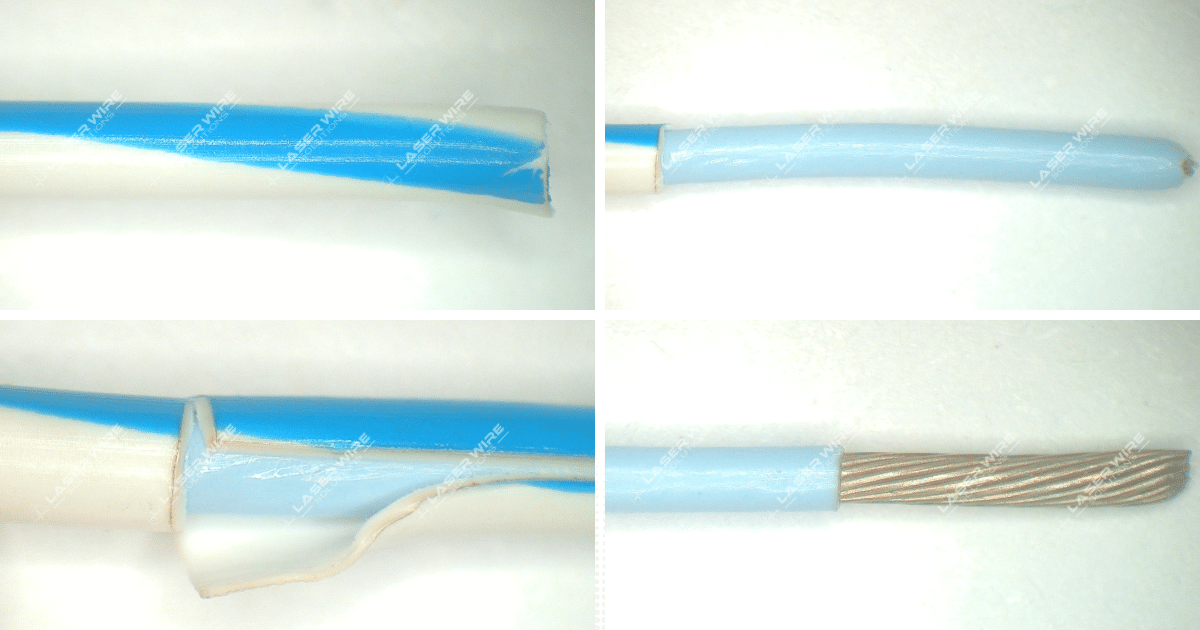

Performance Metrics for Medical Applications

Key Performance Indicators:

- Strip Uniformity: >99.7%

- Substrate Damage: <0.05% surface alteration

- Electrical Integrity Preservation

- Minimal Thermal Impact

Technological Challenges and Innovative Solutions

Advanced Processing Techniques

- Real-time optical monitoring

- Adaptive energy modulation

- Machine learning-enhanced parameter optimization

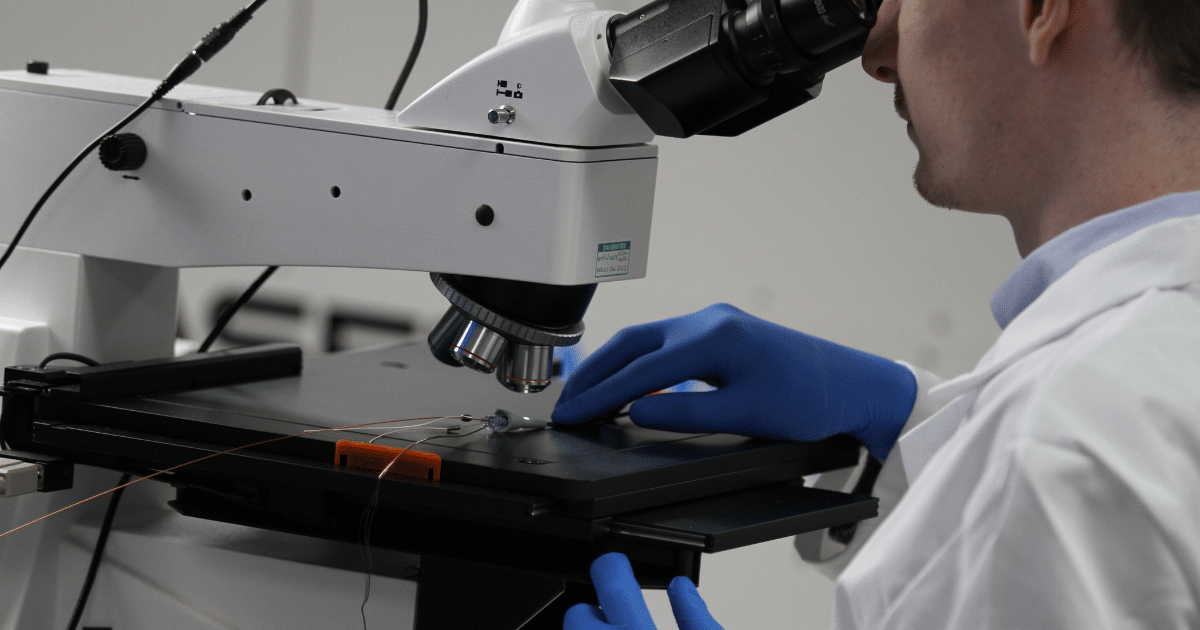

Quality Control Methodologies

- Microscopic surface examination

- Electrical resistance validation

- Statistical process control

Practical Implementation Considerations

Wire Diameter Ranges

- Micro-diameter processing: 30-50 AWG

- Typical medical device applications: 36-44 AWG

System Integration Requirements

- Cleanroom compatibility

- Precise environmental controls

- Network-enabled monitoring systems

Compliance and Regulatory Considerations

Critical Certification Standards

- ISO 13485 Medical Devices

- FDA Quality System Regulations

- IEC 60601 Medical Electrical Equipment

Emerging Technologies on the Horizon

Future Processing Innovations

- Adaptive laser processing systems

- AI-enhanced parameter optimization

- Real-time quality prediction algorithms

Conclusion: Precision at the Molecular Level

Laser wire stripping for medical devices represents the pinnacle of manufacturing precision. By understanding and manipulating complex material interactions, manufacturers can achieve extraordinary reliability and performance.

Technical Consultation

For specialized medical wire processing solutions:

- Email: sales@laserwiresolutions.com

- Phone: +44 (0) 144 384 1738

- Or, request a demo.