How do you ensure your company is continually innovating to stay ahead of the curve in a fast moving industry? The medical industry is one which is constantly evolving to meet the needs of patients before those needs have yet been realized.

From making a better experience for the patients, to improving the availability of their devices around the world, Siemens Healthineers have found the secret ingredient to demonstrate their position as pioneers in this industry, and it’s only made possible through their culture.

We caught up with Robert Balfour, Senior Process Engineer at Siemens Healthineers to find out how they made this possible.

Why do you think innovation is becoming increasingly more important in the medical device sector?

Our company’s new ambition is pioneering breakthroughs in healthcare for everyone, everywhere. So the drive is to put MRI in places which it has never previously been in the world. With a lot of the legacy products, it’s not possible to put them in remote locations so a lot of the innovation in our products is to drive the ability to have MRIs in places where it’s not been possible to do it before.

What makes innovation possible at Siemens Healthineers?

We have an onsite R&D team, onsite manufacturing, and onsite process engineering and development, so it’s super important for us to be able to take something from prototype to mass production using that integration across all parts of the business.

What’s the biggest / most important lesson you’ve learnt about innovating at Siemens Healthineers?

We’ve got a lot of innovation going on currently with the new products that we’re manufacturing, and a huge part of that is making sure that we can do proper design for manufacture; getting the people who are going to be building the products involved right at the beginning to ensure that the product not only works, but is cheaper, quicker, and easier to manufacture as well.

How do you foster a culture of innovation at Siemens Healthineers?

We acknowledge that we have a huge number of experts within the business who are going to have great ideas and the culture is that if you’ve got an idea you can bring it to the table. We will look at it, people will work on it.

There’s a huge amount of expertise but people constantly happy to learn. Innovation is celebrated and people just want to ask questions and grow.

Laser Wire Solutions currently works in partnership with Siemens Healthineers on creating a machine suitable for their wire processing needs to make the MRI scanners that will be built for use around the world. We wanted to find out more about their processes and why they chose to work with Laser Wire Solutions.

How does the Laser Wire Solutions process aid in the speed of building your MRI machines?

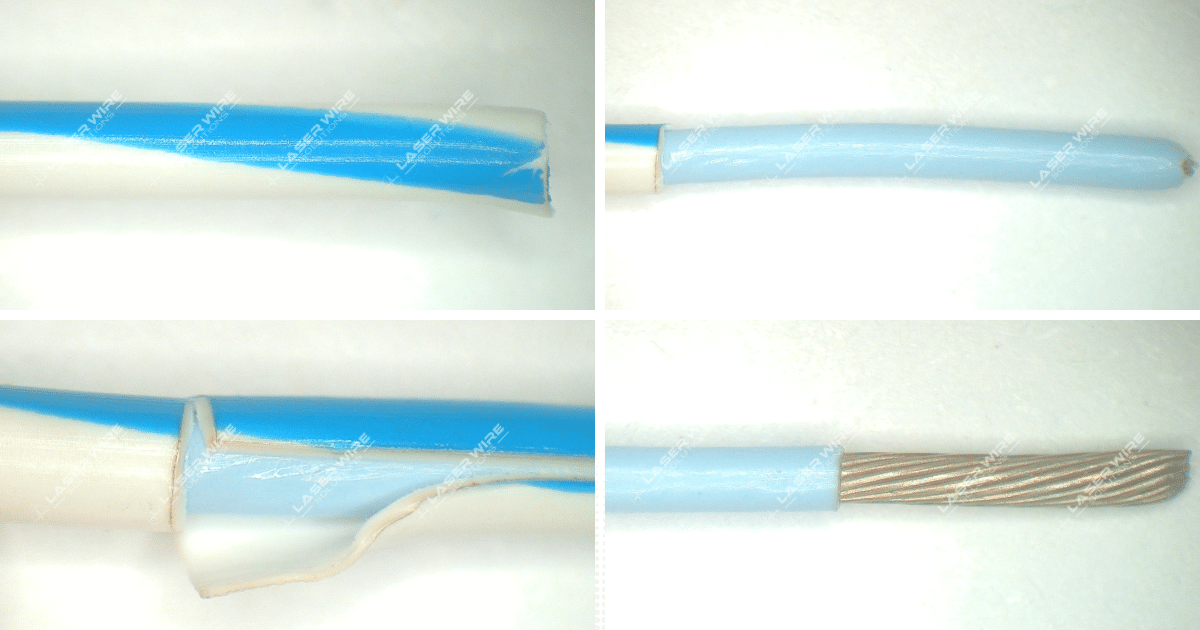

The previous process used to remove the enamel from our wires was very time-consuming and carried inherent EHS and quality risks. The Laser Wire Solutions machine has allowed automation of the enamel removal process, resulting in speeding it up significantly, eliminating the EHS concerns and significantly improving product quality.

Why did you choose to work with Laser Wire Solutions?

When we first visited the Laser Wire Solutions site in South Wales, we were really impressed by the expertise, the skills the business showed, how quickly they managed to process the wire, and the clear knowledge of the stripping. It’s important to us to work with a fellow UK business and keep things local. It was very clear there was a lot of expertise in stripping wire.

Make sure you follow Siemens Healthineers on LinkedIn and Twitter to keep up to date with their mission to get more MRI machines in remote locations around the world.

If you’re interested in working with Laser Wire Solutions, get in touch with our team of experts today.