The healthcare industry, while vital, often faces challenges related to environmental sustainability. One such area is the manufacturing of medical devices, particularly catheters. Traditional manufacturing methods can lead to significant waste and environmental impact, with many wires with a poor strip quality or with residue remaining on the wire being scrapped. This blog post will explore how laser wire stripping technology can revolutionize catheter manufacturing, promoting sustainability and efficiency.

The Problem with Traditional Methods

Traditional methods for stripping wires in catheter manufacturing often involve mechanical stripping or chemical processes. These methods can result in:

- Waste: Excessive wire material is often discarded, leading to material waste.

- Environmental Impact: Chemical processes can generate hazardous waste and contribute to pollution.

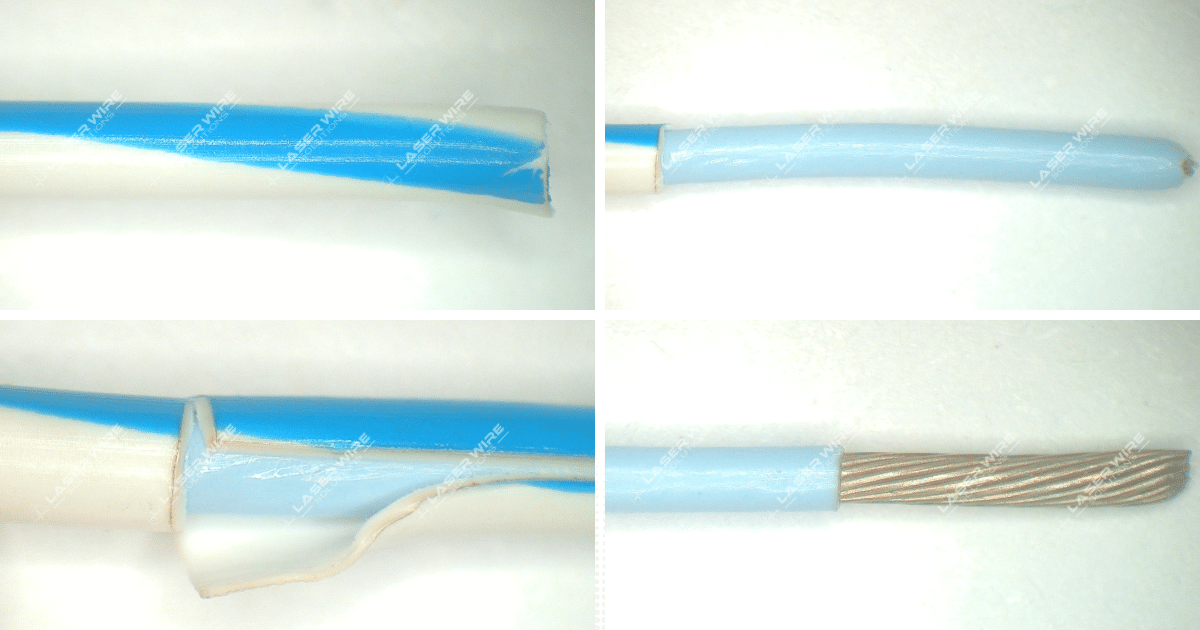

- Quality Issues: Mechanical stripping can cause damage to the wire, compromising the quality of the catheter.

Laser Wire Stripping: A Sustainable Solution

Laser wire stripping technology offers a cleaner, more efficient alternative to traditional methods. Here’s how it works:

- Precision: Lasers can strip wires with extreme precision, minimizing waste.

- Efficiency: The process is highly automated, reducing labor costs and increasing production speed. With both the wire stripping process and the quality checking process.

- Sustainability: Laser stripping eliminates the need for harmful chemicals, reducing environmental impact.

- Quality: The non-contact nature of laser stripping prevents damage to the wire, ensuring high-quality catheters.

Investing in Laser Wire Stripping Technology

By adopting laser wire stripping technology, manufacturers can:

- Reduce waste: Minimize the amount of wire material discarded, saving costs and resources.

- Improve efficiency: Streamline production processes, increasing output and reducing lead times.

- Enhance sustainability: Contribute to a greener manufacturing environment by eliminating hazardous chemicals.

- Ensure quality: Produce catheters with consistent quality and reliability.

Suitable Wires for Laser Wire Stripping

- Stainless steel: Known for its strength and corrosion resistance, stainless steel is a popular choice for catheter components.

- Coated wires: Wires with coatings like Teflon or polyurethane can be successfully stripped using laser technology without damaging the inner conductors.

- Fine-gauge wires: Laser stripping is ideal for precisely removing insulation from delicate, fine-gauge wires used in catheters, such as those in the AWG 32-40 range.

- Complex wire configurations: Lasers can handle intricate wire geometries and bundles, making them suitable for complex catheter designs.

Laser Wire Solutions: Your Partner in Sustainability

Laser Wire Solutions is a leading provider of laser wire stripping technology. Our innovative solutions can help catheter manufacturers achieve their sustainability goals while improving product quality and efficiency.

The transition to sustainable manufacturing practices is essential for the healthcare industry. Laser wire stripping offers a promising solution for catheter manufacturers seeking to reduce waste, minimize environmental impact, and enhance product quality. By investing in this technology, manufacturers can not only contribute to a more sustainable future but also gain a competitive advantage in the market.

Experience the benefits of laser wire stripping. Schedule a demo with our experts and see how we can improve your efficiency and sustainability.