In the ever-evolving landscape of technological advancements, Laser Wire Solutions is thrilled introduce the Odyssey-8. This new machine is the world’s most compact single wire laser stripper. This ground-breaking innovation is set to redefine wire stripping in the medical industry, combining precision engineering with cutting-edge technology.

The Best Micro Wire Stripping Method

Compact Design

The Odyssey-8 has been designed with space in mind. With its compact design, it addresses the space constraints often faced in medical device assembly. The ergonomic form factor ensures seamless integration into manufacturing processes.

Single Wire Laser Stripping Technology

At the heart of Odyssey-8 lies a revolutionary single wire laser stripping technology. Rather than spending crucial time loading wires onto a custom fixture, the Odyssey-8 is designed to process one wire at a time to achieve a faster and more precise strip.

Versatility Unleashed

Designed to handle a wide range of wire types from single conductors or twisted pairs to bifilar and trifilar wires, the Odyssey-8 is a versatile solution tailored to the unique demands of the medical sector; offering adaptability without compromise.

Impressive 3-Second Cycle Time

Without the need to load wires onto a fixture plate, the Odyssey-8 boasts an impressive 3-second cycle time. This short cycle time is critical for enhancing operational efficiency and accelerating production processes while maintaining the highest quality standards. By using a single beam to strip 360 degrees of the wire, and a unique technique to do so, it maintains a short cycle time to achieve the same results for each shift.

Handling Wires Less Than 0.2mm

With medical devices becoming more micro and less invasive, the wires used are becoming smaller and demand higher precision. The Odyssey-8 is engineered for just that. Designed to handle wires with a diameter less than 0.2mm, it is an invaluable tool for intricate and delicate medical wiring applications.

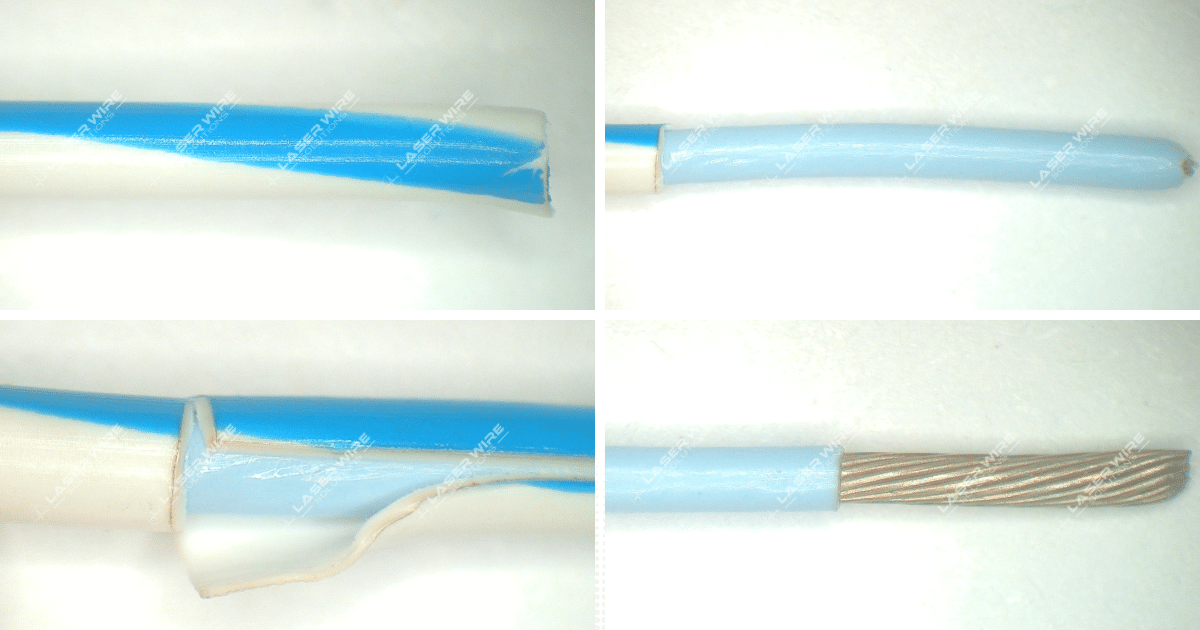

Medical Grade Material Processing

As this machine is part of our Odyssey range, it is designed to remove the following insulation materials: Polyurathane Enamel EW / EWF, Polyester Enamel PEW, Polyester-imide EIW, Polyamide-imide, Kapton, ML, among others.

The Odyssey-8 is the new preferred alternative to the traditional method of removing outer layers of insulation using rotary cones, tweezers, or scraping before the resistance welding wires to rings for catheters. These methods have been providing poor yield and quality defects for numerous medical device OEMs in the US, Ireland, and Costa Rica. The Odyssey-8 has changed the game for these manufacturers, with one stating “we wouldn’t get a clean strip like that with scraping, especially at that speed”, so join the medical device OEMs already embedding laser wire stripping technology into their production lines today.

Get a firsthand look at how this tool will revolutionize wire stripping in the medical sector here.

Join the Conversation

Follow us on LinkedIn to learn more about the Odyssey-8. At Laser Wire Solutions, we remain committed to pushing the boundaries of innovation, and Odyssey-8 is a testament to our dedication to providing tools that redefine industry standards.