Laser Wire Solutions is recognized again for its innovation flair and its commitment to growth with its international customers and partners.

We have been nominated for the Wales STEM Awards, shortlisted for both International Business of the Year and Innovation in Engineering. The awards ceremony has been pushed back from May to November owing to the Covid-19 virus.

The company’s products are much sought after by high-tech firms all over the world, particularly in the United States, with 98%+ of its turnover deriving from exports. Thanks to its international success, the business picked up a Queen’s Award for International Trade in April 2018.

Our solutions are especially suited to quality critical applications. Our particular areas of focus are the medical device market, high speed data cabling and the automotive market (the electrification of vehicles makes laser the preferred solution for stripping high voltage cables). Our technology is deployed to improve quality and accelerate time to market.

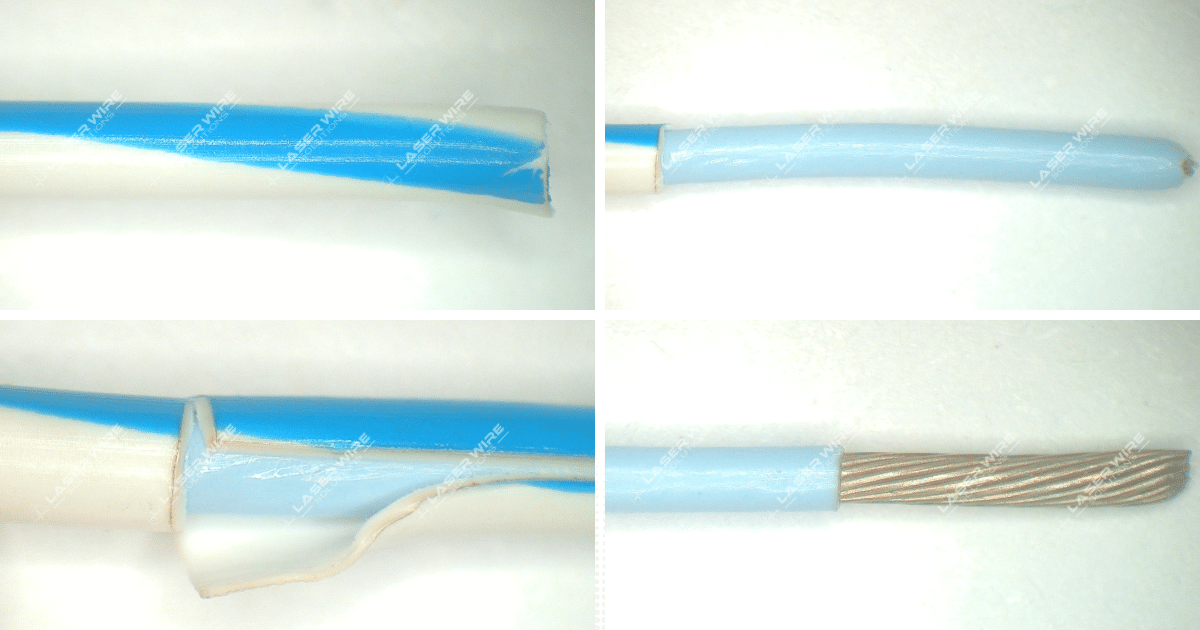

Much of the growth has been attributed to our innovation track record. In 2017 a compact UV laser system was launched and sold to large medical device manufacturers to facilitate the precision removal of tough enamel insulation from microscopic catheter wires. The process is effortless as the laser reflects off the underlying conductor to ensure no damage and the system can also be automated on a reel to reel system to ensure greater productivity and consistency of quality than traditional manual or chemical methods of wire stripping. The launch of this system also helped secure another Queen’s Award for the company in 2019 – the Queen’s Innovation Award.

Currently Laser Wire Solutions is pioneering an innovative, robotically automated system to allow precision stripping AND soldering of very tiny medical wires. This is a particularly interesting application for the development of next generation medical devices, especially ultra-sound cables, where existing technology has reached the limit of what an operator can physically assemble and is therefore causing bottlenecks in production. Laser Wire Solutions’ new system will automate this intensive, laborious task and offer far greater precision in electrical connection to ensure less scrap and a safe end-product. Use our Contact Us form to find out more.