Laser Wire Solutions is gearing up for a busy show at the 18th annual Electrical Wire Processing Technology Expo which will take place at the Wisconsin Center, Milwaukee on May 9th and 10th. The company this year will be co-exhibiting with the Schleuniger group, in booth 1732.

Laser Wire Solutions’ CEO, Paul Taylor states that “We have had an exceptionally successful and busy period since the last show in 2017 and this has meant that we have a number of new, innovative products to showcase at this year’s event”, additionally, “We have worked tirelessly both independently and collaboratively with our partner Schleuniger to develop and market these to meet customers’ needs”.

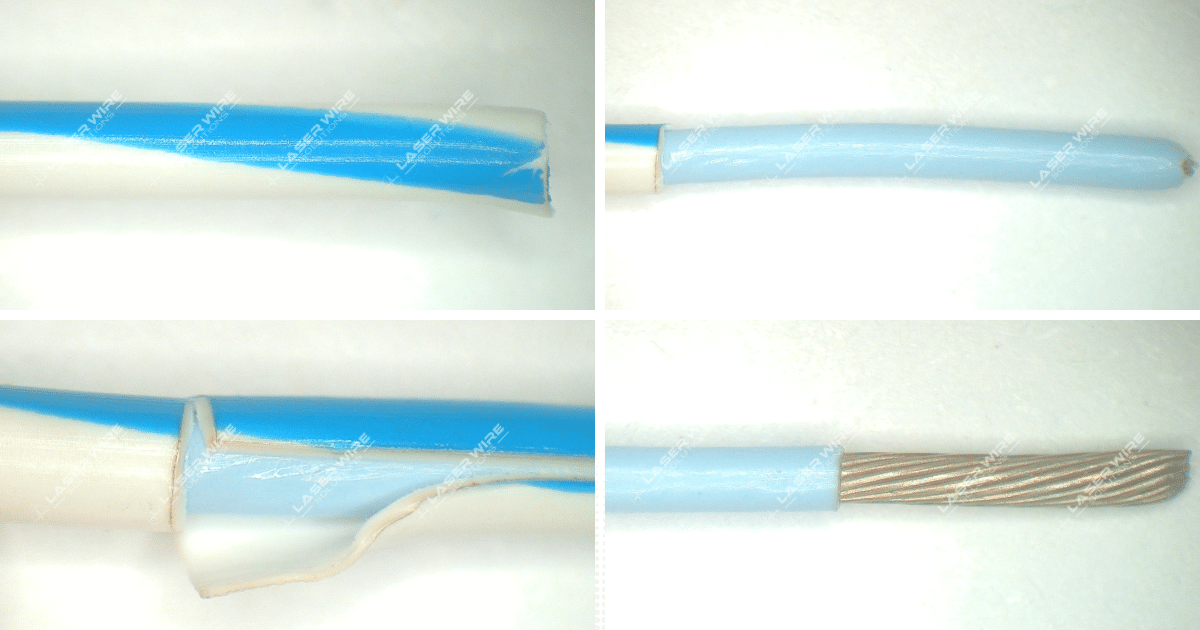

The most recent addition to the range of laser wire strippers is the Mercury-6, which is a rotary stripper unit customized for the stripping of multi-layer cables up to an outer diameter of 1.18” (30 mm). As with the company’s other laser wire strippers it gives an intrinsically perfect strip every time with no nicks and no scrapes. The laser light efficiently vaporizes a line of insulation around the wire which harmlessly reflects off the conductor or shield producing a perfect strip every time.

The Mercury-6’s optical system features both a linear and a rotary axis. The rotary axis gives the circumference cut and the linear axis moves the optics to make the slit (up to a maximum 7.84″/ 200 mm length). The optics head has a programmable focus to allow for changes in cable layer diameter. It’s a benchtop system that is simple to use and effortless to maintain. Fitted with an HMI touchscreen, strip programs can be easily configured and selected. The self-limiting laser process means that a wide range of wires and cables can be stripped in a single machine with the same set-up.

Similar in concept to the Mercury-6 is the Mercury-5, which made its debut in Munich last November at the productronica show. The Mercury-5 has been a collaborative project between Laser Wire Solutions and Schleuniger. This specific Mercury edition was introduced to strip tough outer jackets of large cables up to 0.79″/20 mm in diameter with strip lengths of up to 7.84″/ 200 mm.

Typical applications for the Mercury-5 and Mercury-6 machines are the stripping of high voltage cables used in electric and hybrid vehicles. Both the Mercury-5 and Mercury-6 machines can be fitted as in-line units into existing production lines for improved efficiency and automation.

Laser Wire Solutions will also be shining the spotlight on its new Odyssey-4. Whilst the Mercury systems feature carbon dioxide lasers, the Odyssey system uses UV laser technology. This is a highly innovative, first-of-its-kind product that was designed to handle and ablate very delicate enamel (polyimide) wires down to 50 AWG or less. Such wires are typically found in high speed data cables and in medical devices (catheters). The stripping of micron-thin polyimide insulation is clean, fast, and of an exceptionally high standard. Strip quality is verifiable with a reliable closed-loop camera vision system monitoring every stage of the process. The Odyssey-4 can also be configured to automatically strip wires inline from spool to spool using a precision wire transport system. With access to this latest innovation, medical device manufacturers now have an affordable, accurate and reliable system to help them build the next generation of miniaturised, high precision medical devices, whilst at the same time reducing scrappage, improving production efficiencies and maintaining stringent quality control.

Alongside the above, there will be a chance to see why the Mercury-2 and Mercury-4 carbon dioxide laser wire strippers continue to be so popular. The key features of the Mercury-4 are its versatility and speed. With quick change-over door fixtures, it can strip single wires, multiple wires and ribbon cables in various strip configurations: angled lines, curves, windows, cross-cuts and slits within a total strip area of 2” x 2” (50 mm x 50 mm). An impressive stripping speed of up to 80” (2000 mm) per second (dependent on material type) is achievable without compromising on quality: with /- 0.004” (0.1 mm) repeatability of results every time.

The Mercury-4 can be used as a stand-alone benchtop unit or can be interfaced to any Schleuniger Cut & Strip machine for in-line stripping with a 100% circumferential strip. The Mercury-4 is now a firm favourite with many wire processors and fully proven in the field. It is the ultimate solution to handling a broad range of insulation materials and colours.

On the opposite side of the same coin is the Mercury-2. This is a real workhorse laser wire stripper, bigger in construction than the Mercury-4 and with a larger processing area of 7” x 5” (180 mm x 120 mm) – therefore allowing for a greater number of wires to be fixtured and stripped. The Mercury 2 is also capable of in-line stripping as well as cross-cuts, slits and windows.

Staff from Laser Wire Solutions are very much looking forward to welcoming visitors to its booth 1732 and to demonstrate the full capability of the systems described above. Please bring along wire samples for testing and demonstrating proof of capability. The following team will be on hand to deal with your enquiries:

Paul Taylor – Chief Physicist and CEO

Phil Dodson – Director of Sales & Operations

Adrian Thomas – Regional Sales Manager

For more information on the show, please visit the organiser’s website.